Welding demands high quality PPE, and for good reason. A welder's working conditions are physical, strenuous and tough! They work in one of the roughest industrial environments, around numerous hazards and literally face getting burned everyday. For this reason, ANSI Z49.1 requires all welders to wear protective flame-resistant gloves.

Both welders and cutters require protective flame-resistant gloves that provide excellent heat resistance. Keep in mind though, a welding glove's material must provide more than just the standard protection from cuts, flames, heat, and sparks. Gloves must also be comfortable and offer excellent dexterity! A common reason welders take their gloves off is due to discomfort. Many of our new welding glove enhancements address this concern.

MCR Safety’s leather welding gloves are designed to protect welders from numerous welding hazards. We highlight below why we've been trusted by welders for over 40+ years now!

Leather is the main material used in welding gloves. Therefore, we thought it would be helpful breaking down the main components of leather. Here is your crash course lesson on leather gloves:

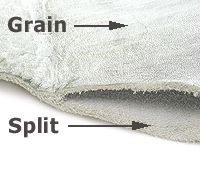

The first major component of leather gloves is the cut. Most stick welding require split leather, where Mig/Tig gloves require a grain cut.

Here is an overview of both:

Grain leather is the smooth external side of the hide. This type of leather provides durability and dexterity.

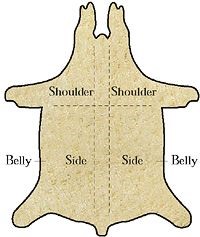

Split leather is the rougher internal side of the hide. The three different types of split leather are side, shoulder or belly split. Not all split leather is equally created. It all depends on where the leather derives.

Here is a quick breakdown of leather, which is the material most commonly used in welding gloves:

Open flames burn the naturally occurring oils in leather as well as the chemicals used in the leather tanning process, which causes the gloves to harden and char. The better leather used in welding gloves, the longer the welding glove will last.

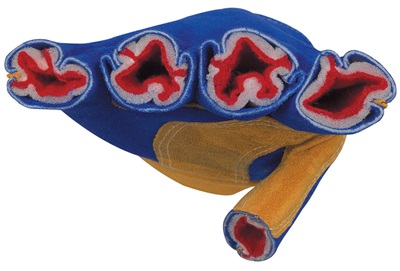

Insulated linings help protect areas exposed to high radiant energy. All leather welding gloves provide insulation and thermal protection.

However, some leather glove styles provide more protection than others, based on the type of leather and lining.

The high-loft matte fiber of a thermosock lining keeps hands warm in cold environments.

Recognized as one of the leading materials for insulation, Thinsulate™ keeps hands warm in extreme temperatures.

Made of cotton or a cotton blend, pile linings provide a soft cushioning material inside a glove.

Interlocking cotton knit fabric helps keep gloves lightweight and flexible.

This single-knit cotton fabric known for its elasticity and soft feel offers comfort at an economical price point.

The soft, cotton fleece material provides users with extra warmth and reduces chafing.

Often used as insulation from the cold and heat, foam linings create an air barrier that offers wearers protection and provides a cushioning effect.

5X stronger than steel, a DuPont® Kevlar® liner is versatile and offers users both cut- and thermal heat-protection properties.

MCR Safety’s very own HPPE cut-resistant material, Hypermax provides users with a highly cut-resistant and comfortable liner.

Boasting Nature's best insulating property, wool dries quickly, too.

Premium heavy leather welding gloves

MCR Safety's Premium welders are made from select heavy side leather. All premium gloves are sewn with 100% DuPont Kevlar thread, welted seams and a turned leather hem to protect stitching from sparks and heat. These gloves can be used for medium to high heat welding applications with temperature ranges of 300° - 400°.

Other features of premium heavy side welding gloves:

Here are some of MCR Safety’s top premium heavy side welding gloves to consider:

We are known across the industry as having a large selection of welding gloves options. Our select welding leather gloves are made from medium to heavyweight shoulder leather.

We know welders many times are looking for a competitive price. As we highlighted above, by manufacturing lower quality, shoulder cowhide leather, we are able to manufacturer lower cost alternatives. Here are a couple welding gloves to consider:

When handling hot molded products or metal materials, MCR Safety’s foundry glove provides temperature protection up to 500º, depending on the application.

Last but not least, we carry welding gear many don’t offer. We carry smaller sizes for ladies and some XXXL sizes for those with longer fingers.

*NOTE: Left Hand (LH) only available on styles 4150, 4320, and 4600Mig and Tig welding involves lower heat, when compared to stick welding, traditionally less than 200 degrees. When a welder is Mig welding, dexterity is not as important. However, when Tig welding, gloves need to be tight fitting and dexterity is extremely important to the quality of weld. While Tig welding, the welder needs to have a good feel of the rod and welding gun.

MCR Safety’s Mig/Tig gloves offer greater dexterity than heavy side welding glove and help reduces a welder’s hand fatigue. These gloves are made from thinner, softer leather including cow, pig, goat, deer, and elk grain leather.

Below are some of the most popular styles we offer:

Mig and Tig gloves are an excellent choice for circuit board manufacturing, ornamental artwork, automotive, and light manufacturing.

Welding gloves can vary significantly in cost, depending on the glove’s specific components. A thorough analysis should be conducted to assure accurate comparison of different welding gloves and glove brands.

Here are features that affect a welding gloves’ performance and cost:

Beyond what we’ve discussed above, proper welding protection selection considerations include type of heat, temperature exposure, handling time, and weight of the material being handled. Our ITC Heat Blog sums up heat testing and highlight which leather products are best suited for contact heat.