ANSI/ISEA 105-2024: A Quick Guide to Hand Protection Standards

Released in November 2024, this standard provides a comprehensive classification system for hand and arm protection against mechanical and chemical hazards. A significant update in this edition is the introduction of a standardized pentagon-shaped pictogram for glove labeling, displaying ratings for abrasion, cut, and puncture resistance (Example shown above). This uniform labeling aims to help users quickly identify the appropriate protection level for specific tasks.

Additionally, the 2024 standard emphasizes the importance of manufacturers demonstrating conformity to the claimed classifications, referencing ANSI/ISEA 125-2021 for conformity assessment. It also updates test methods to newer versions, ensuring consistency and reliability in performance evaluations.

For more detailed information, you can refer to the official announcement by the International Safety Equipment Association (ISEA).

SAFETYEQUIPMENT.ORG

Key Performance Ratings and Test Levels

The standard covers multiple factors, including abrasion, cut, puncture, and chemical resistance. Below is a summary of the primary classifications.

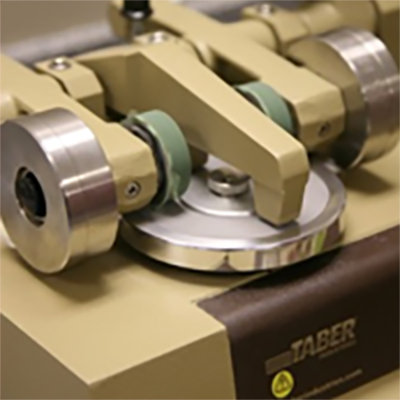

Abrasion Resistance (ASTM D3389/D3884)

Test Method: The abrasion resistance is tested using a rotating drum with a specific abrasive material (usually a sandpaper-like surface). The glove or material is placed inside the drum, and the rotating action causes wear and tear. The test continues until a specified amount of material is abraded or until holes are formed.

Purpose: It measures how well the material can withstand friction and repetitive contact.

| Level | Cycles to Failure |

|---|---|

| 0 | < 100 |

| 1 | ≥ 100 |

| 2 | ≥ 500 |

| 3 | ≥ 1000 |

| 4 | ≥ 3000 |

| 5 | ≥ 10,000 |

Example: A glove rated at Level 3 can withstand at least 1000 cycles of abrasion before showing signs

of wear or failure. This level is suitable for tasks like handling rough or abrasive materials, such as concrete or metal parts.

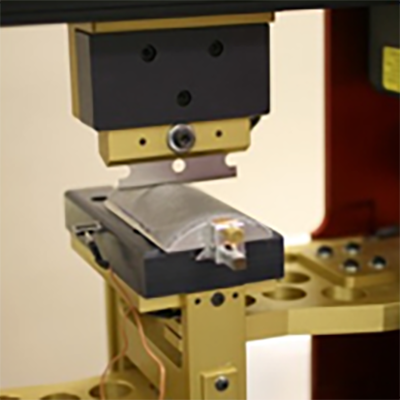

Cut Resistance (ASTM F2992-15)

Test Method: Cut resistance is typically tested using a rotating circular blade (cutter) that moves across the glove or material at a constant rate. The amount of force required to cut through the material is measured, often using a coupe test or tomodera test.

Purpose: This test evaluates the glove’s ability to resist sharp objects from cutting through the material.

| Level | Cutting Load (grams) |

|---|---|

| A1 | 200 - 499 |

| A2 | 500 - 999 |

| A3 | 1000 - 1499 |

| A4 | 1500 - 2199 |

| A5 | 2200 - 2999 |

| A6 | 3000 - 3999 |

| A7 | 4000 - 4999 |

| A8 | 5000 - 5999 |

| A9 | ≥ 6000 |

Example: A glove rated at A4 can withstand a cutting load between 1500 and 2199 grams.

This rating is useful for tasks involving sharp objects, such as working with glass or metal sheet cutting.

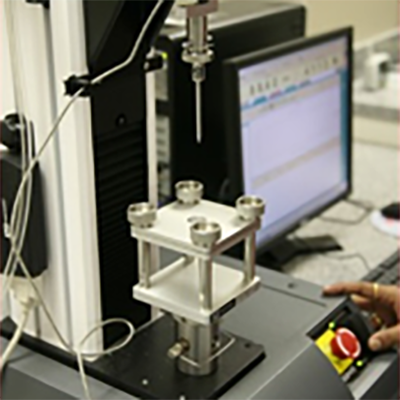

Puncture Resistance (EN 388)

Test Method: In puncture resistance testing, a sharp object is applied to the glove or material with a controlled force until it punctures the material. The force needed to penetrate the material is recorded.

Purpose: This test assesses the material’s ability to withstand punctures from pointed or sharp objects.

| Level | Force (Newtons) |

|---|---|

| 0 | < 10 |

| 1 | ≥ 10 |

| 2 | ≥ 20 |

| 3 | ≥ 60 |

| 4 | ≥ 100 |

| 5 | ≥ 150 |

Example: A glove rated at Level 2 can resist a puncture force of at least 20 Newtons up to 59 Newtons.

This level is appropriate for handling objects with sharp edges, such as metal or wood.

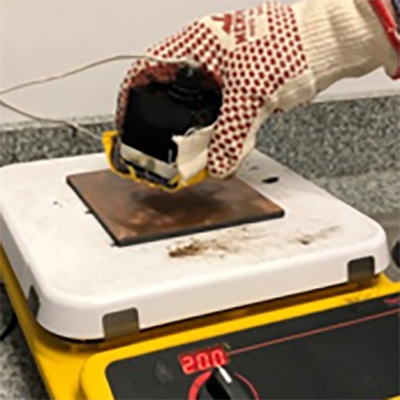

Conductive Heat Resistance (ASTM F1060-18)

Test Method: This test typically involves exposing the material to a controlled heat source, usually a metal plate or heated oven. The test measures how long it takes for the heat to transfer through the material and how much heat is conducted before it reaches the skin.

Purpose: It evaluates the glove's ability to protect the wearer from high temperatures or thermal hazards.

| Performance Level | Contact Temperature |

|---|---|

| Level 1 | Up to 80°C (176°F) |

| Level 2 | Up to 140°C (284°F) |

| Level 3 | Up to 200°C (392°F) |

| Level 4 | Up to 260°C (500°F) |

| Level 5 | Up to 320°C (608°F) |

Example: A glove rated at Level 2 can handle contact with surfaces up to 140°C (284°F) for at least 15 seconds

before a second-degree burn is likely to occur, providing the wearer with at least 4 seconds of warning time to react and avoid injury.

Conclusion

The ANSI/ISEA 105-2024 standard helps ensure workers select the appropriate hand protection for their needs. The updated pictogram labeling and refined test methods make it easier to compare gloves and determine their suitability for specific tasks.

At MCR Safety, we manufacture products that protect countless hardworking people from the most dangerous working environments. When wearing MCR Safety PPE, we want workers to know they are wearing properly tested and classified safety gear designed for the most rugged industrial worksites.

For over 50 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it’s on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It’s all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.