OSHA is a sprawling agency, covering worker safety from nurses dealing with drug-resistant infections to teens working on family farms. You could certainly read all of the information available on their website….eventually. However, there are certain areas of compliance that are specific to each industry. This is definitely true for the people working in construction and with concrete. Safety hazards exist across all areas of concrete production, from the manufacturing of Portland cement to the concrete used in constructing buildings.

This isn’t a comprehensive safety training, but it’s a good place to get started. Consider it your Concrete Safety Compliance 101 and insightful industry tips. We highlight below some of OSHA’s specific standards, useful websites pertaining to concrete, and PPE addressing these standards.

Eye Protection

A construction worksite has one of the highest rates of eye injuries when compared to other industrial industries. Eye and Face Protection is the fifth most cited construction violation.

29 CFR 1926.102 instructs that the employer shall guarantee each affected employee uses proper eye or face protection when the worker is exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation. All of MCR Safety’s eyewear styles meet the ANSI/ISEA Z87.1-2010 standard for impact protection. Wearing MCR Safety’s eyewear styles ensure that you’re adhering to the standard. The ultimate decision comes down to features, such as durability, fit, comfort, look and style.

MCR Safety’s eye protection page is an excellent resource in helping you select different lens, features, and technologies. Click the image to check out our latest technologies.

Sanitation

29 CFR 1926.51 requires that appropriate sanitation be provided by employers in the construction industry. In addition to toilets and the like, this includes clean water, non-alkaline soap (alkaline soap can cause cement burns to become even worse), and clean towels.

This regulation is particularly critical for the people working with wet concrete or concrete dust, which can cause major injuries if exposed skin is not washed promptly and correctly. Suitable eye wash stations also need to be provided when working with materials like concrete that can be hazardous.

Wet Cement

There have been a number of questions when it comes to these requirements. Can a hose be a “suitable” eye wash station? How close to hand does it need to be?

While OSHA doesn’t specify, it does mention the (non-binding, but acceptable) ANSI Z358.1-2014 standard for eye wash stations, which indicates that they need to be capable of flushing of 0.4 gallons per minute at 30 PSI for 15 minutes.

When it comes to accessibility, Z351.1 again fills in some blanks. Eyewash stations in general should be on the same floor as the worker and accessible within 10 seconds. When dealing with caustics (of which wet cement is one), the eye wash station should be immediately adjacent to the hazard.

There has also been a question of whether a pH buffer solution, which can help reduce the chances of burns from very alkaline materials, can be supplied in place of pH neutral soap and water. The answer was … maybe. Part of the purpose of using soap and water is to actually remove all the concrete from the skin not just neutralize it. If you can fully wash with the buffer solution, great. Otherwise, you need to provide soap and water as well.

Respirable Crystalline Silica

Construction work has the potential of exposing workers to unnecessary amounts of dust, potentially causing lung fibrosis and lung cancer.

29 CFR 1926.1153 pertains to respirable crystalline silica in construction work, except where worker exposure will remain below 25 micrograms per cubic meter of air (25 µg/m3) as an 8-hour time-weighted average (TWA) under any probable conditions. For additional information, we covered in-depth OSHA’s Silica dust rule in the Blog, Five Things to Know About OSHA's Silica Dust Rule.

Example of dust a worker produces when cutting concrete

Hazard Communication

29 CFR 1926.59 covers hazard communication requirements in the construction industry. OSHA requires chemical manufacturers and distributors to provide Safety Data Sheets (formerly called Material Safety Data Sheets or MSDS). Employers, on the other hand, are responsible for developing a hazard communication plan that not only lays out how things like labels and data sheets are used, but also worker training. This training needs to cover:

- The hazards of the materials being used. In the case of concrete, this would include chemical burns due to high pH levels, reactions to chromium content, and the dangers of silica dust inhalation.

- Preventive measures. This would include safe work practices, sanitation, the correct use of PPE, and first aid.

- Access to pertinent materials and facilities. Where are the SDS? Hygiene facilities? First aid kits?

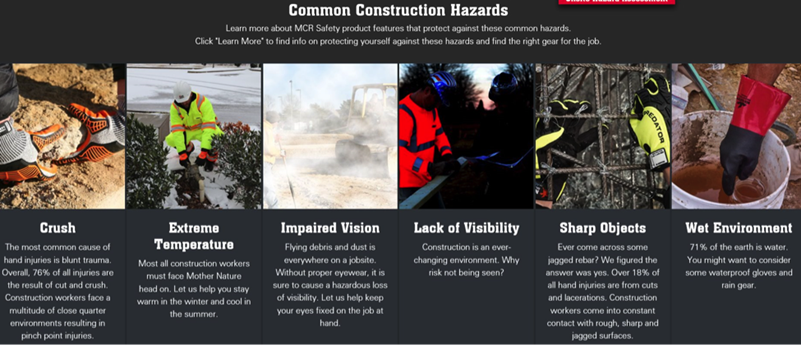

MCR Safety’s construction industry page is an excellent source for identifying construction hazards pertinent to your worksite. Click the image to see which product solutions protect against common construction hazards.

Personal Protective Equipment

29 CFR 1926 Subpart E deals with PPE in the construction industry. With rare exceptions, employers are required to provide, maintain, and replace PPE necessary to keep workers safe in hazardous conditions. When working with wet concrete, that absolutely includes waterproof gloves and boots, as well as protection for the knees (kneeling in concrete is a common cause of injury in untrained DIY hobbyists).

Eye protection and long sleeves are also critical when concrete splattering is likely to occur. In situations where workers are dealing with dry cement and large amounts of dust may be present, lined eyewear styles are necessary for keeping the dust out of a worker’s eye.

Useful Construction and Concrete Websites

Over the past six months, we’ve provided a lot of educational resources around the construction and concrete industry. Here are some useful links to keep nearby or saved as a website favorite:

- OSHA

- https://www.osha.gov/doc

- https://www.osha.gov/dsg/guidance/cement-guidance.html

- https://www.osha.gov/Publications/concrete_manufacturing.html

- Associations

- Portland Cement Association

- American Concrete Institute

- Associated Builder and Contractors

- Journals

- Construction-Today

- Concrete Construction

- Tradeshows

- BuildersShow

- World of Concrete

- ConExpo CON/AGG

PPE is what we do best

We know our safety equipment inside and out, and can help you figure out the best solutions. Need a glove that combines tactile sensitivity with excellent grip? We’ve got that!

Looking for safety goggles with 6X greater Anti-Fog protection? Not a problem, we have those too!

Not sure what it is that you need? Get in touch with our team of experts today. We’ll conduct a complete 360 assessment on your business operations and have your people protected in no time.

Construction and Concrete Glove Guide

Choosing the right gloves is a critical safety step. This is even more true for concrete workers.

About the Author

Related Articles

Concrete Safety Gear Checklist

Concrete workers understand that while concrete is used everywhere, from private homes to modern...

Five Things to Know About OSHA's Silica Dust Rule

After months of deliberation, on September 23, 2017, the Occupational Safety and Health...Latest Articles