The Bureau of Labor Statistics (BLS) reports there are over 450,000 metalworkers finding employment in the fabricated metal product manufacturing industry. Metal fabrication workers and those who have studied metalworking history know that technology is constantly changing. It's been changing for thousands of years and will continue changing even faster in the 21st century.

So, when did metalworking begin? Ancient Persian Metalworking dates back to over seven thousand years ago in metal art, with chiseled engravings on gold, silver, and alloys. Over its vast history, from Persian times to medieval Metalworking, to our modern times, there are constant improvements taking place. With everyone living in a fast-paced world, staying on top of the latest metalworking industry trends becomes a challenge.

Ancient Mesopotamia Metal Engraving

Seeing the latest trends in person or getting your hands on the hottest new metalworking tool is ideal. However, daily life and work kick in, and before you know it, an entire industry changes before your eyes within a flash. We have simplified your life by taking the time to break down the latest new trends in manufacturing and metalworking.

This article will make you aware of the top industry trends we've identified. For each trend listed below, click on the link to check out the most viewed YouTube video for that specific trend. As the old saying goes, “Seeing is believing”. Our article below is geared towards helping you stay on top of the ever-changing metalworking and manufacturing world.

Top Industry Trends

We've identified seven core trends taking place across metalworking and manufacturing. Let's highlight each of them.

Additive Manufacturing

What is additive manufacturing? It is a manufacturing process that uses computer-aided design or 3D scanners that add materials to create an object. You'll hear it come up a lot as we discuss other top trends, as it is the new frontier for prototyping new concepts..

3d printing metal has come a long way. It’s no longer just a quick method for assembling mock-ups, but it is being used in everything from aircraft engines to prosthetic limbs. Click the following image for the top YouTube video on additive manufacturing.

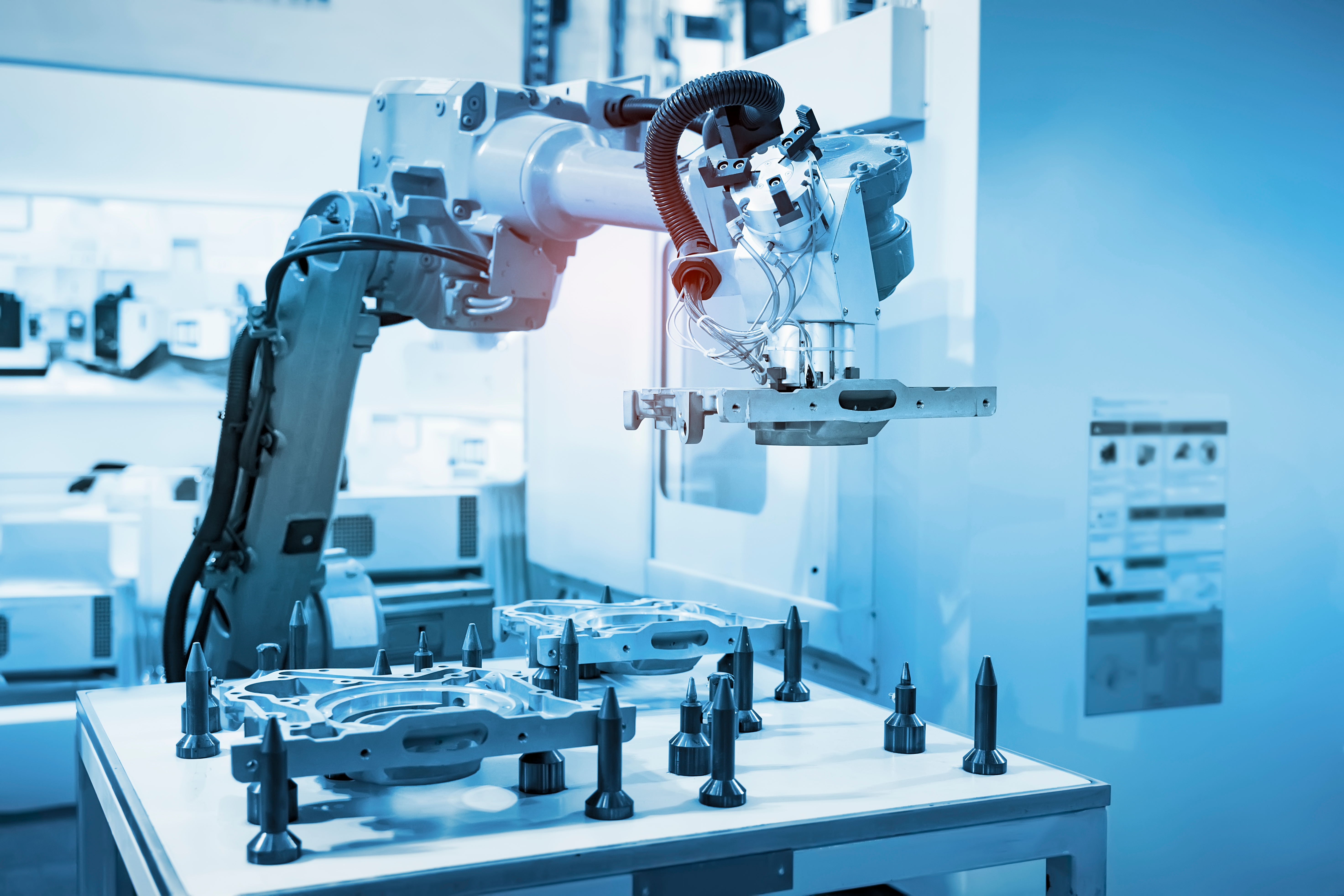

Advanced Robotics and Machine Learning

Unlike the single-task robots of the past, today's advanced robots can do a degree of problem-solving and respond to a wider variety of environmental conditions. They can make use of improved sensors, as well as communicate with other devices. In addition, because they are more flexible and better suited to the rapidly-changing manufacturing industry. Rather than being an investment that ties a business down to a single process, they empower the business to adopt emerging best practices and generate new knowledge about optimal manufacturing processes in-house. Click the image below for one of YouTube's top videos.

Nasa's Robot Issac is highly flexible and adaptable.

Big Data Analytics

With a wide variety of sensors now available that are small, accurate, and cheap, the amount of data available within manufacturing is nearly limitless. Data analysis in manufacturing allows for speed, temperature, pressure, efficiency, accuracy. The good news is all of these can be measured continuously.

Additionally, big data analytics can encompass supply chain issues, consumer demand, and the cost of fuel, utilities, labor, and raw materials. An entire industry has sprung up around analyzing large amounts of data, with both new technologies and human experts becoming critical parts of the workplace. Click the image below for one of YouTube's top videos.

Manufacturing Data Drives Our Modern Factory Operations

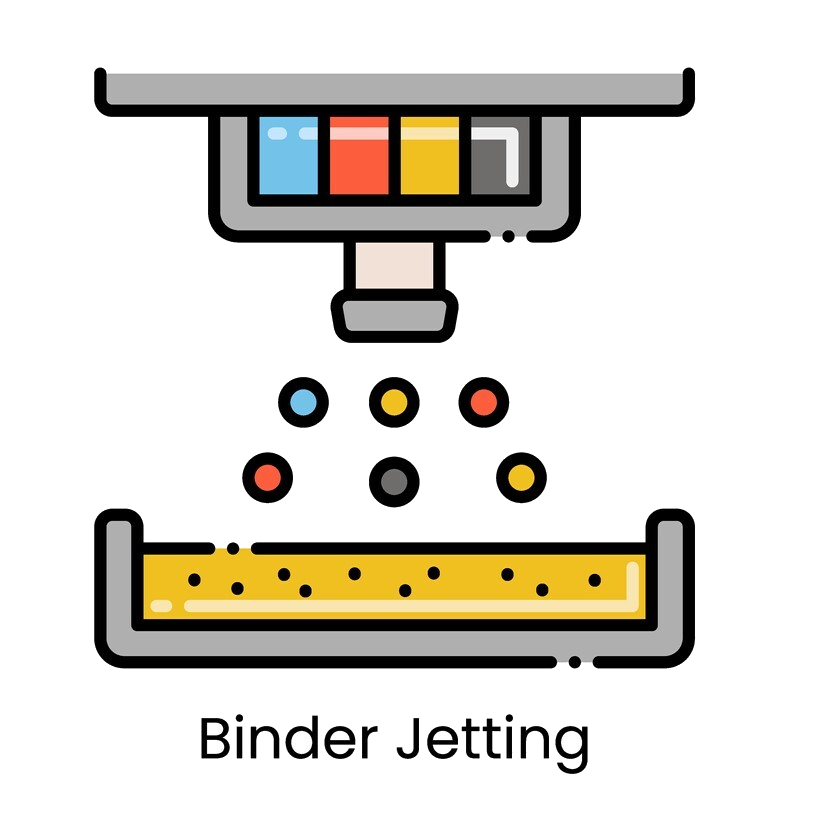

Binder Jetting

Binder Jetting, also commonly referred to powder-bed discussed below, is similar in the process to material jetting. It involves dispensing droplets of a binding agent onto powder particles through strategic layering. Since the resulting structure is relatively brittle, it is best used for architectural models and not finished products. Click the image below for one of YouTube's top videos.

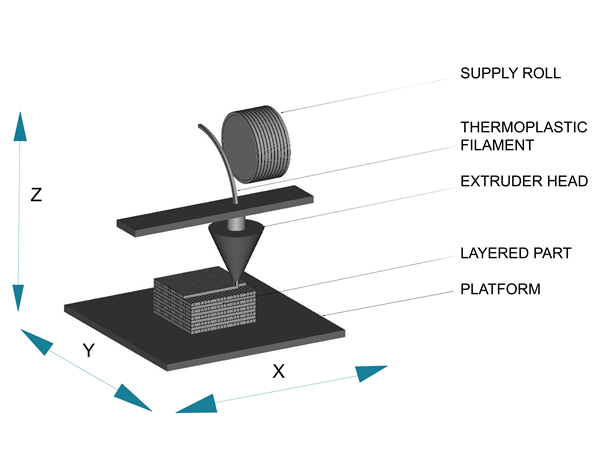

Material Extrusion and Metal Extrusion

What is material extrusion? Simply put, it is one of the seven additive manufacturing processes, where a thermoplastic filament is heated while extruded and then cools after it has been laid down. As the image shows above, the material is dispensed through a nozzle.

Material extrusion is best used for prototypes that aren't expected to hold up to extended use and are instead a quick and cheap alternative. It is also ideal for additive manufacturing in educational settings since the materials are inexpensive and readily available. Metal extrusion is a process where a cylindrical billet solid material is forced to go through a die of the desired cross-section. Click the image below for one of YouTube's top videos.

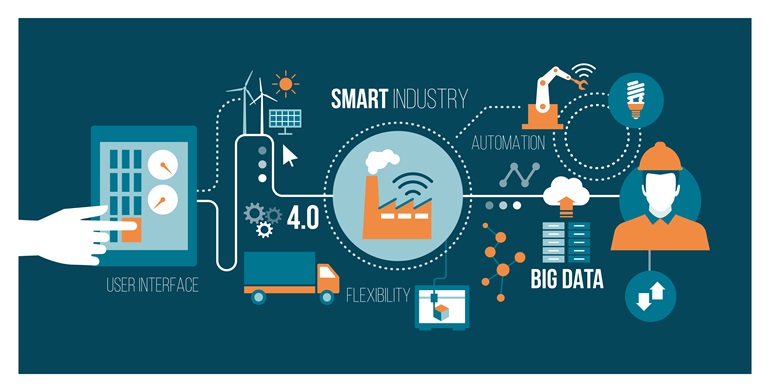

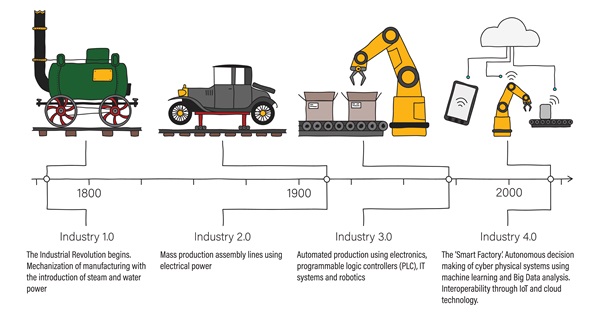

Manufacturing 4.0

What is smart manufacturing? Smart manufacturing, also commonly referred to as industry 4.0 or manufacturing 4.0, involves the intersection of big data analytics, robotics, and technology integration. When these two come together and are fully integrated using the internet, you get smart manufacturing. We cover this more in-depth below. Click the image below for one of YouTube's top videos.

Vat Photopolymerization

Vat photopolymerization 3d printing starts with a liquid photopolymer resin rather than a powder. Variations of vat photopolymerization include stereolithography, direct light processing, and continuous, direct light processing. This process is ideal for medical devices, jewelry, and other industries where acceptable levels of detail are needed.

National Institute for Metalworking Skills (NIMS)

NIMS was established in 1955 to help create a viable metalworking workforce. The organization ensures this endeavor by developing innovative metalworking standards, performance measures, and training geared toward real-life modern scenarios.

A recent development pioneered by NIMS was partnering with Edge Factor to equip companies with three free toolkits. Here is what they're sending out:

- Impactful media

- Presentation material

- Practical guidebook

All these materials are geared towards helping students and skilled workers find careers in metalworking. The following NIMS article highlights metalworking employment trends in the 21st century. Those who want to specialize in metalworking will need both practical and technical skills and validated credentials from educational institutions. It's also imperative that students cross-train across multiple disciplines, as our economy is gradually seeing occupations from multiple fields cross paths.

Lastly, new technology, as discussed above, is at the heart of all future manufacturing roles. It includes programming robots, networking devices, and writing scripts. It's all centered on new smart manufacturing solutions going into place all across the modern economy.

New Smart Manufacturing Solutions

Smart manufacturing experience is when you get a machine that turns itself off and announces what part needs to be replaced and how before it causes any damage. Using intelligent technologies in lean manufacturing is transforming manufacturing plants into highly efficient operations by utilizing digital technologies.

You get facilities that adjust their pace depending on demand projections based on the last decade worth of data. You have schedules that adjust themselves based on optimal energy use. Below is what smart manufacturing looks like, and it will continue to evolve as long as the technology does.

Redditt is America's go-to website for news and discussion around specific subjects. Users can submit content, images, and videos around subject matter they find interesting. Essentially, it is one colossus collection of forums to share content.

And, guess what? A Reddit metalworking page has over 140,000 members actively posting content around a wide range of topics. Today's active articles are focused on aluminum milling, a metal chair project, and guidance on the names of machines. We stress all this to make sure you know that Reddit is an excellent source for those wanting to stay on top of all metalworking news.

New Metalworking Hand Tools

You have a couple of different ways to find out trends related to new tools entering the market. Here are the two methods we would encourage anyone to consider:

- Pinterest is known as the world's visual discovery engine, and it's an engine that can help your metalworking knowledge. The following link has new metalworking tool as the primary search term. You can scroll Pinterest for new ideas presented around hand tools and other metal-related topics.

- Visit the Fabtech expo held every year, along with IMTS that is held every other year. All the latest new products are on display, including new safety products introduced by us. Here is a recent flyer from Fabtech showcasing all the new products on display for those who can't attend.

Common Questions

What is the history of metalworking?

- We covered ancient Persian metalworking history in the opening section above. We also highlight on our metal fabrication industry page that both the Greeks and Romans were heavily involved with creating metal objects.

Which Chinese dynasty was the first to have metalworking?

- There is some debate as to when metallurgy began in China. Most believe the Shang Dynasty was the first, as they excelled in bronze technology.

What is the employment trend in manufacturing?

- For all manufacturing employment data, check out the BLS manufacturing website. It is updated monthly, and provides insight into employment trends.

How to become a metalworker?

- You'll find insight around this topic at www.careerexplorer.com. You'll find information on what is required, the personality type of most metalworkers, and the jobs they perform.

How to set up metalworking shop?

- One of the top videos on the subject has over 500,000 total views, and it helps individuals build the perfect workshop. Also, the following video has over 13,000 likes on YouTube, guiding metalworkers on setting up a small shop.

Trends shift, but one thing does not: Safety First.

We have come a long way from when humankind first learned to hammer metals into simple objects. Metalworking technology advancements are constantly changing and improving operational efficiencies!

There is one thing that never changes and must never be forgotten, human beings play an essential part in the metalworking process. From metal material handling to the industrial mechanics working on machines, injuries will always be a concern. In regards to seeing and simplifying your PPE knowledge for metalworking, we have got you covered. Our dedicated Metal Fabrication industry page breaks down the hazards faced where gloves, glasses, and garments are required.

Click on the below image and see the metalworking PPE solutions offered.

Click the above image to leave us comments, questions, or any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's wearing premium EVA rain boots while working on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

About the Author

Latest Articles