01 Nov 11/01/2018

Our Best Heat Resistant Gloves

Are you seeking the best heat-resistant work glove available in the marketplace? If you're seeking a set of gloves that protect you from hot objects, then you are in the right place.. By the time you've reached the end of this page, you'll have a crystal clear understanding of how we determine which gloves are designed for heat resistance. You can use our left-hand navigation to jump directly to an area that best fits your needs or continue to read to better understand heat gloves in general.

At MCR Safety, we don’t expect you to put your life on the line based on third-hand promises of protection, which is why we test MCR Safety products ourselves. The Innovations Technology Center (ITC Lab) has been in operation since 2010, testing PPE for cut, abrasion, heat, puncture, impact, and tear resistance. In July of 2016, our commitment to excellence led to the ITC becoming one of the first North American testing labs to receive ISO/IEC 17025 accreditation for Hand Protection. This international standard requires companies to demonstrate a high degree of accuracy and consistency in testing protective equipment.

Burns caused by contact from hot objects occur every day.

With the Bureau of Labor Statistics (BLS) reporting over 14,000 heat-related injuries each year, and many of those occurring around hot metal, the stakes are high. Despite the dangers of workplace heat-related injuries, the ITC’s heat-resistance testing is often a misunderstood process. Rest assured, we do not just run around sticking gloves in an oven to see what happens. ANSI 105-16 conductive heat-resistance testing standards guide every heat test we conduct in the lab.

This article will cover overall burn injuries, the ITC heat testing process, and the best heat-resistant gloves we have available today.

Burns

The ITC’s heat-resistance testing serves an essential purpose, not just for ensuring quality products but for those wearing heat-resistant gloves. Countless workers rely on MCR Safety gloves to protect them against workplace burns.

A burn usually happens by direct or indirect contact with heat, electricity, sun exposure, fires, or chemical agents.

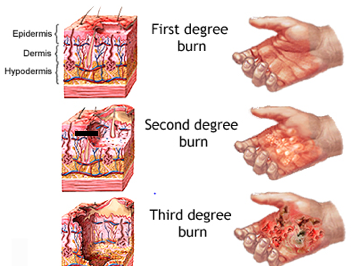

There are three levels of burns:

First-degree burn

A first-degree burn injury affects the first layer of your skin, the epidermis, with minimal skin damage. Redness and minor inflammation are signs of this burn.

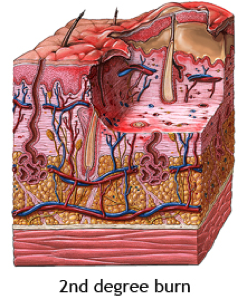

Second-degree burn

A second-degree burn injury involves the outer and middle layers of skin, the epidermis, and the dermis. Blisters will occur with this type of injury, and the skin will become extremely sore.

Third-degree burn

A third-degree burn injury that goes through the dermis and affects deeper tissues. Skin will become blackened, and charred and the area may become numb.

Here are some of the many workplace activities and hazards that can cause burns:

- Chemicals in laboratories

- Contact with hot surfaces (A 2013 Michigan State study showed that 74 percent of all injuries came from thermal burns.)

- Friction

- Gasoline, hot tar, and grease

- The heat from liquids like boiling water

- Hot machinery, metal, and workpieces

- Industrial cleaners, like rust removers and drain cleaners

- Manufacturing workplaces

- Molten metal

- Open flames and explosions

- Overheated electrical equipment

- Sun exposure

Conductive Heat Testing

MCR Safety's ITC lab tests contact heat in the palm of work gloves. And, from that testing, there are a few crucial numbers when talking about conductive heat testing. Each one of these helps determine the final score, which will be covered in our next section. Let's break down each of the primary components for contact heat scores.

Time to Second-Degree Burn

Time to Pain

Alarm time

The alarm time is the amount of time between time to pain and time to second-degree burn. In essence, alarm time measures how long it takes someone to realize there is a problem and then move away from the heat source to avoid being burned. The longer the time before the alarm sounds, it translates to the longer someone will have before a potential burn is caused.

The above image shows the ITC Lab testing for contact heat.

Conductive Heat Ratings

Conductive heat ratings measure the highest contact temperature for which the time to second-degree burn is at least 15 seconds and the alarm time is at least four seconds. In other words, it is the maximum temperature at which you have at least 15 seconds before you are injured by the heat and at least four seconds of warning during which you can move away from the heat source and save your skin from burns. Again, the more time you have, the better your chances are of not getting seriously burned.

ASTM F1060-08 is the test method used in obtaining the following levels:

- Level 0: Less than 80°C or 176°F

- Level 1: 80°C or 176°F

- Level 2: 140°C or 284°F

- Level 3: 200°C or 392°F

- Level 4: 260°C or 500°F

- Level 5: 320°C or 608°F

Before we move on to providing a summary and discussing heat-resistant gloves, we want to stress two important points:

- The contact heat test is only performed in the palm. It doesn't guarantee heat performance in the back-of-hand.

- The test is not testing for flame-resistance, only contact heat-resistance. For more on flame-resistance, you'll need to review of our FR Clothing education pages.

Long Story Short

It would be an oversimplification to say that you should always choose gloves with the highest heat safety ratings. After all, if you’re unlikely to interact with temperatures over 200°, it makes little sense to prepare for touching twice that heat level or higher. Most times, when someone requires added heat protection, the gloves’ weight will typically increase, which is not always ideal for a given application.

And the focus on heat might come at the expense of other protection that is more pertinent to your work, such as cut or puncture protection. Therefore, an accurate assessment and job analysis of your responsibilities and activities will help determine the appropriate PPE. Here are some of the factors that should be assessed: weight of the object, dexterity required, and handling time.

Once you’re familiar with the work hazards, including temperatures from both equipment and materials (including those left out in the sun), you can make a better decision about the levels of protection you need.

PPE Heat Selection Tool

At this point, you’re ready to choose a specific PPE based on the ratings you require. And we have an easy-to-use tool to help you select the best safety gear. Just click on the image below and review hand protection by heat-resistant levels.

When you need information, you need it fast. Simply put, your life and well-being are on the line. At MCR Safety, we do not mess around with getting you quick, quality information. If you require information about multiple levels of protection, such as both cut and heat resistance, you'll be able to filter across multiple performance areas.

Our Best Gloves For Contact Heat

For those working in the Metal Fabrication and Primary Metals industries where hot metals and objects are everywhere, the ITC’s meticulous heat testing is a critical resource in selecting appropriate PPE. These industries, along with those smoking meat like BBQ, grilling, food handling, and cooking, all want to know the best gloves available. The tool above is an excellent option for most; however, many like to see all products in one spot.

For those ready to purchase the best industrial heat-resistant gloves, a quick reference to our best-selling heat-resistant options is below.

Level 5 |

Level 4 |

||

|---|---|---|---|

| Material | Part # | Material | Part # |

| Cotton Canvas | 9018 | Cotton Canvas | 9132G |

| Cotton Canvas | 9128 | Leather Palms | 1400K |

| Cotton Canvas | 9136K | Leather Welders | 4750 |

| Cotton Terrycloth | 9432GFR | String Terrycloth | 9430KM |

| Leather Palms | 1711 | String Terrycloth | 9432KM |

| Leather Palms | 1211 | ||

| String Terrycloth - Kevlar | 9470K | ||

| String Terrycloth | 9450K | ||

| String Terrycloth | 9460K | ||

| String Terrycloth | 9462K | ||

| Supported Neoprene | 6944 | ||

Level 3 |

Level 2 |

||

|---|---|---|---|

| Material | Part # | Material | Part # |

| High Performance Kevlar | 93861 | Cotton Canvas | 8300C |

| Leather Palms | 1200 | High Performance - Kevlar | 93840 |

| Leather Welders | 4320 | Leather Drivers - Kevlar | 3601K |

| Leather Welders | 4600 | Leather Welders - Kevlar | 4850K |

| Leather Welders | 4500 | Leather Welders - Kevlar | 4300B |

| Supported Neoprene | 6912 | ||

| Supported Neoprene | 6950 | ||

As a reminder, level 5 styles are the highest level heat resistant gloves available today offered by MCR Safety.

Thin and With Dexterity

9178LO achieves contact heat level 3.

DuPont™ Kevlar® is the ideal choice for applications requiring cut and heat, due to its ability to withstand temperatures up to 900° F. The 9178LO is made with a 13 gauge shell, making it one of the more lightweight gloves we have that also is heat-resistant. 9178LO achieves ANSI cut A4 and ANSI contact heat level 3.

Heat and Cut

The 9687 is also made with Kevlar®9687, shown above, is one of the best coated heat-resistant gloves we offer, achieving ANSI A3 cut performance and ANSI 4 heat resistance

9687 is highly heat-resistant and cut-resistant

Also, the 9470K is a little thicker, allowing it to achieve an ANSI 5 contact heat level.

Here is a link to all ANSI 4 and 5 heat gloves made with DuPont™ Kevlar®.

Heat and Water

As mentioned, DuPont™ Kevlar® is an ideal fiber for use in gloves when heat is a concern. However, what about water? The 9784IKO shown above features a nitrile coating underneath the Kevlar®, ensuring your hands stay protected from wet environments.

Oil and Heat

Were you aware we now have a leather glove that is designed to repel oil? The 36336K comes equipped with an oil-repellant coating, making it a perfect choice for working around oil. Plus, it is rated for ANSI contact heat level 3!

Heat and Chemical

One of the best chemical gloves you can purchase are those made with neoprene. Our 6944 achieves contact heat level 5 and is made with premium neoprene! Check out our permeation database for specific chemical permeation data.

The foam lining found in 6944 is the key to its high heat resistance.

Work Gloves Designed For Dangerous Hot Objects

Our lab serves as an important component of our quality control and product inspections by providing data to ensure compliance with product specifications. It also assures you’re wearing proper work gloves engineered to keep you safe from workplace hazards, such as hot objects. If you are curious about what our ITC lab reports look like, you can check out the attached ITC lab report for reference. We know this kind of data and detailed analysis are what many users require, so feel free to request any glove’s specific report. You can also send us your current gloves, and we will test them for heat, free of charge.

For those interested in heat-resistant gloves for cooking, check out our Oven Gloves articles, which highlight many of the gloves designed for hot kitchen areas. Also, you can find all of our heat-resistant work gloves by vising our online heat-resistant work glove catalog.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's on the shop floor, an oil rig, a construction site, or shooting outdoors, we are there to provide solutions to workplace (and recreational) hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

Safety Professional Handbook

Get industry knowledge on finding the right PPE for your job and understanding safety standards like OSHA. Stay Safe!

Eyewear Buying Guide

Each year, more than 2.5 million eye injuries occur. Protect yourself by finding the right eye protection for the job.

About the Author

Latest Articles