15 Oct 10/15/2020

Understanding ANSI Z87.1

Workers employed in almost any industry can benefit from wearing specially-designed safety glasses for the eyes. Protective eyewear is personal protective equipment (PPE) that helps safeguard workers from workplace hazards. Serious eye injuries such as punctures, abrasions, and contusions can result from flying objects like chips, fragments, particles, sparks, sand, dirt, or falling objects (which can be smaller than a pinhead) striking the eye.

Some might think that wearing standard sunglasses will keep their eyes protected. While sunglasses can offer minimal Protection, unless the eyewear is rated for high impact, everyday glasses picked up at the gas station will not hold up to workplace hazards like flying debris. So how do you know if the sunglasses you want to wear have safety glass lenses? Only rigorous testing can determine that. If you’re looking for stylish sunglasses that offer exceptional on-the-job eye protection, leave the gas station sunglasses at the gas station and opt for one of MCR Safety’s popular sporty designs, like our DM3 series and SR3 series.

What is ANSI Z87.1? Fortunately, we are about to highlight everything you need to know about this very fundamental eyewear standard. Note that for those who work in industrial settings, OSHA's 1910.133 standard mandates workers must wear safety glasses that comply with ANSI/ISEA Z87. By the time you finish reading the information below, you'll understand the standard, why it's essential, and which MCR Safety glasses meet it.

The Eyewear Standard

ANSI/ISEA Z87.1-2020, the sixth revision of the voluntary eye and face protection standard, establishes performance criteria and testing requirements for devices used to protect the eyes and face from hazards that can potentially cause eye injuries. These devices include safety goggles and glasses, face shields, welding helmets worn by workers, and other eye and face protection devices used in various settings. Examples include manufacturing plants, processing facilities, utilities and transportation operations, university and research laboratories, and other occupational settings where hazards are present.

The standard sets criteria around the physical requirements, high level of impact resistance, coverage area, and permanent markings designating safety glasses as meeting the standard. It is a guide that aids the manufacturer, consumer, and the public in knowing that the product meets or exceeds specific qualities of safety. As we highlight in our article on ANSI, the simplest way to understand a standard is to recognize it as an agreed-upon way of doing something.

High Impact Testing

OSHA's recognized eyewear standard is created by the Z87 Committee on Safety Eye and Face Protection, overseen by the International Safety Equipment Association (ISEA) and adopted by the American National Standards Institute (ANSI). We will address some of the many critical updates that are a part of the revised 2020 edition, but first, let us highlight the core facets of the standard itself.

Key Markings and Ratings

- Impact Marking – The "Z87+"marking found on the lens or frame of safety glasses denotes either high mass impact testing or high-velocity impact testing. We highlight both in the next couple of bullet points. If you see a "Z87" only etched on safety glass, it means it is only rated for the optical standards and not impact Protection.

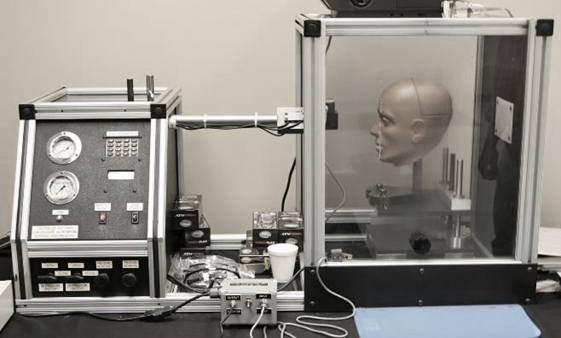

- High Mass Impact – This test involves a 500-gram pointed weight being dropped from at least 4 feet onto safety glasses mounted to a head form.

- High-Velocity Impact – In this test, a steel ball traveling 102 mph is shot at the safety glass lens. For safety goggles, the ball travels at 250 mph.

For a safety glass style to earn a Z87+ mark, the following must occur on both tests:

- In a pass or fail result, the eyewear passes.

- No break or fracture may appear on the frame or lens.

High-Velocity Impact Testing

- L Marking on Lenses – This mark represents the amount of visible light transmittance allowed by the lens, with a scale from L1.3 to L10, each with a minimum and maximum percentage possible in each ranking. We are not going to break down the percentages for each. Instead, here is a table showing the visible light transmittance for some of our top-selling lenses.

| Lens | VLT% | Average | Lens Marking |

|---|---|---|---|

| Clear | 88-92 | 90 | - |

| I/O Clear Mirror | 32-40 | 36 | L2 |

| Gray | 12-16 | 13 | L3 |

| Brown | 12-16 | 13 | L3 |

| Blue Mirror | 12-16 | 13 | L3 |

| Fire Mirror | 12-16 | 13 | L3 |

| Emerald Mirror | 12-16 | 13 | L3 |

| Silver Mirror | 12-16 | 13 | L3 |

Visible Light Transmittance and Markings

SR44R Fire Mirror Lens Showing L3 Marking

- W Markings on Lenses – A "W" marking defines the welding filter shade number. W2.0, W3.0, and W5.0 are the different filter levels, with each higher number representing a darker filter. Here are some applications where each might be used:

- W2.0 – Torch Soldering (TS)

- W3.0 – Torch Brazing, or Light Oxygen Cutting with under 1 electrode size and under 25 arc current

- W5.0 – Plasma ARC Cutting (PAC) with 20-40 arc current, Medium Oxygen Cutting with 1 to 6 electrode size and 25-150 arc current, Medium Oxyfuel Gas Welding (OFW) under 1/8 electrode size and under a 3 arc current

- UV Light – Depending on the amount of average UV transmittance, safety glasses are marked with a scale of U2 to U6, with U6 being the best and most protective against UV rays. All of MCR Safety's glasses block out 99.9% of UV light, earning a rating of U6, which is the best possible score.

SR338B showing U6 Marking

- Anti-Fog (AF) – Non-fogging glasses are critical for on-the-job safety. A marking of "X" on the lens denotes whether a safety glass has passed the anti-fog test and can resist fogging. Only our Max 6 styles are marked with an X. Other types provide some anti-fog technology; however, they don't pass the Z87 testing for anti-fog.

Specific AF Markings Used By MCR Safety

| AF Coating | Symbol |

|---|---|

| Max 36 Anti-Fog Anti-Scratch | 36 |

| Max 6 Anti-Fog | 6 |

| UV-AF Anti-Fog | Leaf Symbol |

- Coverage for Small Head Sizes – The letter "H" denotes protective eyewear designed for smaller heads.

.png?h=366&w=699&hash=8B3535C028BF614F379992330C1EBF88)

- Splash and Dust – Safety glasses that provide Protection from liquid droplets and splashes will be marked with a "D3" symbol. Dust protection will be marked with a "D4" marking, and fine dust will be marked with a "D5".

- Manufacturing Mark – Manufacturers leave their mark on their safety glasses as part of the ANSI standard. MCR Safety glasses are marked with a "C" or "US," which you can see in the image used in the UV light section.

History of Updates

The number after the dash below represents the year it was modified.

-

ANSI Z87.1-2003 updated the standards in ANSI/ISEA Z87.1-1989. Both of these versions emphasized the importance of impact as the main characteristic of protective industrial eyewear. The 2003 version had two classifications of impact ratings, and the 1989 version had only one.

-

ANSI Z87.1-2010 shifted the emphasis on eye protection to the importance of hazard-accessed Protection.

-

ANSI/ISEA Z87.1-2015 was built upon proper hazard assessment as the protective standard and addressed new technologies such as lenses with magnifying properties not previously covered in ANSI/ISEA Z87.1.

- ANSI/ISEA Z87.1-2020 is the first revision released since 2015 and the sixth revision to the standard overall.

Key Updates in 2020

In the recent standard revision, the International Safety Equipment Association (ISEA) emphasizes the importance of wearing the right eye protection for the job performed. It is called "matching the protector to the hazard," and it addresses the evolving needs of today's workers engaged in specific tasks. We list the hazard guide offered by ISEA in the next section. Here are some other updates:

- AF Coating – Includes testing, performance, and marking criteria for lenses with anti-fog properties. These standards will help minimize potential harm created by workers having to continually adjust or remove protective eyewear to see what they are doing.

- Welding Shades – It addresses new and innovative product designs such as wrap lenses and expanded welding filter shades that offer more Protection and enhanced benefit to the workers who use them.

Importance of Testing and Hazards

Our eyes are critical to our everyday experience and allow us to interact with the world around us. They enable our sense of sight and are essential in identifying friends or foes, human emotions, health and danger issues, and so much more. However, the unfortunate reality is that many hardworking people will lose their sight due to workplace injuries. The most recent data from the Centers for Disease Control and Prevention (CDC) indicates that over 2,000 eye injuries happen every day. Even injuries that are considered minor can cause pain, the inability to report to work, and lifelong vision problems.

ANSI Z87 touches on the importance of conducting regular eye and face hazard assessments. Many worksites have simultaneous exposures to hazards, which means a thorough hazard evaluation is required before deciding. Regularly revisiting and reassessing the threats will ensure the most appropriate PPE is being used. Here are a couple of links to selection guides provided by ISEA and OSHA:

MCR Safety Glasses

All of MCR Safety's protective eyewear styles meet or exceed the ANSI/ISEA Z87.1 standard, ensuring your eyes are protected from hazardous conditions. Here are descriptions and links to our vast lineup of protective eyewear that shields workers' eyes and faces from workplace hazards.

- Fogging – Temperature fluctuations can cause fogged eyewear, but not with MCR Safety's MAX6™ technology. We've developed an anti-fog page dedicated to highlighting all the different anti-fog technologies we offer. Keep in mind; only Max 6 styles pass the Z87 standard.

- Chemical Splashes – Safety goggles are designed to prevent liquids and chemical splashes from getting into the eye area.

We highlight all of our safety goggles in our recent article.

-

Dust – It can attack the eyes in workshops, woodworking studios, sawing applications, and construction sites. Sealed eyewear is the solution for working around dust.

SR5 is sealed, keeping your eyes protected from dust.

- Electrocution– Workers must wear dielectric eyewear, like our new SR3 safety glasses, made with no metal parts.

- Falling or Dropping Objects– Safety glasses will protect eyes from debris that spreads from loose and unsecured material at worksites. All of MCR Safety's glasses are tested to the high-impact standard, ensuring you're wearing the highest-rated Protection.

- Heat – Workers need to protect their eyes from the heat of industrial environments caused by furnaces, welding, other heat sources, or outside humidity. Face shields are a common type of PPE worn in such environments.

Face Shields are typically worn in hot environments, where splashing molten metal is a concern.

- Impact– Chipping, drilling, hammering, grinding, metalworking, sanding, and sawing pose dangers of chips, flying particles, metal, and other materials being thrown into the air. All of MCR Safety's glasses are tested to the high-impact standard, offering users peace of mind when wearing MCR Safety glasses.

Flying particles are always a concern in manufacturing operations.

- Radiant Energy – Harmful sparks and flying particles are a constant threat in cut and welding environments. All of our welding eyewear and cutting glasses provide superior protection and can be found here.

- Strong Winds– Blowing winds can easily cause unsecured materials at worksites to become dangerous weapons against safety. Safety goggles or sealed eyewear are common forms of Protection worn in such environments.

- Swinging Objects– Workers are always concerned about broken tree limbs, unsecured chains, tools, or ropes causing harm. All of MCR Safety's glasses are tested to the high-impact standard, which guarantees you're wearing the highest-rated Protection.

Another look at our high-impact testing machine, which guarantees you're wearing the highest rated safety glasses available on the market.

- UV Radiation – All of MCR Safety's protective eyewear styles block out 99.9% of harmful UV rays from the sun. You will find a U6 symbol on all of our glasses denoting this feature.

Polarized Safety Glasses

Reflected light and glare cause reduced visibility and the potential of hiding hazards and dangers, creating an environment where workers cannot recognize unsafe conditions.

Our new SR4 polarized safety glasses

Our polarized safety glasses meet or exceed the ANSI/ISEA Z87.1 standard and feature polarized lenses with a particular filtering layer that blocks out reflected light from below and glare from above. This maximizes your ability to see while eliminating glare and reflections that would otherwise obscure your vision, ensuring you stay safe while performing your best at work.

Additional MCR Safety Resources

Below are links to our online resources, including eye protection guides, articles, and catalog.

Anti-Fog Safety Glasses

Eye Protection Page

Fundamentals of Face Shields

Magnifiers

Online Safety Glasses Catalog

OSHA and Safety Glasses

Our Best Safety Goggles

Sealed Eyewear

Welding Glasses

Common Questions

What does the ANSI Z87.1 stamp look like?

- All ANSI Z87.1+ safety glasses should bear permanent, legible stamps like the one shown here.

Z87+ stamp found on the BearKat®safety glasses.

Is ANSI acceptable to OSHA?

- According to OSHA, ANSI and other industry consensus standards have been adopted as OSHA requirements. When it comes to protecting workers from eyewear hazards, OSHA uses ANSI Z87 as its guide. Industry consensus standards can be evidence that the industry recognizes the danger and feasible means of correcting the threat. So, yes, OSHA does see ANSI as acceptable.

MCR Safety - Protecting Eyes with Standards

At MCR Safety, we manufacture safety glasses that protect countless hardworking people from the most dangerous working environments. When wearing MCR Safety eyewear, we want workers to know they are wearing properly tested and classified safety gear designed for the most rugged industrial worksites.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it’s on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It’s all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

About the Author

Related Articles

The Importance and Significance of ANSI Standards

The ANSI standards drive the decision-making and development of all personal protective equipment...

CDC and Its Role in Protecting Americans’ Health

When it comes to issues affecting Americans' health and safety, people turn to the guidance...Latest Articles