29 May 05/29/2021

A Break Down of Butcher Gloves and Food Slicing Safety

Food industry workers in places like butcher shops, grocery stores, and restaurants are constantly slicing, dicing, and cutting food. Whether it's a sharp knife or a food slicing machine, vegetables and meats must be cut up into various sizes for countless uses. Whenever anyone is handling sharp blades, there is a possibility of a cut injury occurring, making safety an important topic.

When you examine the Bureau of Labor Statistics (BLS) cut, laceration, and puncture injury rates, several food industry occupations appear in the top 20 most commonly injured. Both food preparation workers and chefs rank in the top 10. Many of the injuries sustained in these jobs come from using knives and food slicers.

Anyone handling sharp blades should be wearing cut-resistant gloves.

It only takes one slip-up or moment of distraction for a person to lose control of a sharp instrument and find a hand or finger sliding across a sharp blade. For that reason, personal protective equipment (PPE) needs to be worn by food industry workers every time they engage with sharp tools. Workers who find employment as butchers, chefs in kitchens, supermarket staff, meat, and food processing workers need to wear PPE, primarily cut-resistant gloves.

This article will cover food industry workers regularly exposed to sharp blades, edges, and knives. It will also explore the safety gear these workers rely on to help keep their hands protected from nicks, cuts, or worse.

The Butcher and Meat Cutter

Few jobs have been around as long as butchering and meat cutting! These two professions exist around the globe and across cultures. Butchers formed guilds in England as long ago as 1272 AD! In our modern world, there were 137,500 people reported to be employed in meat-cutting jobs in 2019.

Butchers and meat cutters count the following among their job responsibilities:

- Cutting, grinding, deboning, and trimming various types of meat

- Shaping roasts with boning knives

- Inspecting food

- Weighing finished products

Many different knives are used when cutting meat.

Because these workers are focused on detailed cutting while using manual or electric cutting appliances with sharp blades to clean and trim meat and poultry, they must have a safety-first mindset. When surveyed by O*NET OnLine, 93% of butchers said they use their hands to handle and feel objects. Also, 86% of them said personal protective equipment was vital, mainly when covering the primary tool they rely on, their hands.

Sharpening a butcher's knife is a dangerous activity, one that requires cut-resistant gloves.

Butchering meat can take place anywhere and is not reserved solely for those working indoors. Those who field dress game meat (deer, sheep, pheasant, hogs, elk, etc.) or fillet fish outside need to be extra cautious to prevent accidents from occurring.

Meat Slicer Safety

To help you stay safe on the job, let's look at some professional tips for slicing meat!

Respect the equipment.

Even if you are an experienced meat slicer, you must keep from taking the dangerous nature of the machines for granted. According to OSHA, food slicers and meat grinders sustained 4,000 serious cut injuries and amputations in 2013. Be vigilant about using any meat slicer to avoid painful and potentially life-changing injuries like these.

Keep your work area clean.

A clean workspace will help you do your work faster and more safely. Instead of moving around other objects, you can focus on the job and the slicer.

Take caution during cleanup.

Keep your hands away from the slicer or grinder's sharp edges by using a cleaning device with a handle. It's imperative to wear your cut-resistant gloves during this step, too, even if you feel you have some distance from the blade.

Don't use your bare hands.

Rather than using your hand or fingers to feed food into the slicer, use a food pusher or tamper to push food towards the machine's blade. If everyone who uses a meat slicer used food tampers every time they sliced food, there would be far fewer injuries every year!

Turn it off.

Always be sure to turn off any powered food slicer when loading up new food products. Do not keep the blade running when you're changing out foods or cleaning the equipment.

Useful slicing safety websites:

- University of California, Riverside Dining Services Training Guide

- Cove Risk Safety Services

- Braher Safety

OSHA Cutting and Slicing Tips

The Occupational Safety Health Administration (OSHA) regulates all safety standards across U.S. industries. They provide standards and operational tips for anyone who operates a food slicer, including meat slicers. Employers and any individuals using a meat slicer should review OSHA's Fact Sheet, which provides insight into safety tips while slicing food and meat.

For food and meat slicing, these three OSHA standards apply:

- 1910.212 Machine Guarding

- 1910.138 Hand Protection

- 1910.147 Control of Hazardous Energy

You can click the links above to learn more about each standard. For example, standard 1910.147 requires a lockout/tagout program to be established when guards are removed from cutting machines. The unit must also be unplugged to ensure nobody accidentally starts it.

OSHA also mentions the need for proper training to keep workers safe. Training should cover everything from understanding the hazards associated with slicers and grinders to knowing how to operate them safely, including when to remove safeguards and when not to. The uses and limitations of hand protection should also be included in the training program. In OSHA's Fact Sheet, they stress how important it is for workers to wear cut-resistant gloves anytime they come into contact with the blades.

Also, OSHA's restaurant website is an excellent resource for any food service worker who wants to understand safe work environments better. Anyone serving as a line cook, prep cook, or culinary student can benefit from observing the many safety tips provided by OSHA. Here are some of the main points from their website that relate to cut safety:

- Cleanup Cuts – Washing dishes is an area prone to cut hazards.

- Food Preparation Cuts – There are several cut-resistant glove options to consider wearing as PPE when using sharp knives or cleavers.

- Serving Cuts – When cutting bread or picking up broken glass, cut injuries can quickly happen.

Regarding washing dishes, MCR Safety provides more insight into hazards presented from it in our Dishwashing Gloves article.

Now let's talk about another sharp kitchen hazard: mandoline slicers!

What Is a Mandoline Slicer?

A mandoline features a flat surface equipped with a sharp blade, allowing a person to slice vegetables and fruits swiftly by sliding the food back and forth across the fixed blade (see above image). Mandolines are excellent tools because they allow you to quickly and efficiently slice large amounts of vegetables without being slowed down by a chef's knife. And they're not just for professional kitchens; many home cooks use mandolines because they save time and effort while producing uniform slices.

Like all machines, however, a mandoline can cause injury to a person if not used properly. Therefore, it's essential to understand the tool and its safety risks.

Mandoline Safety

The last thing anyone wants is an injured finger during food preparation activities. While mandolines may not be as hazardous as other cutting tools, caution should be observed whenever a sharp blade is used. Make sure you're not distracted when operating this tool, as you can quickly run your fingers over the sharp blade if you're not paying attention.

It's imperative you use the mandoline's food guard or hand protector to move the food back and forth across the blade and not use your bare hand to do so. Never try cutting food without using the guard! Even if you have sliced a thousand pounds of fruits and vegetables, you still need to use the safety guard to protect yourself from an accidental cut injury.

Although a mandoline has safety features in place, there is always a possibility of injury. Many mandoline cut injuries occur when swapping out attachments or working with brand new blades. To avoid these dangers, cut-resistant gloves are a must, as they keep your fingers protected from the sharp edges and blades. We discuss this type of PPE more in-depth next.

Before we move on, here are some helpful mandoline safety websites:

Cut-Resistant Gloves

We have talked a little bit about wearing cut-resistant gloves when handling knives, slicers, and mandolins, but let's go into more detail. Sometimes, people only think about cut-resistant gloves in terms of heavy-duty industries. However, the food preparation industry is a significant user of cut-resistant gloves, and the need shows up when performing the kinds of activities we've covered above.

MCR Safety's cut-resistant gloves are designed for countless workplace activities. We understand that different industries have different needs, so we offer so many cut-resistant glove options. Within food-related occupations, not everyone requires the same amount of protection, so we offer numerous cut levels and options. In total, there are nine ANSI cut levels, A2 to A9, with the higher number offering the most cut protection. For those seeking the best cut protection, users should seek out A7 to A9 protection.

What are butcher gloves? Most people think of food preparation settings for these gloves and only consider chain mail gloves, as this form of protection provides users with extreme puncture and stab-resistant protection from knives. However, as webrestaurant.com identifies, different job responsibilities determine the level of protection required by various food workers. Individuals who are involved in lighter food preparation activities may opt for a lower-level cut-resistant glove. However, as one begins more intense food preparation activities, such as butchers who are slicing and cutting, one will need to consider cut-resistant gloves that offer higher ANSI cut protection.

For meat slicers and butchers who work with razor-sharp blades, reinforced steel options should be regarded as the minimum protection level. These products often go beyond A5 levels of cut protection, shown below. The MCR Safety Steelcore® products listed below are made of FDA-approved materials and feature polyester-wrapped stainless steel fibers.

MCR Safety's brand for gloves using stainless steel and polyester.

All of these gloves are cut-level A7 and higher.

9381, singled-sided blocks, and 9382, double-sided blocks, offer the highest ANSI cut protection score possible with A9 cut-resistance.

Also, the 9381 comes with single-sided blocks, and the 9382 comes with double-sided blocks. Some users prefer dotted glove options to help add grip when butchering slippery meat. Also, many users will opt for putting heavier-weight disposable gloves over the top of Steelcore® gloves to help keep them clean and shield their hands more from chilled meat.

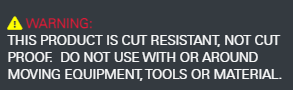

Keep in mind: there is no such thing as a cutproof glove. The job of a cut-resistant glove is to resist sharp objects from cutting your hand. The higher the ANSI cut score of a glove, the better its performance in protecting against cuts from sharp objects. And never forget that the purpose of a cut-resistant glove is to protect your hand and fingers. If a part of the glove is damaged due to touching a sharp blade or edge, be thankful it was not your finger. Be sure to replace gloves as soon as they become damaged to ensure top-quality protection; working with a damaged glove could lead to injury.

Cut-resistant gloves come in many materials, thicknesses, and levels of flexibility. For those who want to understand cut protection better, here are some resources MCR Safety has created on the subject:

MCR Safety does not offer a chainmail butcher glove. If extreme stab resistance and puncture resistance is required, you may want to consider pursuing these styles. If you leave us a message below, we can get you in touch with one of our industrial distribution partners who offer this option.

General Warnings

MCR Safety cut-resistant gloves mentioned are not cutproof. Also, these gloves will not resist the intensity of power-driven blades found on saws and power tools.

Common Questions

What is the best mandoline slicer?

- This Fullstar Mandoline Slicer is the mandoline with the highest ranking on Amazon. With nearly 13,000 ratings, this item has proven its worth in home and commercial kitchens alike!

How do I use a mandoline slicer?

- Great question! Using a new tool can be intimidating, but this step-by-step guide will walk you through the process. Don't forget always to use the guard, and if you are starting with a vegetable that is too big, cut it into smaller pieces first.

How do I clean my meat slicer?

- Safety-minded individuals ask this question all the time. How can you safely clean your meat slicer? The first step is to ensure that the slicer is completely turned off and unplugged and that the blade is set to 0. From there, you can follow these steps!

How do I sharpen the blade of my meat slicer?

- This site walks you through the step-by-step process of sharpening your meat slicer blade. Remember that when sharpening begins, you need to be wearing cut-resistant gloves on both hands!

MCR Safety Protects People From Sharp Objects

We know that anyone cutting, slicing, or chopping food is at risk of cut injuries. Workers and individuals must take PPE seriously and understand the proper safety measures needed when cutting foods. One of the most significant safety decisions a user can make is wearing cut-resistant gloves, which provide wearers with an extra dose of confidence when working with sharp blades.

If you have any questions about our safety gear, please leave us a message below.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's in a restaurant kitchen, on the shop floor, an oil rig, or a construction site, we are there to provide solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

Eyewear Buying Guide

Each year, more than 2.5 million eye injuries occur. Protect yourself by finding the right eye protection for the job.

Safety Professional Handbook

Get industry knowledge on finding the right PPE for your job and understanding safety standards like OSHA. Stay Safe!

About the Author

Related Articles

Covering Insights into Cut Resistant Sleeves

Most often, sleeves are worn in conjunction with cut-resistant work gloves. MCR Safety offers...

The Importance and Significance of ANSI Standards

The ANSI standards drive the decision-making and development of all personal protective equipment...

Our Best Dishwashing Gloves Explained

For those who might be thinking, it's only a little hot water and dish soap, think again....

Our Top 10 Best Oven Gloves

When it comes to heat-resistant PPE, MCR Safety has an incredible selection of gloves to help...

PPE: Definition, Meaning, Gear, and Equipment

Many industries and jobs have terms they shorten into acronyms to save everyone a mouthful of...Latest Articles