Understanding Solvents and PPE for Chemical Safety

Posted by Anthony Webb on Apr 8th 2025

Solvents are indispensable across various industries, from chemical processing and pharmaceuticals to aviation maintenance and manufacturing. These substances are critical in cleaning spray guns, degreasing parts, and preparing surfaces for coating. Solvents range from everyday substances like water to more hazardous chemicals such as acetone, benzene, and toluene, which pose significant health risks if not handled properly. The OSHA PPE guidelines and Code of Federal Regulations on Hazardous Waste highlight how widespread solvent use affects millions of workers, underscoring the need for stringent safety measures.

Common solvents like ethanol, acetone, and ethyl acetate are used extensively in industries ranging from cleaning and pharmaceuticals to windshield de-icing and paint thinning. While these chemicals offer specialized benefits, they can pose serious health and environmental risks without adequate protective measures. MCR Safety offers an extensive range of chemical-resistant gloves and PPE solutions to protect workers from solvent exposure. Products like our CP14R butyl rubber gloves and 5319 Nitri-Chem™ nitrile gloves provide superior resistance to aggressive solvents, ensuring worker safety without compromising productivity.

This overview highlights the indispensable role of solvents in modern industries and emphasizes the critical importance of proper PPE selection. By combining regulatory compliance with industry-leading protective gear, businesses can create safer work environments to protect their most valuable asset—their people.

What is a solvent?

Solvents are substances that dissolve other materials, known as solutes, to create solutions. They play a vital role in numerous industries, from cleaning and manufacturing to chemical processing and pharmaceuticals. Whether cleaning spray guns, removing grease, or preparing surfaces, solvents help keep operations running smoothly. They range from everyday substances like water to hazardous chemicals like methanol and ethyl acetate.

Because solvents are so widespread in industrial and consumer products, millions of workers are exposed to potentially harmful chemicals yearly. Without proper handling and protection, these solvents can cause skin irritation, respiratory issues, and long-term health problems. That’s why it is critical to understand how to handle them safely and choose the right personal protective equipment (PPE).

Types of Solvents: Polar vs. Nonpolar

A good rule of thumb is “like dissolves like”—polar solvents dissolve polar substances, while nonpolar solvents dissolve nonpolar substances. Solvents are generally classified into two types based on how they interact with different materials:

- Polar Solvents: These dissolve water-based or ionic substances like salts and sugars. Common polar solvents include water, ethanol, and acetone. They're widely used in cleaning, pharmaceuticals, and laboratory settings.

- Nonpolar Solvents: These are best for dissolving oils, grease, and hydrocarbons. Solvents like benzene, toluene, and hexane fall into this category and are commonly used in paint thinners, adhesives, and industrial degreasers.

Why are solvents used?

Solvents are primarily used for cleaning and dissolving substances, but they also play a key role in processes like paint thinning, adhesive removal, and chemical extractions. Whether working on a large industrial project or a simple DIY task, solvents make it easier to prep surfaces, clean up, and maintain product quality.

For example:

- Acetone is widely used for cleaning tools and removing adhesives.

- Ethanol is common in disinfectants and pharmaceuticals.

- Toluene helps dissolve paints and coatings.

While solvents are helpful in many applications, they can pose serious health risks if proper PPE isn’t used. That’s where MCR Safety steps in, providing gloves, goggles, and protective gear specifically designed to keep workers safe from solvent exposure.

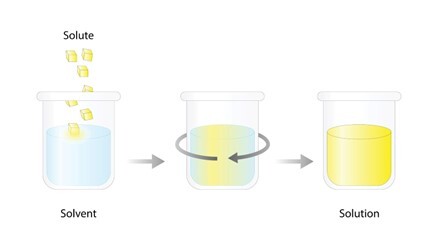

Solute vs. Solvent

At the core of understanding solvents is knowing how they interact with solutes to form solutions.

- A solute is a substance that dissolves in a solvent. Solutes can be solid, liquid, or gas. In a homogeneous solution, the solute disperses evenly, while in a heterogeneous mixture, it remains unevenly distributed. The concentration of a solution depends on the ratio of solute to solvent.

- A solvent is the medium that dissolves the solute, most commonly a liquid but sometimes a gas or solid. Solvents break down solute particles, spreading them evenly throughout the solution. The amount of solute a solvent can dissolve depends on temperature and solubility.

Key Takeaways:

- Solute = the dissolved substance (e.g., salt in water)

- Solvent = the dissolving medium (e.g., water in saltwater)

- "Like dissolves like" = polar solvents dissolve polar solutes, and nonpolar solvents dissolve nonpolar solutes

Examples of Common Solvents and Solutes

Understanding real-world applications makes these concepts more relatable:

Common Solvents:

- Ethanol (C₂H₅OH) – Found in disinfectants, perfumes, and fuel additives

- Methanol (CH₃OH) – Common in industrial processes and fuels

- Acetone (C₃H₆O) – A polar solvent widely used in nail polish removers and paint thinners

- Toluene (C₆H₅CH₃) – A nonpolar solvent used in paints and coatings

- Ethyl acetate (C₄H₈O₂) – Frequently used in adhesives and coatings

Common Solutes:

- Sodium chloride (NaCl) – Table salt, dissolves in water

- Sugar (C₁₂H₂₂O₁₁) – Dissolves in water to create sweet solutions

- Carbon dioxide (CO₂) – Dissolves in liquid to create carbonation

- Oxygen (O₂) – Dissolves in water, essential for aquatic life

Solvent Hazards: Risks to Hands, Arms, and Eyes

Workers who handle solvents face significant health risks due to direct exposure and potential absorption, particularly to their hands, arms, and eyes. Solvents' chemical composition determines their hazard level, but many are highly toxic, corrosive, or irritating, posing both immediate and long-term dangers.

Primary Risks to Hands and Arms

- Skin Irritation & Chemical Burns – Solvents like acetone, toluene, and methyl ethyl ketone (MEK) can strip away natural skin oils, leading to dryness, cracking, and dermatitis. Stronger solvents may cause chemical burns.

- Absorption into the Skin – Some solvents, including benzene, methanol, and carbon disulfide, can penetrate gloves and skin, entering the bloodstream and causing systemic toxicity.

- Nerve Damage & Organ Toxicity – Hexane and methyl n-butyl ketone (MBK) can cause peripheral nerve damage, leading to permanent numbness or motor dysfunction. Repeated exposure may also harm the liver and kidneys.

Dangers to the Eyes

- Severe Eye Irritation – Solvents like xylene, methanol, and chloroform can cause intense burning, redness, and swelling.

- Chemical Burns & Corneal Damage – Exposure to strong acids, alkalis, or highly volatile solvents can result in permanent corneal damage or blindness.

- Vapor Exposure & Vision Impairment – Prolonged exposure to solvent vapors, especially toluene and methylene chloride, may lead to blurred vision, dizziness, and headaches.

Solvents pose serious risks to workers handling them, making the use of proper personal protective equipment (PPE)—such as chemical-resistant gloves, safety goggles, and protective sleeves—essential for workplace safety. Following safety protocols can also help prevent severe injuries.

Personal Protective Equipment (PPE) for Solvent Safety

Exposure to solvents poses significant risks to workers' hands, arms, and eyes, making proper personal protective equipment (PPE) essential. According to OSHA Standard 29 CFR 1910.132, employers must provide appropriate PPE to minimize these hazards, including gloves, goggles, and face shields.

Hand and Arm Protection

Solvents can cause chemical burns, dermatitis, and systemic toxicity through skin absorption. Proper gloves must be selected based on the type of solvent encountered. OSHA 29 CFR 1910.138 requires that gloves provide adequate protection from chemical exposure, punctures, and abrasions.

- Chemical-Resistant Gloves: Made from nitrile, butyl rubber, neoprene, or Viton™, these gloves resist penetration from solvents such as acetone, toluene, and methylene chloride.

- Barrier Protection: When handling solvents, ensure gloves cover the hands and forearms fully, as splash contact can quickly lead to skin irritation or absorption.

Eye and Face Protection

Solvent splashes and vapors can cause severe eye irritation, corneal damage, and chemical burns. Under OSHA 29 CFR 1910.133, eye protection is required when workers are exposed to chemical hazards.

- Chemical Splash Goggles: Provide a tight seal around the eyes, preventing solvent splashes and fumes from causing irritation or damage.

- Face Shields: Handling large volumes of solvents should be worn with goggles.

OSHA PPE Matrix

We identified 10 of the top solvents commonly used across industries by referencing OSHA’s PPE guidelines and verified their classification as solvents using the Code of Federal Regulations on Hazardous Waste. In the matrix below, we highlight these solvents, alongside OSHA’s polymer recommendations for PPE, ensuring proper protection against chemical exposure. Following the matrix, we showcase MCR Safety’s top PPE products and specific chemical resistance scores based on EN 374 standards.

|

Industrial Use Ranking |

Chemical |

Neoprene |

Latex/Rubber |

Butyl |

Nitrile |

Industries |

Used For |

|

1 |

Acetone |

G |

VG |

VG |

P |

Automotive, manufacturing, cosmetics (nail polish remover) |

Cleaning, degreasing, paint thinners, producing plastics and fibers |

|

2 |

Ethyl alcohol (Ethanol) |

VG |

VG |

VG |

VG |

Healthcare, pharmaceuticals, food processing, cosmetics |

Cleaning agents, sanitizers, as a solvent in pharmaceuticals |

|

3 |

Toluene |

F |

P |

P |

F |

Paints and coatings, chemical manufacturing, printing |

Paint thinners, adhesives, chemical synthesis, as an octane booster in fuels |

|

4 |

Xylene |

P |

P |

P |

F |

Chemical, petrochemical, printing, rubber processing |

Cleaning, thinning paints and varnishes, rubber production, leather industries |

|

5 |

Methyl ethyl ketone |

G |

G |

VG |

P |

Aerospace, automotive, construction |

Resins, coatings, adhesives, cleaning applications |

|

6 |

Ethyl acetate* |

G |

F |

G |

F |

Paint, printing, food processing, pharmaceuticals |

Paints, coatings, adhesives, as a flavoring agent in food |

|

7 |

Benzene* |

P |

P |

P |

F |

Petrochemical, plastics, rubber (usage restricted in many countries) |

Chemical synthesis, especially in producing plastics, resins, and synthetic fibers (though highly regulated due to carcinogenic risks) |

|

8 |

Chloroform* |

G |

P |

P |

F |

Pharmaceuticals, laboratories (less common in modern industry due to safety concerns) |

Solvent in chemical synthesis, though its use has decreased due to toxicity concerns |

|

9 |

Hexane |

F |

P |

P |

G |

Food processing, textiles, printing, adhesives |

Extracting vegetable oils, adhesives, cleaning |

|

10 |

Methyl alcohol (Methanol) |

VG |

VG |

VG |

VG |

Chemical manufacturing, automotive, energy, pharmaceuticals |

Solvent, fuel additive, antifreeze, chemical feedstock |

MCR Safety’s Top Chemical-Resistant Gloves

|

Chemical Name |

Chemical Class |

CAS |

Material Series |

Lined / Unlined |

BTT MINUTES |

Polymer |

Glove Type A, B, or C |

Level 2 or Above |

|

Toluene |

Aromatic hydrocarbon |

108-88-3 |

5319 |

Unlined |

>10 minutes |

Nitrile |

A |

A,J,K,L,M,N,O,P,T |

|

Toluene |

Aromatic hydrocarbon |

108-88-3 |

5339S |

Unlined |

>10 minutes |

Nitrile |

A |

A,J,K,L,M,N,O,P,T |

|

Toluene |

Aromatic hydrocarbon |

108-88-3 |

5350 |

Unlined |

>10 minutes |

Nitrile |

A |

A,G,J,K,L,M,N,O,P,S,T |

|

Ethyl acetate |

Ester |

141-78-6 |

CP14 |

Unlined |

>120 minutes |

Butyl |

A |

A,B,C,I,K,L |

|

Ethyl acetate |

Ester |

141-78-6 |

CP14R |

Unlined |

>120 minutes |

Butyl |

A |

A,B,C,I,K,L |

|

Ethyl acetate |

Ester |

141-78-6 |

5350 |

Unlined |

>10 minutes |

Nitrile |

A |

A,G,J,K,L,M,N,O,P,S,T |

|

Acetone |

Ketone |

67-64-1 |

CP14 |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,I,K,L |

|

Acetone |

Ketone |

67-64-1 |

CP14R |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,I,K,L |

|

Acetone |

Ketone |

67-64-1 |

CP25 |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,K,L,O |

|

Acetone |

Ketone |

67-64-1 |

CP25R |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,K,L,O |

|

Methanol |

Primary alcohol |

67-56-1 |

CP14 |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,I,K,L |

|

Methanol |

Primary alcohol |

67-56-1 |

CP14R |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,I,K,L |

|

Methanol |

Primary alcohol |

67-56-1 |

CP25 |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,K,L,O |

|

Methanol |

Primary alcohol |

67-56-1 |

CP25R |

Unlined |

>480 minutes |

Butyl |

A |

A,B,C,K,L,O |

|

Methanol |

Primary alcohol |

67-56-1 |

6845 |

Lined |

>60 minutes |

Latex |

B |

A,K,L,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5110 |

Unlined |

>10 minutes |

Latex |

A |

K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5250 |

Unlined |

>10 minutes |

Latex |

A |

K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5090B |

Unlined |

>10 minutes |

Latex |

A |

K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5290P |

Unlined |

>10 minutes |

Latex |

A |

K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6912 |

Lined |

>60 minutes |

Neoprene |

A |

A,K,L,O,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6914 |

Lined |

>60 minutes |

Neoprene |

A |

A,K,L,O,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6922 |

Lined |

>480 minutes |

Neoprene |

A |

A,J,K,L,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6932 |

Lined |

>60 minutes |

Neoprene |

B |

A,K,L,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6944 |

Lined |

>10 minutes |

Neoprene |

B |

K,L,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6948 |

Lined |

>480 minutes |

Neoprene |

A |

A,J,K,L,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6950 |

Lined |

>480 minutes |

Neoprene |

A |

A,J,K,L,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6962 |

Lined |

>60 minutes |

Neoprene |

A |

A,K,L,O,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5435 |

Unlined |

>60 minutes |

Neoprene |

A |

A,J,K,L,M,N,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5430 |

Unlined |

>30 minutes |

Neoprene |

A |

A,K,L,M,N,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5409S |

Unlined |

>30 minutes |

Neoprene over Latex |

A |

A,K,L,M,N,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5309 |

Unlined |

>10 minutes |

Nitrile |

A |

J,K,L,M,N,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5319 |

Unlined |

>30 minutes |

Nitrile |

A |

A,J,K,L,M,N,O,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5319E |

Unlined |

>10 minutes |

Nitrile |

A |

J,K,L,M,N,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5339S |

Unlined |

>30 minutes |

Nitrile |

A |

A,J,K,L,M,N,O,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

5350 |

Unlined |

>60 minutes |

Nitrile |

A |

A,G,J,K,L,M,N,O,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6452S |

Lined |

>30 minutes |

PVC |

A |

A,K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6454S |

Lined |

>30 minutes |

PVC |

A |

A,K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6712F |

Lined |

>480 minutes |

PVC |

A |

A,K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6714FF |

Lined |

>60 minutes |

PVC |

A |

A,K,L,M,P,S,T |

|

Methanol |

Primary alcohol |

67-56-1 |

6632 |

Lined - Seamless |

>60 minutes |

PVC |

A |

A,K,L,M,N,O,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

MG9645 |

Lined - Seamless |

>30 minutes |

PVC |

A |

A,K,L,M,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

MG9648 |

Lined - Seamless |

>30 minutes |

PVC |

A |

A,K,L,M,P,T |

|

Methanol |

Primary alcohol |

67-56-1 |

N2659HVLL |

Lined - Seamless |

>30 minutes |

PVC |

A |

A,K,L,M,P,T |

MCR Safety Product Spotlight

MCR Safety offers a range of high-performance PPE designed for maximum protection in industrial environments, complementing OSHA's polymer recommendations and the solvent compatibility matrix. Let's highlight some of the top-selling products in the glove charts and some of the leading eye protection we offer to protect eyes from solvent hazards.

The CP14R 14-inch butyl rubber glove stands out for chemical-resistant hand protection. Offering superior impermeability against acids, alcohols, esters, and ketones, this glove is ideal for aviation maintenance and mechanics who work with harsh chemicals.

Butyl Rubber Glove Protection

For those requiring nitrile options, our 5319 Nitri-Chem™ flock lined nitrile gloves deliver exceptional puncture resistance and chemical protection, while also being latex-free—perfect for individuals with latex sensitivities.

Flock Lined Nitrile Gloves

MCR Safety's 104PF XO Skeleton headgear, with an integrated clear face shield, provides reliable facial protection against liquid splashes. It features a MAX6® premium anti-fog coating for optimal clarity in extreme environments.

Anti-Fog Face Shield

Lastly, for comprehensive eye protection, the HB510PF Hydroblast® HB5 Series safety goggles offer a soft, snug seal, D3-D5 splash and dust ratings, and premium anti-fog coating, ensuring a secure and comfortable fit even in the toughest conditions.

Splash-Resistant Safety Goggles

These products, engineered with precision and safety in mind, are designed to meet the demands of today’s most challenging work environments.

Solvent Protection

When working with industrial solvents, safety goes beyond just following procedures—it’s about having the proper protective gear that stands up to the most challenging chemical exposures. Solvent-related hazards can cause severe skin irritation, respiratory issues, and chemical burns, making PPE selection critical for worker safety. Choosing gloves, face shields, and eyewear specifically rated for chemical resistance can mean the difference between minor exposure and severe injury in solvent-heavy environments.

MCR Safety is dedicated to safeguarding workers who face solvent hazards daily by offering industry-leading chemical-resistant PPE and providing valuable insights into workplace safety practices. Our commitment doesn’t stop at supplying gloves and protective gear—we empower businesses with the knowledge and resources to build safer work environments. MCR Safety ensures workers are prepared, protected, and confident whether you need butyl rubber gloves, nitrile gloves, anti-fog face shields, or splash-resistant eyewear.

Click this image to leave us comments, questions, or any concerns.

For over 50 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's keeping workers informed about solvents on jobsites, or arming them with advanced PPE, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.