22 Jan 01/22/2019

Everything You Need to Know About The New ANSI ISEA 138 Impact Protection Standard

The U.S. Bureau of Labor Statistics concluded that in 2015, workers sustained 143,000 injuries to their hands. When you peel back the onion further, 76% of on-the-job hand injuries result from cuts and crushes. Yet, it’s only been within the last decade that PPE manufacturers have turned their attention to developing a more comprehensive range of gloves, including those designed with back-of-hand impact protection.

While there is a hand-protection standard in North America, ANSI/ISEA 105: 2016, American national standard for hand protection classification, addresses the cut, abrasion, tear, and puncture performance of gloves, not impact protection. The information below provides key insights into everything you need to know when it comes to the new back-of-hand standard for gloves.

Impact Safety Gloves

The bones and soft tissues located on the back of a worker’s hands are exposed to impact injuries, ranging from bumps and bruises to severe bone fractures.

- Struck by tongs or spinning chain

- Working around heavy pipes, cables, hoses, and ropes

- Everyday activities

- Being struck-by objects in motion, whether moving, swinging, flying, or falling

- Rig site clearing

- Heavy material handling and moving heavy loads

- Connections breaking free from high-pressure lines

- Improper use of tools that are loose and cracked, eventually breaking apart

- Working in close quarters, where pinch points are common

An oil and gas worker; who wears the Predator PD2903 gloves put it this way, “You need padding all around due to working around and holding iron that weighs anywhere from 500 to 1,000 pounds.” There is no better way of expressing the need for impact protection.

The New Guidelines

Oil and Gas workers face numerous workplace hazards and risks.

It has been challenging for companies to determine which impact gloves are best for their workers—which ones will keep workers’ hands safe while allowing them the full range of motion to get their jobs done. As a result, companies have begun focusing more on cost—a known quantity—and purchase gloves that are not always best suited to protect their workers.

Impact Work Gloves ANSI 138

ISEA is the leading association for personal protective equipment and technologies that enable people to work in hazardous environments.

Mandates from Impact Resistant Gloves Standards

- Defines an agreed-upon testing method for gloves’ impact protection

- Includes three clearly defined performance levels

- Specifies a pictogram mark for each of the levels of compliant gloves

- Requires that products be tested in a laboratory with a certificate of accreditation meeting the requirements ISO/IEC 17025:2017, General requirements for the competence of testing and calibration laboratories

ANSI 138 Performance Levels

.jpg?h=311.556&w=621.111&hash=1D7DA3B41501EF7108EF36DAD76488A2)

ANSI/ISEA 138 is used to “evaluate compliant gloves ‘for their capability to dissipate impact forces on the knuckles and fingers' and to classify them accordingly.” The testing that the gloves must undergo is rigorous, and the standard defines the testing requirements, equipment, and method to be used. It includes preparing samples and conditioning the gloves for specific test sites on the knuckles, fingers, and thumbs. The standard also requires that the sites be marked on the outside and backside of the glove.

Gloves are rated on an impact-protection scale from 1-3.

The two most critical performance areas

As with any standard measuring performance, crucial elements distinguish gloves with a higher number from lower numbers. Here are the two most essential elements for the impact standard:

- Assessment of the fingers and thumbs – finger and thumb impact performance is assessed at two distances from the fingertip. The above New Impact standard image shows an example of the two assessments.

- Knuckle protection – knuckles are located by having a test subject don the test glove, and then locate the exact knuckle locations while grasping a tube. There are some gloves where the knuckle bumper does not cover the wearer’s knuckles and, as a result, protection is compromised.

Specifications of ANSI/ISEA 138 impact standard

The resulting classification of each rating is as follows, with protection increasing as one move to the next performance level:

| Performance Level | Mean Transmitted Force |

|---|---|

| 1 | ≤ 9 kN |

| 2 | ≤ 6.5 kN |

| 3 | ≤ 4 kN |

As stated above, the higher performance level means there is better overall impact protection. However, when you examine the transmitted force, the lower number is better. Why? A lower recorded Peak Transmitted Force (PTF) means the glove's back-of-hand material absorbs more energy. Better material and protection equates to more energy absorbed, which equates to a higher-performing glove overall.

FF2930 – Impact Performance level 2

The FF2930 is our highest-rated impact glove.

Swinging chains are a constant concern for Oil and Gas workers.

D3O® Impact Technology Video

The FF2930 incorporates D3O® technology, which provides wearers with advanced protection. Examples include:

- Back-of-hand impact dissipation is up to 54% better, while the glove is 57% thinner.

- Impact dissipation on fingers is up to 46% better, while the glove is 37% thinner.

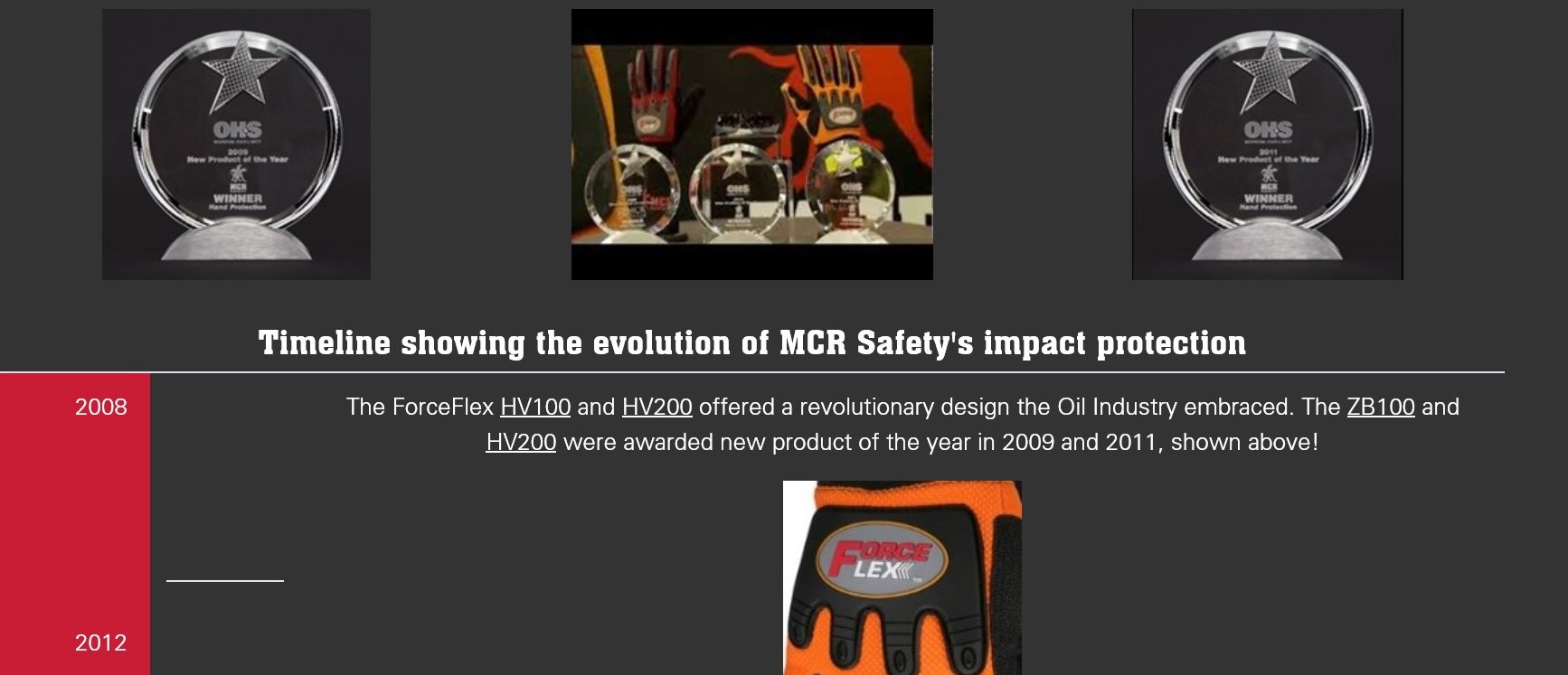

MCR Safety has come a long way over the past decade. Click the below image to check out our Impact Protection Resource page, highlighting the last decade of advancements in impact protection, along with the new back-of-hand protection standard.

Impact Protection Page

Impact Protection Selection Tool

On the Impact Protection Page, you can select specific impact gloves based on the impact performance level. For those only needing bump protection, the MC503 is perfect! However, if you need protection against high impact hazards, our tool will reveal the specific gloves tested for higher performance levels.

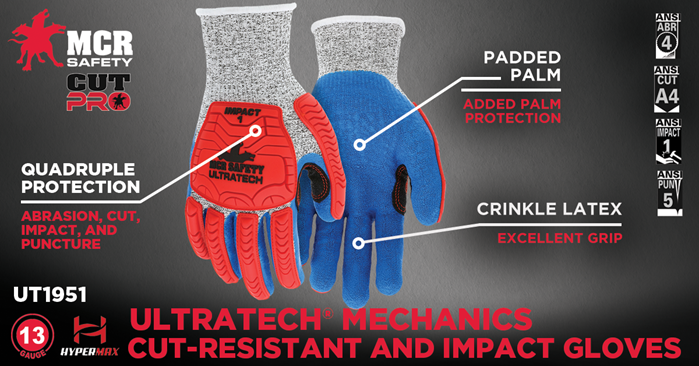

You can find all our impact protection gloves by visiting our dedicated online impact glove catalog. Here are some of the other impact gloves you'll see in our catalog.

Impact Absorption Work Gloves

The next chapter in back-of-hand protection is here! Industry standards for impact resistance will ensure back-of-hand performance measures are met and workers stay protected with the best gear.

MCR Safety's Oil and Gas industry web pages offer more insight into industry-specific hazards and oilfield impact gloves.

Click the above image to leave us comments, questions, or any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's wearing premium EVA rain boots while working on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

Safety Professional Handbook

Get industry knowledge on finding the right PPE for your job and understanding safety standards like OSHA. Stay Safe!

Eyewear Buying Guide

Each year, more than 2.5 million eye injuries occur. Protect yourself by finding the right eye protection for the job.

About the Author

Related Articles

Common Crush and Pinch Point Hazards

A common mistake when purchasing PPE is relying strictly on individual unit cost at the time of...

The Top Workplace Hazards for Oil and Gas Workers

If you work in the oil and gas industry, you know that the hazards you and your fellow workers...

Top 10 Most Popular Oil and Gas Gloves, Glasses, and Garments

We work hard, so that you can tool. Learn about our top 10 Most Popular Oil and Gas Gloves...Latest Articles