15 Jan 01/15/2019

The Top Workplace Hazards for Oil and Gas Workers

Sharp objects are everywhere across a refinery, meaning cut hazards are prevalent if proper cut gloves are not worn.

On our web pages devoted to the Oil and Gas Industry and sub-industries (Exploration Drilling and Production, Pipeline Transportation and Storage, Refining, Oilfield Equipment, and Services), we've identified nearly 40 categories of hazards that workers may face daily. We'd like to tell you about eight of the most common hazards across the entire oil and gas industry and let you know which of our PPE products can help keep you safe in your particular line of work.

Wearing the appropriate personal protective equipment (PPE) can mean the difference between remaining safe and sustaining a severe injury that could lead to death.

Chemicals and Other Liquids

Chemical burns are always a concern. Working around acids, additives, corrosives, solvents, and wastewater puts you in direct contact with toxic substances, such as citric and HCI acids, ammonia, and hydrogen fluoride. Below are some other common chemicals found in oil and gas:

- Benzene - is a crucial component of gasoline

- Methanol and Sodium Thiosulfate - are used as chemical stabilizers

- Hydrochloric acid - acidizes carbonate formations

- Sulfuric Acid - found during the oil refining process

- Toluene - found in the extraction and refinement of oil and gas

Check out the following oil field chemical industry PDF, which outlines most all chemicals used across the entire industry.

When encountering hydrogen sulfide, which occurs naturally in oil and gas, you will need chemical gloves, a face shield, and goggles when handling chemicals and opening pressurized systems. Also, it's important to note that numerous chemical environments involve hazardous gases in oil and gas industry. Even though MCR Safety doesn't carry respiratory protection, it's highly advised to conduct safety hazard assessments if gases are present.. Employers must provide respirators if workplaces have unsafe atmospheric conditions so they aren’t breathing in the chemicals.

A few of our products that you might want to consider if you work around chemicals:

Be sure to look at our glove-permeation guide, which allows you to search glove options by individual chemicals. It should be your starting point for identifying any chemical-resistant glove needs.

Click the above to check out our dedicated safety goggle online catalog.

Oil Impact

- Repairing equipment

- Moving tools

- Unloading materials

- Assembling and disassembling drilling pipes

- Working with heavy spinning chains,

- Lifting gear with chain hoists,

- Operating a sledgehammer

- Working around equipment and loads that swing or have motor-operated valves.

MU3634K holding a striking wrench offers Level 1 resistance

56% of all recordable Oil & Gas incidents result from workers being "struck by" and "caught between" objects. Hand and finger injuries are common in the oil and gas industry and can account for nearly 50 percent of incidents, though this number can climb as high as 80%! In 2015, the International Association of Drilling Contractors (IADC) reported the most significant number of injuries sustained by workers on land affected their hands and fingers, accounting for nearly 38% of all reported incidents.

On the water, those injuries reached nearly 45%. Three of every five on-site fatalities in the oil and gas extraction industry result from struck-by/ caught –in, or /caught-between hazards. The second most common cause of fatalities in the oil and gas industry was being struck by an object or piece of equipment. Twenty-six people died in such an incident.

Click the above image to check out our entire online impact glove catalog, ranging from impact level 1 to impact level 3, with most designed for pipelines and oilfields. The gloves below are ideal for oilfields, with the Sasquatch lineup being our heavy-duty style.

Why do we call the PD4906 the iconic Oil & Gas glove? First, it's an impact-resistant glove with ANSI level 1 TPR, which contrasts against the glove's material. It's perfect for keeping rig crews noticed. Second, it features a rough PVC palm, ideal for picking up slippery objects. Third, the neoprene cuff extends past the wrist, keeping objects from entering. Lastly, it has reflective stripes on both sides of the cuff, increasing visibility.

Are you looking for a leather glove that repels oily substances? The 36336 is equipped with oil block technology to provide users with excellent repellant properties. Combine that with impact resistance, abrasion resistance, and double-stitching.

Field test results confirm this is one of the longest-lasting gloves, up to 4X longer than standard leather.

Cotton gloves are going nowhere anytime soon. Not only did we release the UT1901, but we also introduced the UT1902. Look at how wonderfully the yellow impact level TPR contrasts against the orange cotton.

Welding Hazard and Safety Concerns

The metal components you’re welding may have jagged and sharp edges, and you’re working with high heat from a flame or electricity. Burns and shocks are common risks. Radiation exposure is also possible, along with respiratory-related illnesses and conditions. Welding is a leading cause of worker exposure to hexavalent chromium [Cr(VI)], one of the valence states of chromium, a known carcinogen that also can affect the respiratory system, kidneys, liver, skin, and eyes.

Cutting any objects raises the risk of cutting your hands with the equipment you’re using or getting cut by the material you’re cutting. According to 2014 statistics, hand and finger injuries comprised 43% of all recordable incidents on drilling rigs, a slight increase over 2013 (41%) and 2012 (40%).

.png?h=421&w=773.667&hash=5D27A3E7422F230D1ABD711158B91944)

For welding, we offer a wide assortment of glove that are perfect for different applications. We also carry leather welding gear, as shown below.

MCR Safety manufactures a full line of welding clothing designed for dangerous elements in welding oil and gas environments. Unfortunately, synthetic materials like polyester will melt when extreme heat is present and potentially ignite. We've showcased in this image some of our top-selling leather welders, which will not ignite

For more information on this subject, we encourage you to check out our article titled An Overview of Welding in Oil and Gas, from the Pipelines to Steel Platforms, and the PPE welders require

Dust

Dust is virtually inescapable, especially if you are doing heavy construction work, operating or performing machine maintenance, or loading and unloading material.

Silica is the primary component of sand and rock, meaning silica dust exposure is common during hydraulic fracturing operations. Hydraulic Fracturing involves pumping large volumes of water and sand into rock, allowing oil and gas to flow into a designated well. The process involves transporting silica sand into and through sand movers, releasing dust into the air.

Worker delivering sand from the sand mover

OSHA has classified crystalline silica as a lung carcinogen. Breathing it in can cause silicosis, which can be disabling or fatal. Once in the lungs, crystalline silica causes scar tissue development and build-up, inhibiting the lungs’ ability to function correctly. Conveyor sand, operating engines, and motors are all areas where getting dust in your eyes is an irritating concern.

NIOSH lists seven primary sources of silica dust exposure:

- Dust ejected from thief hatches (access ports) on top of the sand movers during refilling operations while the machines are running (hot loading); Dust ejected and pulsed through open side fill ports on the sand movers during refilling operations;

- Dust generated by on-site vehicle traffic;

- Dust released from the transfer belt under the sand movers;

- Dust created as sand drops into, or is agitated in, the blender hopper and on transfer belts;

- Dust released from operations of transfer belts between the sand mover and the blender; and

- Dust released from the top of the end of the sand transfer belt (dragon’s tail) on sand movers.

RP310PF seals a workers eyes from debris and dust

Fire and Explosion

- The drilling process hits formations or zones of hydrocarbons (oils and gases);

- Accessing or extracting the oil and gases;

- Servicing active wells of any kind;

- Stimulating, plugging, or capping inactive wells;

- The well has been drilled, completed, and placed into operation, or when

- The well fluids are brought to the surface and separated, stored, gauged, or otherwise prepared for product delivery

Triple-Vented fire resistant clothing oil and gas

Triple-vented FR clothing is the safest product for those concerned with flash fires.

Check out our FR clothing web page for all styles offered.

Getting Gas and Oil in Eyes

Are you working around oil or with compressed air? How about performing a safety inspection? Impaired vision can occur from numerous sources in this industry, especially when gas and oil are everywhere. Eye protection will help keep your eyes safe. There is no shortage of activities in the oil and gas industry where a worker’s eyes need to be protected. Material coming off drilling pipes, splashing chemicals, flying debris, and sparks are all concerns every oil and gas worker faces. Working outdoors in high winds further increases the likelihood of eye injury.

OSHA requires that workers wear eye and face protection when exposed to or at risk of exposure to flying objects, molten metal, liquid chemicals, acids or caustic liquids, chemical gases or vapors, or potentially injurious light radiation.

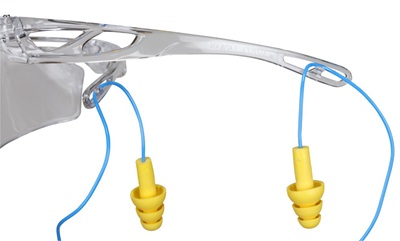

CL4 safety glasses allow earplugs to act as lanyards with earplug retaining technology.

.png?h=435.333&w=811&hash=E1327F201E3DA6B2AED4198980F407E1)

DM1328BZ worn at an oil and gas refinery

Numerous lens types are required for oil field safety glasses. Click the image above to check out our online safety glass and goggle catalog.

Oil Resistant Steel Toe Boots

Countless dropped objects can fall on a worker’s hands and feet during the maintenance of refineries or when extracting oil and gas. Examples include:

- Perform any repair and maintenance work

- Moving materials

- Operating a valve

- Servicing wells,

- Cleaning oil spills

The above are only a few tasks to consider; there are numerous others. You will also need steel-toed boots when working around water or other liquids, chemical hazards, and dropped impact hazards. Essentially, it means you'll need boots across any part of oil and gas operations.

Oil Field Steel Toe Work Boots

Physical Hazards

Our 3601K gloves protect oil and gas workers from numerous sharp objects

Physical hazards in oil and gas industry are always concerning, no more so than those that can lacerate a person's body. Cuts and lacerations comprise 7% of all oil and gas injury claims. If you are clearing a site, doing construction, or using any hand tools, you are more likely to be injured by a sharp object. Whether you’re sanding, grinding materials, cutting pipe, or mounting motors and pipe with metal shims, you’ll need to protect your hands from cuts and lacerations.

According to a report in Industrial Safety and Hygiene News, 70% of workers who injure their hands aren’t wearing gloves. The remainder is wearing gloves inappropriate for the task, damaged, or otherwise inadequate.

.png?h=441.333&w=942.667&hash=EFE7C405D567D588371EDDA3F26A0BC6)

We have many pairs of gloves that offer superior cut protection. Notice how we carry a solution across all cut performance levels to consider if you’re especially concerned about handling sharp objects. Check out all our cut-resistance products and ANSI scores here.

Hazards Idenfification

Occupational health hazards associated with oil and gas extraction activities are endless. So, having increased knowledge is always helpful. Below are some of the numberous links we know are beneficial in assisting safety manager in this industry.

- Extraction Hazards

- Upstream hazards in oil and gas industry pdf

- Safety Management in Oil and Gas

- NIOSH Health and Safety Risks

- OSHA Powerpoint on Guidelines

Common Questions

- Is oil a hazardous material?

The United States Environmental Protection Agency (EPA) details oil housekeeping requirements in Title 40 of the Code of Federal Regulations (CFR) part 279. However, you'll want to review your specific state's regulations, as they may be stricter.

- What is the main risk and hazard in oil and gas?

Explosions and fires are always one of the main concerns safety managers face daily, making it the leading risk workers face.

Hazards and Demands of Oil and Gas

Click the below image to leave us comments, questions, or any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's erecting a scaffold, carrying heavy materials, or working at a construction site, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Click the above image to be taken directly to our PPE online catalog.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

MCR Safety's Oil and Gas industry web pages offer a lot more insight into industry specific hazards and PPE

Eyewear Buying Guide

Each year, more than 2.5 million eye injuries occur. Protect yourself by finding the right eye protection for the job.

MCR Safety Impact Glove Protection Buying Guide

About the Author

Related Articles

Top 10 Most Popular Oil and Gas Gloves, Glasses, and Garments

We work hard, so that you can tool. Learn about our top 10 Most Popular Oil and Gas Gloves...

An Overview of Welding in Oil and Gas, from the Pipelines to Steel Platforms, and the PPE welders require

Did you know that 10% of all U.S. eye injuries happen in welding? It’s a dangerous job,...

OIl Rig Explosions and Flame Resistant Clothing Dangers

Industries take great care in preventing fires and explosions because they expose workers to...Latest Articles

.png?h=377.333&w=739.667&hash=2191BD118FBDA47EC3B8FF761F2F908D)