23 May 05/23/2019

Top ANSI Rated Puncture Resistant Gloves

Hand injuries are expensive. The combined costs of medical bills, workers compensation, and lost productivity quickly add up - and that’s not even counting the possibility of lingering or even permanent disability. For employers and employees alike, the best possible insurance against the damaging effects of hand injuries is the proper use of effective PPE. In a word: gloves.

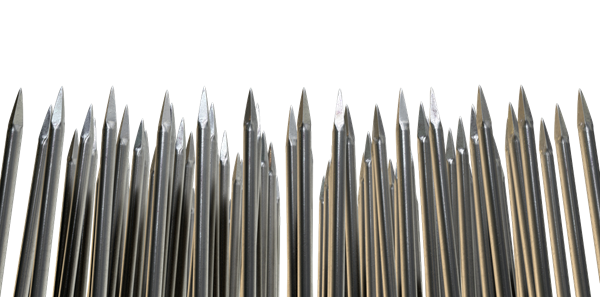

Sharp pointed metal is a definite concern for many workers.

92743BP achieves puncture level 5 resistance.

Not all gloves are created equal, and no glove offers protection against all types of injury. A glove that tries to provide the best performance for every feature all at once, heat, abrasion, cutting, impact, and puncture resistance, will be too stiff and unwieldy to do any work. The majority of workers don’t need that much protection anyway. Plus, companies would wind up paying high costs for protection their workers didn’t need. In a time of rising tariffs, this is the last thing any company wants to do.

In many workplace applications, the most important consideration for protective gloves is puncture resistance. Below, we highlight everything you need to know regarding puncture protection.

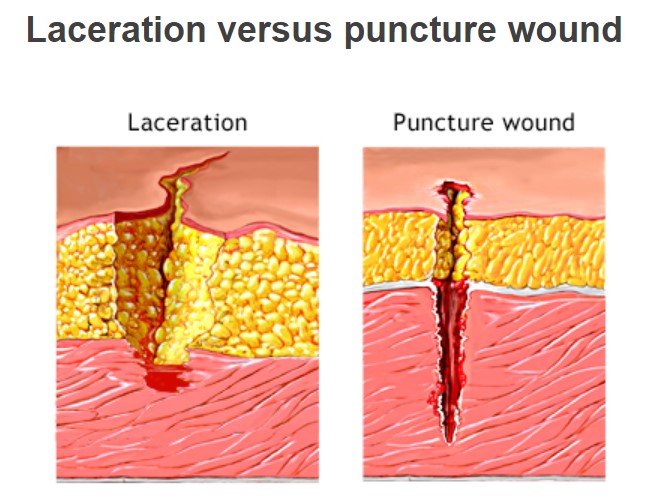

What Is a Puncture Wound?

A puncture wound is a forceful injury caused by a sharp, pointed object that penetrates the skin. Puncture wounds tend to be deeper and narrower than cuts or scrapes. However, when you think of how most cut injuries and lacerations occur, they often start with a puncture.

One thing to keep in mind as we continue is that no glove is completely puncture-proof, as any material can be penetrated given sufficient force.

Even though puncture proof doesn’t exist, our ITC lab provides some powerful scientific data to help you choose the best puncture-resistant gloves. So, while puncture resistance doesn’t make anyone impervious to harm, it can significantly reduce the number of workplace injuries.

ANSI Puncture Testing

When it comes to PPE performance levels, especially puncture resistance, we know users want gloves that can be trusted to perform. So, we leave nothing to chance when it comes to puncture protection.

ITC Lab

Our Innovations Technology Center (ITC Lab) has been in operation since 2010, testing PPE for cut, abrasion, heat, puncture, impact, and tear resistance. In July of 2016, our commitment to excellence led to the ITC becoming one of the first North American testing labs to receive ISO/IEC 17025 accreditation for hand protection. This international standard requires labs to demonstrate a high degree of accuracy and consistency in testing protective equipment.

Puncture Testing Machine

Our lab tests gloves to ANSI/ISEA 105-16 for puncture resistance, while utilizing Clause 6.4 of EN388:2003 as the test method. The Instron machine, shown in the image above, determines the amount of force exerted by a steel stylus to puncture a glove palm. The stylus is pushed through the material at a fixed speed, providing a measurement to show the newtons of force required to pierce through the material.

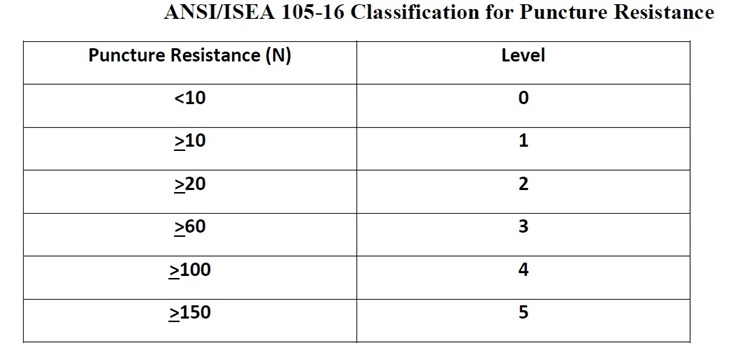

Performance levels are awarded in accordance with an average number assigned to 12 test results. Here are the newton levels a glove must withstand to be labeled with a specific puncture resistance level:

Our new 92735N outperforms the level 5 resistance. The force required to puncture through the material was 179.60 newtons, an average of 12 samples tested.

The chart above lists the puncture resistance tests, which are an excellent gauge for how resistant the fiber materials are in a particular set of gloves. It also helps determine how a glove will respond in an industrial setting when foreign objects can potentially penetrate a glove.

Hypodermic Needle Resistant vs. Puncture Resistant

Puncture resistance is the ability to withstand penetration. However, not all puncture protection is the same, as there are delicate objects that puncture through gloves. With this in mind, it’s dangerous to assume that a glove with a high puncture level is also rated for needle resistance; it may not be.

Hypodermic Needle protection deals with thinner gauged hazards.

The European EN388 6.4 puncture test (the test method mentioned above) uses a 1mm stylus, which is utterly inadequate to test resistance to needles, which may be a tenth of that diameter or smaller.

In recognition of this shortcoming, ANSI introduced the ASTM F2878-10 puncture test in 2016. This test uses a 25-gauge probe to better simulate a hypodermic needle stick. For both tests, resistance is rated on a scale of 0 to 5 based on average newtons of force applied to 12 testing samples at the instant of failure. The EN388/ANSI 105 test requires the material to resist more than 150 newtons to achieve a 5 rating. The F2878-10 test only requires 10 newtons of resistance for a 5 rating, which is a good indication of how challenging it is to make an effective needle-resistant glove.

ML300A, MCR Safety’s Needle Stick Glove

Bloodborne pathogen exposure is a significant concern today, with the increased use of drugs. When there is a strong potential for coming into contact with harmful substances and syringes are involved, you want a glove that has been tested against the F2878-10 testing method.

The Importance of Puncture Resistant Gloves

44% of hand injuries - 60,000 injuries in 2017 - are due to cuts, lacerations, and punctures. Puncture injuries are likely to occur around objects like nails and glass, along with many other sources we outline below.

While puncture wounds may not bleed as much as other types of injury, they are more prone to infection. Bacteria and debris can be forced deep into the wound, which may close quickly and form an ideal environment for infection to grow.

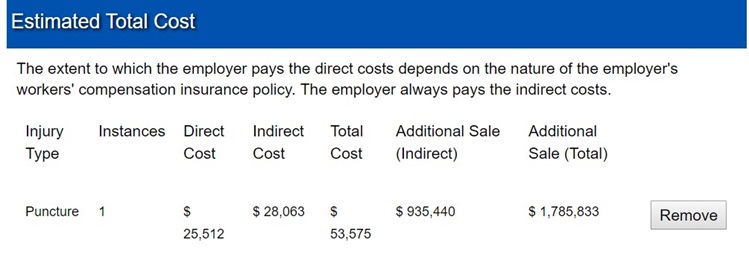

If you think a bacterial infection sounds awful, the numbers help prove it’s not something you want to experience. OSHA’s estimated direct cost of puncture injuries comes in at $25,512 (see chart below).

For workers with potential exposure to hypodermic needles, puncture resistance is even more vital. A needle puncture wound can infect the victim with residual narcotics or bloodborne pathogens like hepatitis or HIV.

Yes, the advanced materials required to make this type of glove cost more. However, it’s a minimal expense in comparison to the potential total costs.

Puncture Resistant Glove Filtering

Finding the right glove is necessary, and there's no better tool than the MCR Safety Online Catalog. Our easy-to-use filter makes it simple to hone in on precisely the features you need.

Just select the puncture resistance required for your given application, and we highlight the appropriate gloves, all with just a couple of clicks.

Our Best Options

Filtering the best gloves gives you all our options all in one place. However, we know many of you want to see your options, right here, right now. Let's get started highlighting some gloves!

Level 5 Gloves

- 92735N – Provides users with A9 cut protection and level 5 puncture protection.

92375N is a bonafide heavy hitter, with A9 cut and puncture 5 protection.

- 92743BP: A seamless shell and black bi-polymer palm and fingers make these gloves comfortable and easy to wear.

- 9687: The durability and breathability of Kevlar, with the sure grip of latex rubber coating on fingers and palm.

- 1400K: Leather, lined with Kevlar and a reinforced cuff, provides superior all-around protection.

Level 4 Gloves

- UT2953: Padded palm for impact and vibration reduction with excellent back-of-hand protection.

UT2953 handling steel, with back-of-hand, cut, and puncture protection.

- 9178LO: Lightweight thermal protection with superior dexterity and comfort. Touch-screen friendly!

- ML300A: High visibility with Alycore cut and needle stick protection.

Level 3 Gloves

- MG9645: PVC/Nitrile bi-polymer with a 12” gauntlet cuff.

- 9178NFO: Hi-Vis Orange for safety awareness, made with DuPont™ Kevlar®, Nitrile Foam

9178NFO, made with Orange DuPont™ Kevlar® has been a top seller for many years now!

Triple Protection: Cut, Puncture, and Impact Resistant

PD46312 and PD4900 offer wearers triple protection with A9 Cut-Resistance, Puncture 5 protection, and impact level 1 protection.

Both gloves feature an inner DuPont™ Kevlar® liner that achieves the highest achievable ANSI cut and puncture resistant scores. Wearing these gloves protects the user's knuckles and back of the hand with premium materials ensuring the highest level of protection.

Industries

So, who needs puncture resistance? Almost anyone who works with their hands would probably benefit from at least some level of cut and puncture protection. In some fields, the level of exposure to needles, wood splinters, metal fragments, or other puncture risks is high and the need for PPE is evident. Here are the industries that definitely need to consider wearing puncture protection due to the number of puncture injuries that occurred in 2017:

- Construction – 2,230 injuries

- Manufacturing – 2,140 injuries

- Waste Services – 1,290 injuries (Needle risks are a definite concern)

- Ambulatory Health Care – 1,100 injuries

- Services to Building – 960 injuries

- Agriculture, Forestry, Fishing – 590 injuries

- Transportation and Warehousing – 590 injuries

- Landscaping – 540 injuries

- Framing Contractors – 530 injuries

- Wood Product Manufacturing – 470 injuries

Other industries

- Food Manufacturing – processing

- Law Enforcement Personnel - police, federal agents, and jail and prison workers

- Pulp and Paper – machine setters

Top Occupations Requiring Puncture Protection

Construction Framing

The above industries are definitely where you will find puncture protection being worn. Here are the top two occupations that absolutely need to be on the lookout for the best puncture protection offered:

Recycling and Reclamation Workers – prepare and sort material for recycling. Removing hazardous substances requires excellent puncture protection, and sometimes needle protection due to the unknown nature of what is handled.

Paper Goods Machine Operators – operate machines that convert paper sheets into products. Installing attachments to machines for cutting requires excellent cut and puncture protection.

Other occupations and their puncture injury rates in 2017

- Building and Grounds Cleaning Workers – 1,160 puncture injuries

- Carpenters – 1,040 puncture injuries

- Material Moving Workers – 770 puncture injuries

- Food Preparation Workers – 680 puncture injuries

- Framing Contractors - 530 puncture injuries

In addition to the above industries, we receive regular inquires from the following customers requesting cut and puncture-resistant gloves:

- Gardening customers - We have an entire article written on gardening gloves.

- Machine Shop workers

- EMS

Applications and Events

Here are some of the activities the above occupations perform every day at work:

- Animal handling – dogs, birds, etc.

- Blade handling

- Cardboard handling

- Cutting meat and meatpacking

- Contact with objects and equipment – 10,220 events occurred in 2017, #1 cause of injuries

- Handling fine sharp objects

- Gardening

- Glass handling

- Handling barbed wire and rebar

- Knife handling

- Logging

- Metal fabrication - metal stamping and sheet metal handlers

- Moving materials

- Packaging

- Parts assembly

- Prison Weapons

- Sawmill work

- Scrap handling

- Sharps handling – needles, scalpels, and syringes

- Sharp metal handling

- Swinging object held (oil and gas) - 1,570 events occurred in 2017

- Waste handling

Sources of Injuries

Construction Materials

The U.S. Bureau of Labor Statistics (BLS) reports the following as some of the main sources in 2017 where puncture wounds occurred:

- Animals – 4,490 injuries

- Parts and materials – 4,480 injuries

- Fasteners, connectors, ropes, and ties – 3,850 injuries

- Nails, brads, tacks, nuts, bolts, and washers – 2,870 injuries

- Hand tools – 1,440 injuries

- Scrap, waste, debris – 1,260 injuries

- Needles, syringes – 1,180 injuries

- Chips, particles, splinters – 1,170 injuries

- Metal chips and particles – 540 injuries

- Knives – 500 injuries

- Machinery – 480 injuries

- Screws – 430 injuries

Other sources of concern: glass, barbed wire, and sharp tools.

Common Questions

How puncture resistant are a leather glove?

- Leather is tough, achieving medium level puncture scores on its own. However, when it comes to cut-resistant, it's weak. Our new PD46312 mentioned above achieves both A9 cut and puncture 5 resistance, the highest rating in both categories.

Are nitrile gloves puncture resistant?

- A nitrile polymer is highly puncture resistant, much higher than latex. However, within the context of ANSI puncture scores, it will need additional material to score high enough to provide the protection most users will require around actual puncture hazards. Don't purchase a nitrile coated glove for puncture protection without first checking the ANSI score.

Where to buy puncture resistant gloves?

- Numerous nationwide industrial distributors regularly stock the MCR Safety puncture-resistant gloves shown above. Request a quote below with your information, and we will be in touch to provide local distributor information. You can also enter the part number into Google, and you will most likely find distributors selling the glove online.

A9 Kevlar: Innovative Material for Premium Protection

Kevlar® is used in the new PD4900 and PD43612

7 out of 10 hand injuries are caused by workers not wearing gloves. The main reason they're not wearing gloves is that they find them challenging to wear. Sometimes the problem is simply a matter of fit, but often it is due to not having the proper glove for the job. We hope you don't take chances and choose to wear appropriate protection when it comes to puncture protection. Our new PD4900 and PD43612 are two of the lightest weight A9 puncture-resistant gloves found on the market today. We think you will enjoy wearing either option!

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it’s on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It’s all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

Metal Fabrication Application Matrix

Find the appropriate PPE for specific hazards with a simple easy to follow guide.

Eyewear Buying Guide

Each year, more than 2.5 million eye injuries occur. Protect yourself by finding the right eye protection for the job.

About the Author

Latest Articles