16 Jun 06/16/2020

OSHA and Safety Glasses

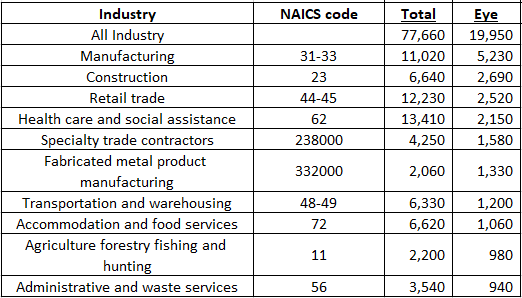

After worksite inspections were completed by the Occupational Safety and Health Administration (OSHA) in 2018, they found that one of the top 10 most frequently cited violations is 29 CFR 1926.102—the eye and face personal protection safety and health regulation for the construction industry. And, if there is one industry where workers need to be wearing safety glasses, it is the construction industry. According to the Bureau of Labor Statistics (BLS), in 2019, the construction industry had the second-highest eye injury rate, accounting for over 13% of all on the job injuries.

According to the BLS, the above shows the top industries with eye injuries

Not only that, but eye injuries alone cost companies more than $300 million per year in lost production time, medical expenses, and worker compensation.

OSHA and the BLS publish this information to alert employers of potential concerns and dangers present. This data allows employers to take steps to find and fix the hazards that can cause citations in the first place. Even more so, it helps prevent people from getting hurt. Unfortunately, many risks, such as exposure to heat, dust, and chemicals, are characteristics of the jobs people perform.

As a result of these potential hazards, OSHA requires employers to provide eye and face protection for all employees. Both employers and workers need to be responsible for the prevention of thousands of work-related eye injuries by staying informed about the proper selection and use of eye and face protection.Below, we highlight all you need to know about safety glasses and eye protection.

OSHA Regulations

OSHA breaks down applicable standards into several categories that ensure workers are protected in the workplace. Here is a quick snapshot of each one:

- General requirements: 29 CFR 1910.132 – requires employers to provide, at no cost to employees, appropriate PPE, including safety glasses, for protecting the body from hazards.

- General industry: 29 CFR 1910.133 – employers shall guarantee that each affected employee uses proper eye or face protection when subjected to eye or face hazards from:

- flying particles;

- molten metal;

- liquid chemicals, acids, or caustic liquids;

- chemical gases or vapors, or potentially injurious light radiation.

- Construction industry: 29 CFR 1926.102 – specific regulations are set for construction-based environments. As we highlighted above, the construction industry involves dangerous activities, reflected in the number of eye injuries.

All eye and face PPE must meet minimum requirements to provide adequate protection, such as durability, easy cleaning and disinfecting, a snug, comfortable fit, and safe, effective design and construction. Also, all PPE must be distinctly marked to facilitate identification only of the manufacturer.

OSHA's eTool

We've highlighted OSHA's regulations above. Now, let's cover some additional requirements outlined by OSHA. The Eye and Face Protection eTool is a web-based training tool that provides compliance information to help employers and workers in selecting the proper eye and face protective equipment as it applies to the potential eye and face hazards in different working conditions.

29 CFR 1910.132(d) says an employer must first assess the workplace for hazards that require eye and face protection. 29 CFR 1910 Subpart I App B explains that the hazard assessment should determine the risk of exposure to eye and face dangers during normal operations and emergencies. Employers should be prepared to protect workers against the highest level of each hazard.

Check out the frequently asked questions on OSHA's eye and face protection eTool page for more information.

Workplace Hazards Requiring Eye and Face Protection

The four main hazards most likely to cause eye injury if workers are not appropriately protected are heat, chemicals, dust, and impact. We cover all four below, along with welding eye hazards, too. After we highlight each hazard, we've provided quick links to MCR Safety's eye protection.

Chemicals

Serious and irreversible damage can occur when chemical substances make direct contact with the eyes in the form of splash, mists, vapors, or fumes. Many times, injuries happen when handling acids and chemicals, degreasing, and plating.

When working with or around chemicals, you must know the location of emergency eyewash stations and how to access them with restricted vision.

OSHA PPE guidance for chemical hazards:

Chemical eye injuries often result from an ill-fitting or inappropriate choice of PPE, allowing a chemical substance to enter from around or under the protective eye equipment.

Safety goggles shield the eyes from liquid or chemical splash, irritating mists, vapors, and fumes, while face shields protect the entire face against exposure to chemical hazards.

Dust

Working in a dusty environment such as buffing, woodworking, or construction sites can cause eye injuries and present additional hazards to contact lens wearers. Safety goggles and lined safety glasses are the only useful type of eye protection from nuisance dust because they create a protective seal around the eyes.

OSHA PPE guidance for dust hazards:

Safety goggles protect the eyes against a variety of airborne particles and harmful dust.

Heat

Burns to eyes and facial tissue is the primary concern when working with heat hazards. Heat injuries may occur when workers are exposed to high temperatures, splashes of molten metal, or hot sparks. A worker must protect their eyes from numerous workplace operations that involve heat: pouring, casting, hot dipping, furnace operations, and other similar activities.

Working with heat hazards requires eye protection such as goggles or safety spectacles with special-purpose lenses and side shields. However, many heat hazard exposures require the use of a face shield in addition to safety spectacles or goggles. When selecting personal protective equipment, consider the source and intensity of the heat and the type of splashes that may occur in the workplace

OSHA PPE guidance for heat hazards:

Safety glasses and safety goggles shield the eyes from a variety of heat hazards, while face shields protect the entire face from many heat hazards.

Impact

Serious eye injuries such as punctures, abrasions, and contusions can result from flying objects like large chips, fragments, particles, sparks, sand, and dirt, or falling objects (which can be smaller than a pinhead) striking the eye.

Many everyday workplaces can create this type of hazardous environment with routine activities. Here are some: chipping, grinding, machining, masonry work, woodworking, sawing, drilling, chiseling, powered fastening, riveting, and sanding. The injuries sustained from an airborne particle hitting one's eye can be permanent, which means wearing safety glasses is an absolute must.

OSHA PPE guidance for impact hazards:

Safety glasses shield the eyes from a variety of impact hazards. Safety goggles shield the eyes against flying fragments, objects, large chips, and particles. Face shields protect the entire face against exposure to impact hazards.

Cutting Metal and Welding Eye Hazards

Welding, cutting, soldering, and brazing protection are especially important. The intensity of visible light and radiant energy produced by welding operations vary depending on the task, the electrode size, and the arc current. Eyes must be protected from burns caused by infrared or other intense radiant energy from flying sparks, metal spatter, and slag chips.

Only filter lenses with the appropriate shade number will protect against optical radiation. Filter lenses must coincide with specific radiant energy exposure. Welding helmets shield the eyes and face from optical radiation, heat, and impact.

OSHA PPE recommendations for welding and cutting hazards:

We highlight all our cutting glasses and welding filter shaded glasses on our Welding Protection page. You will also find some brand-new welding glove options when you're there, too!

MCR Safety's Eye Protection Quick Links

MCR Safety Glasses

MCR Safety Goggles

MCR Safety Face Shields

Welding Eyewear

MCR Safety's online eyewear catalog

MCR Safety's digital eyewear buying guide

ANSI Z87.1: OSHA-Approved Safety Glasses

On every pair of safety glasses, MCR Safety manufactures, you will see the marking "Z87+." We put this marking on our safety glasses to validate that the eye protection has been tested to the ANSI Z87.1 standard. The test for this standard involves shooting a steel ball traveling over 100 mph at the glasses' lens. Safety goggles are measured at 170 mph.

OSHA uses ANSI standards as guidance for determining criteria and requirements for the use of proper PPE. We've provided multiple links above to the different types of eye protection MCR Safety offers.

Here are some more commonly requested safety glasses:

- Anti-fog safety glasses – In a 2013 eyewear survey MCR Safety conducted with end-users, 60% of all participants surveyed listed anti-fogging as the #1 most crucial buying decision when selecting safety glasses. We know what our customers need, and we've built online resources to help. Check out our line-up of anti-fog safety glasses on our website.

- BearKat® safety glasses – The BearKat® BK1 name, look, and cost-effectiveness have become synonymous with the very term "safety glass." It's our top-selling safety glass worldwide.

- Bifocal safety glasses – Safety glasses with readers, also referred to as magnifiers, are essential for those who need a little extra magnification.

- UV-AF safety glasses – MCR Safety is the first company to offer safety glasses that have been UV cured, improving both anti-fog performance and durability. The anti-fog technology, shortened to UV-AF, describes the very essence of the coating itself. It provides users with an anti-fog coating that costs the same as standard anti-fog, yet is 3X more potent at reducing fogged lenses!

- Polarized safety glasses – Polarized styles assist workers with glare, often during bright conditions, wet conditions, and snowy conditions. Our polarized lenses ensure that workers stay safe, perform their best at work, and avoid those dreaded headaches!

OSHA Z87-Compliant Transition Safety Glasses

Photochromic lenses in safety glasses allow workers to transition from an indoor work environment to a brightly lit outdoor job site wearing the same glasses because the lenses stay clear (or nearly clear) indoors and darken automatically when exposed to sunlight.

In 2019, MCR Safety developed our first photochromic safety glasses, one of the latest innovative styles we introduced. The advantages to our transition safety glasses include:

- Automatic adaption to changes in light conditions.

- Comfortable all-day vision.

- The ability to wear indoors and outdoors without switching between two pairs of glasses.

- 100% protection against harmful UVA, UVB, and UVC rays.

Common Questions

How to tell if safety glasses are OSHA approved?

- All OSHA-approved safety glasses must have markings specified by the American National Standards Institute's ANSI Z87. 1-2010 standard on both the lenses and the frame of the eyewear piece. If the lenses are Impact Rated, they also should have the manufacturer's mark, followed by a "+" sign.

What do OSHA regulations for safety glasses say?

- 29 CFR 1910.132 requires employers to provide, at no cost to employees, appropriate PPE, which includes safety glasses, for protecting the body from hazards.

Does OSHA require gloves and safety glasses when handling alcohol?

- Yes, whenever hazards can't be removed by engineering or administrative controls, chemical PPE is essential. Also,going back to OSHA 29 CFR 1910.133, any time risks are present when workers are subjected to perform their job duties, OSHA requires PPE to be worn.

Where can I buy OSHA-approved safety glasses?

- We can help you find a distributor of MCR Safety glasses, or you can expedite receiving a product on our Buy & Try site. After your purchase, we can provide a local distributor with your information at a later time.

Who has OSHA Z87-compliant transition safety glasses for sale?

- We highlight our photochromic styles earlier in this blog. As in the previous question, we can assist you in locating a distributor in your area who stocks these glasses.

Are tinted safety glasses OSHA approved?

- Yes, if they are Z87 safety glasses and clearly marked as such.

What is the minimum OSHA recommended shade for safety glasses used while brazing?

- Check out OSHA's PPE publication, OSHA 3151-12R 2004, for all safety glasses requirements when brazing.

Are sunglasses just as protective as safety glasses?

- You need to make sure your sunglasses are labeled with the Z87 mark. Many of our safety glasses have a sunglass-inspired look and style, such as our polarized safety glasses—but they can also stop a steel ball going 102mph at 150 feet per second, which your average sunglasses cannot!

MCR Safety Offers the Best Eye Protection

Don't settle for just any protective eyewear. Choose eye and face protection that you'll love to wear. MCR Safety designs the most stylish PPE eyewear using industry-leading advanced technology. With an extensive choice of frame and lens colors, you will find the right eye protection for any application so you can stay safe and look good while doing it.

We welcome any comments, feedback or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at (800) 955-6887.

About the Author

Latest Articles