Every construction site requires ample resources to function correctly, including resources for labor and material. Machines and equipment move resources in and around construction projects and perform some specific tasks humans can't execute efficiently or at all.

Machine operators and maintenance workers must keep themselves protected around construction equipment.

Construction equipment serves various functions and comes in all shapes and sizes, from small ditch-digging devices to gigantic hauling trucks.

Some of the biggest machines ever to operate on land have been built to accommodate the construction industry's needs. However, it has not always been that way. When the Egyptian Pyramids and China's Great Wall were built, only hand labor was available. Workers moved the earth and performed their roles limited by the physical abilities they possessed. Today, machine power boosts production to heights only previously dreamed of by workers.

This article will cover some of the significant types of equipment used by today's construction professionals, identify some of the top equipment companies, and explore how construction machines are purchased. We also examine why safety is an important topic, especially around construction machines and equipment.

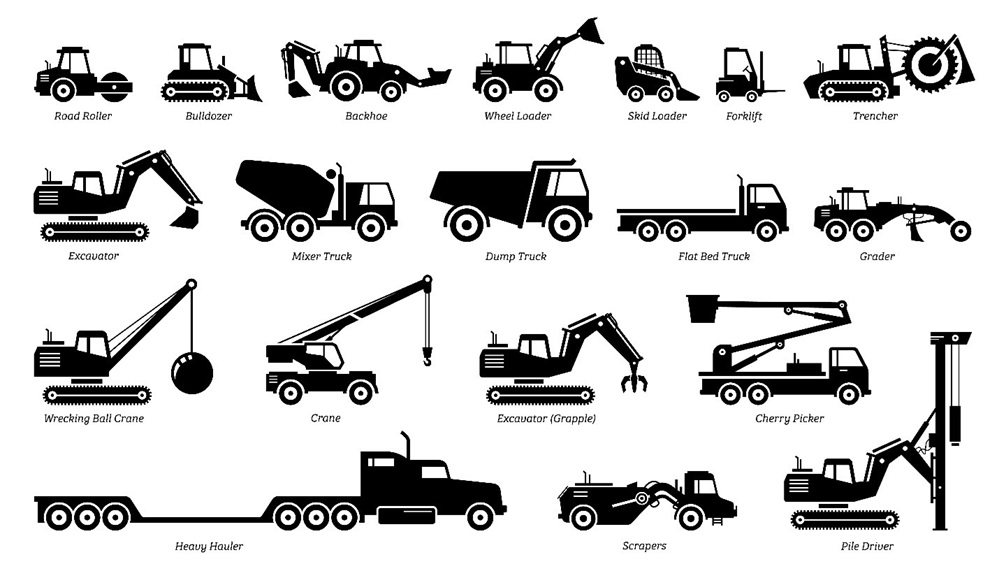

Equipment Names and Definitions

What counts as construction equipment? From a legal perspective, construction equipment includes all appliances and equipment used in the construction process. Construction professionals mainly look at equipment as the general term for describing the machines used on job sites, devices such as backhoes, dump trucks, and graders. These apparatuses perform all kinds of functions, from ripping and tearing up the ground to hauling materials to different locations.

Today's construction machines are divided into two core categories: earthmoving and material handling. Both types of machines are used across the entire industry, especially during heavy construction. Below, we take a closer look at what equipment rolls up under each category.

However, before we sort machines into categories, let's first define the most common ones found operating at construction sites.

Types of Equipment

Understanding the common types of equipment used in the construction industry can help everyone better understand what activity occurs. From a safety perspective, knowing what activity is taking place on a job site makes workers better prepared to notice potential hazards that may arise and consider the precautions they need to take to protect themselves.

Here is a rundown of some of the different types of construction equipment common on a job site:

- Backhoes – This type of hydraulic excavator is equipped with an attached hinged boom, featuring a bucket that it drags toward itself to move all kinds of natural and artificial materials. The end of the bucket has movable jaws that can grab and hold material.

Backhoe

- Bulldozers – These workhorses utilize a wide horizontal metal blade on the front that moves and pushes debris, dirt, earth, snow, ice, rubble, sand, or other materials. Instead of tires, bulldozers are situated on moving tracks.

Bulldozer

- Cherry Pickers – Featuring a hydraulic crane with a raised platform at the end of the boom, these machines help raise and lower people to specific heights.

Cherry Picker

- Compactors – A compactor's heavy drum helps compact material so that it is fully compressed. Road rollers are especially common when laying asphalt roads.

Compactor

- Cranes – Critical to lifting heavy objects into place, cranes are equipped with cables and pulleys and are used to raise and lower materials. A tower crane features a large, vertical mast and a huge horizontal crane arm extending from it. This machine allows the steel to be lifted to the increased heights found in multi-story buildings.

Crane

- Dump Trucks – These vehicles carry substantial bulk quantities of material to and from the construction site. Coal, dirt, gravel, sand, and waste are all heavy loads transported via these trucks.

Dump Truck

- Draglines – Used in both civil engineering and surface mining, these excavating machines feature a bucket pulled by a cable that drags materials horizontally during the excavation process.

Dragline

- Excavators – These are diesel-fueled machines equipped with a bucket attached to a two-part boom. Excavators are essential for digging trenches, holes and building foundations.

Excavator

- Graders– Equipped with a long blade designed to smooth out and flatten surfaces, these machines are critical in road construction and mining operations.

Grader

- Heavy Haulers – These large trucks carry oversized equipment and freight to the job site.

Heavy Hauler

- Loaders – Transporting large or heavy building materials such as bricks and pipes are these machines' role. Unlike the backhoe loader, these machines don't dig. They feature a large bucket on the front end to lift and move material.

Loader

- Mixer Trucks – These trucks are sent to construction sites to make concrete. They mix and churn cement, aggregate, and water.

Mixer Truck

- Pavers – Before the compactor can compress materials during road construction, the paver must distribute the paving material, such as asphalt, onto a road. Pavers distribute the material evenly, but the road still needs to be treated by a compactor or roller after the fact to ensure total compaction.

Paver

- Pile Boring Machines – These large machines drill a circular vertical hole into the ground, allowing workers to install steel supports for buildings.

Pile-Boring Machine

- Pile-Driving Machines – After the boring machines do their work, pile-drivers ensure that piles are driven into the ground at the appropriate depth. This machine is necessary for building foundational support.

Pile-Driving Machine

- Scrapers – Commonly used for earthmoving across tiny distances, a wheel tractor scraper, often referred to as a belly scraper, features a front blade that digs into the ground, and a conveyer belt moves the displaced soil into the scraper's rear bed. These machines are one of the primary pieces of equipment for road construction.

Scraper

- Telehandlers – To lift heavy and bulky materials to the height needed, the telehandler's telescopic boom can be raised and lowered as required.

Telehandler

- Trenchers – Resembling large circular saws or chainsaws, trenchers excavate soil to create trenches. There are two types of trenchers: wheeled and chained. Both are used to create channels for laying cable, pipe, or serve as drainage ditches.

Trencher

- Wrecking Ball Cranes – These machines serve the role of demolishing outdated or structurally unsound buildings. A large steel ball swinging into a structure can quickly bring it down.

Wrecking Ball

Heavy Construction

Not all construction projects are the same in respect to the scope of work performed. If someone builds a garden in their backyard, even a small-grade backhoe may be more equipment than they need. But heavy construction is a different beast, as it almost always requires large equipment such as a wrecking ball to demolish an old commercial building or a crane to lift heavy steel into place.

The heavy construction industry involves building civil engineering projects like roads, bridges, dams, and tunnels. Let's look at two of the common types of machines used for these projects: earthmovers and material handlers.

Earthmoving Equipment

Earthmovers are specially-designed vehicles with one primary purpose: move large amounts of earth to make way for upcoming construction projects. Those who built the Egyptian Pyramids mentioned earlier most likely broke ground with only a hoe, pick, and shovel. Thousands of manual laborers would have toiled to move the earth by hand, clearing the way for the Pyramids' construction. Today, machines carry out this type of backbreaking work and at a much faster pace.

Earthmovers are used worldwide in settings like civil engineering, mining, and road construction. One of the most common uses for these machines is to transition previously undeveloped land for urban and suburban development.

Common earthmovers include:

- Backhoes

- Bulldozers

- Dump Trucks

- Excavators

- Graders

- Loaders

- Trenchers

- Scrapers

As we highlight in our article, Construction Phases: From Start to Finish, excavators are one of the first pieces of earthmoving equipment to arrive on a construction site. They dig up the earth to prepare for the foundation and landscape of an upcoming construction project.

All earthmoving equipment allows construction crews to start a project with the proper foundation.

Material Handling

After excavators clear the land and move the earth, material-handling equipment enters the picture. Equipment in this category performs the vital role of getting all the initial raw materials, such as pipes, steel, and wood, where they need to be on a construction site. Once the material has arrived, these machines move it from one spot to another.

What kind of materials need to be handled? That answer depends on the specific construction task at hand, but any large load may require a material-handling machine.

Some common material handlers include:

- Cranes

- Loaders

- Heavy Haulers

- Trucks

We've only covered some of the heavy equipment used to move materials. There are still many manual devices used to transport small amounts of materials, such as your all-too-familiar wheelbarrow.

Top Companies Manufacturing Construction Equipment

- CASE Construction – This company has over 175 years of heavy machinery experience. Numerous industries count on CASE equipment, including agriculture, landscaping, snow removal, road and bridge construction, and more.

- Caterpillar – With over $41 billion in sales in 2020, Caterpillar Inc. is the world's largest construction equipment manufacturer.

- Hyundai -Operating in the heavy construction industry since 1991, Hyundai focuses on providing crews with quality excavators, loaders, and rollers.

- Volvo – Offering a vast product range, including excavators, haulers, pavers, compactors, pipe layers, and forestry equipment, you can find Volvo machines operating in the agriculture, construction, and mining industries.

Rental Equipment

Many construction companies can't buy all the equipment they require to finish projects or lack the space to store it when it's not in use. That's where equipment rental comes in! Renting heavy equipment can be an excellent plan for new and growing construction companies. Rentals allow companies access to the equipment and vehicles without the financial commitment of buying and maintaining such expensive machines.

It's a practice that is growing in popularity. However, there are pros and cons, like all business decisions made. One of the benefits of renting equipment is that you can avoid the risks of owning the machinery, conserve capital, and save on maintenance costs.

The drawbacks of renting equipment are pretty straightforward: more money is spent in the long run if you repeatedly rent the same equipment. When companies own the equipment, there is never any downtime as the company always has access to it.

Used Equipment and the Auction

What about buying used equipment? Some of the top companies mentioned above sell used equipment. The inventories at companies such as CASE and Caterpillar are constantly changing, which means you'll need to keep a lookout on their website for the machines you are interested in purchasing.

Another money-saving strategy is to purchase the equipment at an auction. There are many resources out there if you are thinking about buying used equipment at an auction. We recommend reading this article offering some straightforward advice for purchasing used equipment if you consider purchasing this way. We will leave you with a core recommendation: research should be at the core of any buying decision.

Safety

When operating, maintaining, repairing, or working around heavy equipment, the potential for fatalities is exceptionally high. The 4th highest cause for construction accidents is being caught in or between machinery, and this type of accident accounts for roughly 7% of all construction worker deaths. Whenever a machine is operating, all those working in the vicinity should be alert and recognize that hazards are present.

PPE is a crucial component to keeping workers safe. Hi-vis safety vests, hi-vis Jackets, hi-vis rainwear, and hi-vis shirts must be worn at all times on a construction site. Those operating heavy machines and equipment must be able to easily distinguish workers operating in other capacities on the job site. Also, devices have moving parts that can quickly eject flying projectiles at any time, which is why safety glasses are a crucial piece of gear workers wear.

Everyone on a construction site, especially those working around heavy equipment, should be wearing hi-vis safety vests.

Lastly, let's not forget about the maintenance workers who keep construction equipment and machines operating. Every piece of machinery must be serviced at some point. Maintenance workers replace defective mechanical parts and disassemble and reassemble equipment. Any time they perform these functions, hand injuries are possible. These injuries can range from chemical exposure to cuts and punctures to heat hazards. Those who rebuild mechanical components will most likely need welding equipment to keep them protected from sparks and hot metal.

Common Questions

Do I have to allow construction equipment to be parked on my property?

- It all depends on the city, the zoning ordinances, and the parking regulations that are established.

Where is Volvo construction equipment made?

- Manufacturing facilities are located all over the world. In the U.S, the Shippensburg, Pennsylvania location produces over sixty different models.

What construction equipment is most in demand?

- Earthmoving equipment, such as excavators and loaders, makes up the majority of the market.

PPE: Equipment All Construction Workers Need

At MCR Safety, we are known for one thing: protecting people. Our PPE keeps construction workers safe, whether they're using earthmovers, material handlers, or any other construction-site equipment.

We encourage all construction professionals to check out our dedicated Construction industry page, covering hazards and recommended PPE across ten individual construction fields.

MCR Safety Construction Industry Resource Page

When it comes to preventing injuries on the worksite, MCR Safety is the expert in providing the appropriate PPE to keep you safe. If you're a construction professional, we encourage you to check out our dedicated Construction industry page, covering hazards and recommended PPE across ten individual construction subsector pages.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's on the shop floor, an oil rig, or a construction site, we are there to provide solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

About the Author

Related Articles

Construction Phases: From Start to Finish

According to the National Association of Homebuilders, the average time it takes to build a new...

Different Types of Construction Contractors, Explained

Constructing or renovating a home or building takes an army of people — and there are 7,439,360...

Types of Construction Framing and Framing Gloves

In the building process of any structure, Framing comes after the foundation is poured and has...

Construction Jobs: Skilled vs Unskilled

Those who work in construction fall into one of two categories: Skilled or unskilled workers....

Essential Construction Tools and Hand Tool Safety

For over three million years, tools have been the cornerstone of man creating everything you see...

Common Construction Accidents and Injuries

Working conditions on construction sites are continually changing, and workers must be ready for...

Exploring the Role of Construction Safety Jobs

The construction industry is unlike anywhere else you might find employment. Working in...

A Detailed Look at Construction Spending

A number that is continuously changing yet essential to watch is the dollar amount placed on...

A Comprehensive Look at Construction Plans

All construction workers need to be updated on a project's schedule as it progresses. Also, they...Latest Articles