10 Jul 07/10/2021

Sharing Insight into Hi-Vis Safety Vests

Work safety vests are a necessary form of protective clothing for workers across numerous industries. This type of safety gear ensures that others nearby can clearly see workers operating in low-light environments by providing visual recognition during both day and night operations.

Hi-vis safety vests are one of the most worn types of personal protective equipment (PPE) and are easily recognizable as crucial safety gear. The demand for high-visibility clothing has been on the rise over the past several years, as more and more companies recognize the needs to keep workers seen across work sites.

MCR Safety supplies over 100 types of safety vests in multiple configurations and colors.

So, who sells safety vests? MCR Safety is one of the leading safety brands in America, and we've been selling and supplying safety vests to markets all over the world for decades now. Our products are stocked by some of the leading industrial distributors servicing end-users.

This article will highlight everything a user could want to know about safety vests, from the workers who use them to the standards that ensure they are protected. Our opening sections highlight some of the requirements and standards of safety vests. We also explore some of the industries that require increased visibility. For those who prefer learning more about the product itself, use our left-hand navigation to jump directly to the vest material section.

OSHA Requirements

Are safety vests required by OSHA? The Occupational Safety Health Administration (OSHA) general-duty clause dictates that PPE must be provided at no expense to workers whenever hazards can't be removed from the worksite. One such hazard is anyone coming into close contact with vehicular traffic and who is at serious risk of not being seen due to poor lighting.

OSHA requires that employees working on highway or road construction, for example, wear gear that makes them easily visible to drivers.

As we highlight in our PPE article, OSHA 1910.32 is the governing regulation for personal protective equipment, and it requires that employers provide it at no cost to employees. Safety vests are a form of personal protective equipment, which means they must be provided to workers.

OSHA requires that PPE meet performance safety standards developed by the American National Standards Institute (ANSI). This kind of oversight is meant to keep American workers safe no matter what their profession. Concerning safety vests, OSHA leans on ANSI recommendations for vest standards.

What Is ANSI?

As we describe on our ANSI article, ANSI is an acronym for the American National Standards Institute. Founded in 1918, it is a non-profit organization that reviews and manages standards for products, services, processes, and systems in the United States. ANSI does not create standards, but it approves standards established by representatives of organizations focused on the development of standards.

ANSI 107-2020 is the standard that sets the rules for high-visibility clothing, which includes safety vests. Under 107-2020, several areas distinguish hi-vis safety vests. Here is a breakdown of the three core areas:

- Visible Colors – get people's attention. A hi-vis garment's background material must be a fluorescent color: yellow-green, orange-red, or red. A vest must have a minimum amount of fluorescent background material used in its construction to achieve a specific performance class. You'll see the required amounts for each performance class in the table below.

- Reflective Striping – improves a person's visibility in low-light environments, such as at dusk, during bad weather, or at night. This happens because of retro-reflectivity, which returns light back to the original source. More on retro-reflectivity is discussed below.

- Testing – sets standards for safety vests. An accredited laboratory must test all hi-vis vests to ensure each garment meets ANSI 107 test requirements. Once testing is finalized, MCR Safety provides a Declaration of Conformity with each model.

The above graph shows all the specific requirements around Type O, Type P, and Type R safety vests. Here is what each one means:

- Type O Vests – refers to vests designed for occupational workers, such as off-road and warehouse workers, who require being seen but are not required to wear Class 2 or Class 3 protection. Due to the negligible cost difference and performance difference between general-purpose safety vests and Class 1 Type O vests, MCR Safety only stocks general-purpose styles.

- Type P Vests – are primarily designed for emergency personnel such as EMS, incident responders, and law enforcement.

- Type R Vests – are designed for those working around vehicular traffic, such as roadway and temporary traffic control zones.

Vests are further broken down within each type into different class ratings, highlighted more in-depth below. Before you choose a specific class-rated safety vest, be sure you've performed a thorough hazard assessment to determine the risks faced by workers. If there are many moving vehicles and equipment in a specific operational area, the last thing you want to do is choose the incorrect rating for your vests. We can help! Click the 360° icon below to schedule one of our team members to provide an onsite hazard assessment.

Construction, Traffic, and More

What is a safety vest used for at work? Employers and companies that run operations in potentially hazardous environments should ensure that their employees wear high-visibility safety vests to maintain safety. Industries such as construction have seen increased regulations where workers must now wear Class 2 hi-vis vests.

Construction workers at all types of construction sites should wear safety vests. Many sites contain moving equipment and vehicles, and visibility is key to safety.

Under OSHA regulations, employees working at certain sites and specific jobs must wear safety vests. One example is a road construction site. Those working around highways, such as construction laborers and flaggers, must wear hi-vis safety vests at all times.

Outside of construction, who needs to wear a safety vest? There is a laundry list of other industries that require hi-vis safety vests. With our decades of experience servicing industries, we've identified more than twenty end-markets requiring hi-vis gear. Here's a look at some:

- Airports - Workers who handle baggage and work within the path of taxiing airplanes and other vehicles at airports should all wear safety vests.

- Crossing Guards - As crossing guards guide and control pedestrian traffic and passing cars, good visibility is a must since many works directly on or near busy roads.

- Drone pilots - fly crewless vehicles. Since they're often standing in fixed positions, they must wear hi-vis gear to be easily identified by others on a job site.

- EMS Paramedic - As paramedics assess and apply medical care to individuals, they must remain visible to other emergency service workers and vehicles.

- Firefighters - combat flames, keeping us all safe. Fire and rescue teams that arrive on a scene need hi-vis gear to keep them safe and visible.

- Highway workers - maintain highways and many other municipal and non-municipal roads that involve traffic and passing vehicles, meaning visibility is essential to safety.

- Hunters - who trap, catch, or kill animals need to be visible to other hunters and people, especially if firearms or other dangerous equipment are involved.

- NRA Range Officers - manage firing ranges and are knowledgeable about a variety of firearms. They also know that safety must always be maintained, and staying visible means staying safe.

- Parking Lot Attendant - Working at a parking lot means there's a lot of traffic moving in and out as cars are constantly being parked and picked up. When moving vehicles are present, stay visible.

- Photography - As photographers capture and photograph their surroundings, they should remain easily visible, especially when stationary. This is especially important when working around traffic on the shoulder of a road.

- Police officers - have to be highly visible when conducting traffic and also when performing many other everyday tasks.

- Railroads - While railroad workers build, install, and maintain railroads, they must remain visible to any passing trains or other vehicles.

- Roadways Workers - on roadways encounter vehicles and passing cars continuously. Visibility is a must.

- Safety Officers -as safety officers review, evaluate, and analyze work environments, visibility is essential, especially in hazardous environments that involve moving equipment.

- Surveyors - when surveyors take measurements, they might be at construction sites, roadways, or properties with many other activities. Since they're often stationary, staying safe means staying visible.

- Security and Event Staff - deal with many different scenarios and situations. They should be highly visible to other workers, personnel, and the public, especially when responding to safety calls.

- Shipyard Workers - operate and handle massive equipment and components. For safety, it's necessary to maintain visibility while working next to such large vessels.

- Traffic guards - direct traffic through construction sites and work zones. Since they work next to passing cars and other moving vehicles, visibility is always important.

- Utility Lineman - install and repair cables often close to roadways or traffic, they need to remain visible.

- Waste Management - while preparing and sorting recyclables and other materials, there is heavy machinery and other equipment in operation. Visibility increases safety.

- Warehousing - wherever machinery is operating and moving around people at work, it makes sense that everyone can easily see who is near one another.

In addition to the occupations named above, there are other industrial and personal or recreational applications where safety vests might be worn: delivery drivers, forestry workers, highway emergency personnel, landscaping, municipal workers, roadside cleanup, volunteer staff, dog walkers, bicyclists, motorcyclists, hikers, and joggers.

Vest Material

Most of our high-visibility options are made from polyester material, a synthetic fiber, meaning it is a fiber not made from animal or plant material but a specific set of chemical reactions. Polyester is an excellent choice for safety vests because it can absorb the dyes that give the garment its brilliant fluorescent colors while also holding those colors for extended periods. Other materials, such as nylon or cotton, tend to release colors more quickly and lose the luster that makes the garment high-visibility.

One major downside to polyester is that it's not the most eco-friendly product. It can take centuries to degrade in the natural environment. However, MCR Safety is developing ways to make safety vests more eco-friendly. We now have vest options made with recycled materials.

With construction alone employing over 7 million workers requiring protection, think of how many used safety vests wind up in trash cans. With our new recycled vest lineup, Mother Earth has someone protecting her, too!

Also, polyester isn't flame-resistant, making it susceptible to flames and heat. This is discussed further in our flame-resistant section below.

Reflective Overview

Reflectivity is the key to being visible in low-light environments. When light hits a surface, such as a highway or an ordinary T-shirt, it will bounce or scatter in just about every direction. But, when light hits the reflective material on an MCR Safety Class 2 or 3 safety vest, retroreflection occurs.

Retroreflection happens when light bounces from a surface that is engineered to return light in its source direction. If a person is wearing a retroreflective material, the retroreflected light stands a better chance of being seen. While retroreflection does occur during the daytime, there is little or no contrast between the reflected light and the sun's natural light. Because of this lack of contrast, it is necessary to use fluorescent colors in daylight to increase visibility.

A retroreflective vest, shirt, or jacket that reflects a high percentage of headlight beams is almost always required for night work. And, if you're working at night, having the best reflectivity makes the most sense, which is our Class 3 option.

Class 3 Safety Vests

![]()

MCR Safety's Class 3 safety vests offer the highest level of visibility and have the most significant amount of fluorescent background material, allowing the wearer to be more conspicuous in their environment during daylight hours. They also have more reflective material, returning more visible light to be perceived as a possible source of danger in low-light situations. An example of this would be the light from the headlamps of a car bouncing off the safety vest back to the car, allowing the driver to identify a person who may be in harm's way.

We've assembled our top-selling styles for you!

Class 3 garments allow the wearer to be identifiable as a person and remain conspicuous through a full range of motion at a minimum of 1,280 feet away. These garments are recommended for individuals working around vehicles going 55 mph or more. Simply put, Class 3 visibility is for workers in dangerous high-traffic areas working in poor light conditions. The additional reflective materials used in Class 3 safety vests help identify workers better and more quickly.

Our new cost-effective Class 3 safety vest

Have you avoided wearing higher-rated Class 3 safety vests due to the increased costs? If so, you might want to check out our VCL3MLZ, which utilizes cost-competitive materials, providing users with a budget-friendly option. We made it in a mesh design, too — a design that keeps you cool and comfortable!

Our WCCL2l has been a popular seller for decades now, primarily because it features additional orange trim on each side of the reflective tape. We decided it was time for a similar version of the orange trim style but made with Class 3 visibility.

Class 2 Safety Vests

![]()

What does Class 2 mean in the world of safety vests? This type of vest is one step down from a Class 3 vest in the vest's background and reflective materials. In contrast, Class 2 vests are made from the same high-quality background and reflective materials as Class 3 vests. Their only difference is they offer less coverage (775 sq. inches of background material with 201 sq. inches of reflective material). The most noticeable difference is that Class 3 vests have half sleeves, while Class 2 offerings are sleeveless.

MCR Safety carries a wide variety of ANSI/ISEA 107-2010 Class 2 safety vests. We've assembled our top-selling ones for you to consider!

Class 2 safety vests provide visibility protection for anyone operating in low-light environments. When traffic surpasses 25 mph and is below 50 mph, Class 2 rated vests are considered best. Anyone acting as a flagger, laborer, or survey crew requires these safety vests.

Economical and Budget-Friendly

General-purpose safety vests offer high visibility at a nominal price and can be used in applications where the need for ANSI-rated vests is not present. A variety of non-ANSI vests fall under this category, including non-reflective safety vests, vests with multiple colors and styles of reflective material, incident command vests, and adjustable sash options.

Some people want only the cheapest product, primarily because the product will be thrown away by the end of a workday. As long as specific class standards don't have to be met and there is no equipment moving at high speeds, general-purpose safety vests provide bright fluorescent colors to help you stand out in your environment at a low price point. Our V201 is an example of a non-ANSI vest providing users with a low-cost alternative.

VMLBA is our first non-ANSI-rated vest that features a breakaway design for easy removal.

Class E Hi-Vis Gear

ANSI Class E clothing is ideal for increasing your overall visibility on a work site. You can combine your ANSI Class 2 vest with one of our Class E products, creating an ANSI Class 3 ensemble for higher-level visibility. Class E apparel can include mesh pants, leg gaiters, elastic pants, and bib pants.

Leg gaiters, shown above, also meet ANSI-107 Class E standards. When worn with Class 2 garments, the overall classification is considered Performance Class 3.

Flame-Resistant (FR) Hi-Vis Vests

Are safety vests flammable? They are if made with polyester. While polyester is an excellent material for manufacturing safety vests because it holds brightly colored dyes so well, it is easily flammable, making it unsuitable for workers who need arc-flash or flash fire protection.

Check out the above image of our inherent FR vests taking on flames in an 84kW/m2 heat flux-based flash fire.

Inherent flame-resistant (FR) vests use a mesh modacrylic/aramid blend fabric to give them self-extinguishing abilities. Since many worksites involve flame hazards, have flammable material on site, and involve moving vehicles and traffic, hi-vis, FR vests can be crucial pieces of PPE.

Safety vests such as MCR Safety's FRMCL3ML and FRMCL2ML are made with a GlenGuard® mesh lime modacrylic/aramid blended fabric with FR reflective stripes, providing safety against flames while maintaining visibility.

Limited-Flammability Vests

As we highlight in our limited-flammability article, these products are considered to have "limited-flammability" since they have been chemically treated for flame resistance. LF vests have been tested to method ASTM D-6413 to observe the materials' reaction to an open flame and will self-extinguish within a matter of seconds, once the source of the flame is removed.

VCL2MLFR

These vests are intended for workers who may have incidental contact with heat, heated objects, or flames, working in a capacity where short-term protection is needed. They are not intended for those needing arc-flash protection.

Incident Command Vests

Many of today's environments require the quick identification of individuals coordinating or involved with emergency site activities. Although incident command vests were initially designed for responders to disasters or hazardous situations, they are now used in a wide variety of applications. They are worn to help quickly identify the person or department responsible for a particular area.

Women's Fitted Safety Vest

Over 75 million women in the American workforce, and those who require safety gear will need personal protective equipment that fits properly to ensure their safety. We've assembled numerous types of safety gear that accommodate their requirements. For example, with regards to safety vests, many women require a slim fit. So, MCR Safety's LVCL2ML Class 2 safety vests are specially designed just for women. They are ideal for those who need a lightweight and comfortable high-visibility option.

Within each safety vest category mentioned above, there are specific features that set each vest apart. We've created a separate article to explain these core features: breakaway, mesh, pockets, zippers, different colors, heavy-duty styles, and more.

Common Questions

Is a safety vest considered PPE?

- Absolutely! A safety vest is considered personal protective equipment (PPE), as it keeps you seen in hazardous environments such as low light.

Should gardeners wear a safety vest?

- As we highlight in our Gardening Gloves article, gardeners face numerous hazards. If a gardener is working at night or around moving equipment, a safety vest should be worn.

Is it illegal to not wear safety vests in a warehouse?

- If the question pertains to complying with OSHA requirements because hazards are present, then a company is violating OSHA 1910.32.

How to screenprint safety vests?

- All MCR Safety vests can be imprinted with your logo! We screenprint our vests at our central corporate production facility based outside Memphis, Tennessee. If you're interested and would like to visit our facility, we would be happy to show you how screenprinting works.

Who sells safety vests?

- You can leave us a comment below, and we will have one of our industrial distribution partners provide a quote. For immediate trials, visit our Buy and Try site.

Does the ANSI 107-2020 publication of the standard replace the 2015 version?

- Yes, the 2015 version is now outdated.

Keeping You Seen and Safe

Our mission at MCR Safety is to keep you protected, whether you're encountering sharp objects, chemicals, or low light. We hope the above information on our safety vests will help keep you visible and identified on any job site you work.

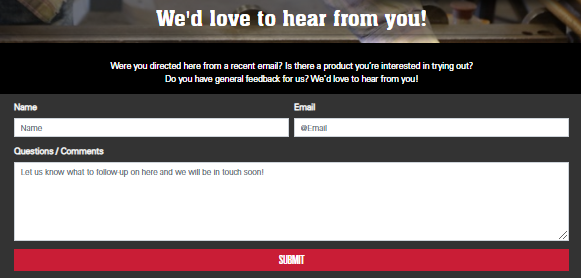

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's on the shop floor, an oil rig, a construction site, or shooting outdoors, we are there to provide solutions to workplace (and recreational) hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

About the Author

Latest Articles