22 May 05/22/2021

Solar Panel Installation Safety

Solar panels have become an essential part of the energy landscape in the 21st century. Whether owned by individuals, private companies, or municipalities, solar panels contribute to our overall energy supply by generating "clean" energy.

MCR Safety has solar panels on top of our brand-new manufacturing facility producing NXG gloves!

At MCR Safety, we know a little something about solar panels. Our brand-new manufacturing facility that produces our NXG gloves utilizes sustainable energy by using solar panels rather than relying on coal, natural gas, or petroleum. We also know that the PPE we provide finds its way onto solar panel installers looking for top-quality on-the-job protection. Solar panel installers face inherent dangers that come with the job. And, with solar panels growing in popularity, it looks like there will be a high demand for protection over the next decade.

The President's 2021 infrastructure plan calls for over $100 billion to be spent on clean energy to put the US on a path to producing 100% carbon-free electricity by 2035. To achieve the 2035 goal, the Solar Energy Industries Association (SEIA) says that 50% more solar capacity will need to be installed nationwide. It sounds like MCR Safety will be busy protecting a lot of workers over the next 14 years!

This article will explore the science of solar panels, the activities solar panel installers perform, and the PPE required to keep them safe.

How Do Solar Panels Work?

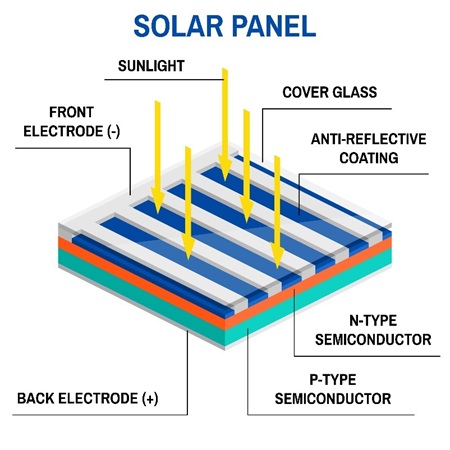

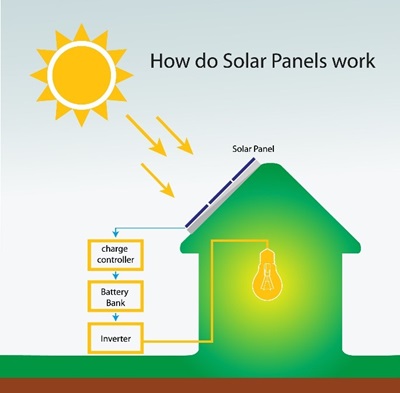

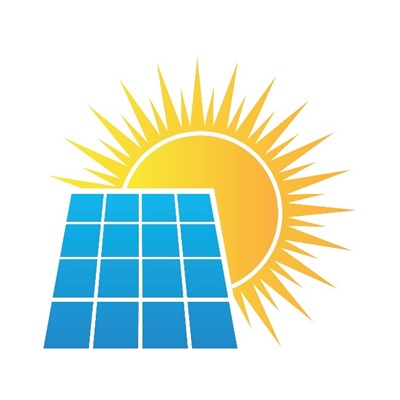

The term photovoltaic describes something that transforms light into electricity. Solar panels work because they are made up of multiple photovoltaic cells, made from semi-conductive materials such as silicone, that free electrons from atoms when exposed to light. Each cell is layered between the semi-conductive material, allowing for a positive and negative charge to occur.

There are essentially five steps to turn sunlight into electricity:

- When sunlight hits the cells of the solar panels, it produces an electric current (DC).

- The electricity created by the field flows to the panel's fringes and then flows into a conductive wire.

- Electricity moves from the wire to the inverter, which transforms the DC power to AC power.

- Meanwhile, another wire carries electricity to the breaker box, distributing energy throughout a building.

- Any unused energy flows through the meter and into the electrical utility grid.

As researchers have recently produced adaptable solar cells that are only 1.3 microns thick, solar technology is steadily advancing. These featherweight cells are 1/1000th the width of a human hair and are 20 times lighter than your typical sheet of printer paper! As solar technology continues advancing, it means more areas of everyday life will incorporate it.

Installation

Who installs solar panels? The technicians who install solar panels are called solar photovoltaic installers, solar installers, or PV installers. They both install and maintain solar panels, regardless of the location. Panels are installed on the roofs of private homes and businesses, as well as on solar farms. Currently, there are 12,000 solar installers finding employment in the US. However, jobs are expected to grow in this industry by 51% by 2029, and that number may not include estimates based on the new infrastructure spending.

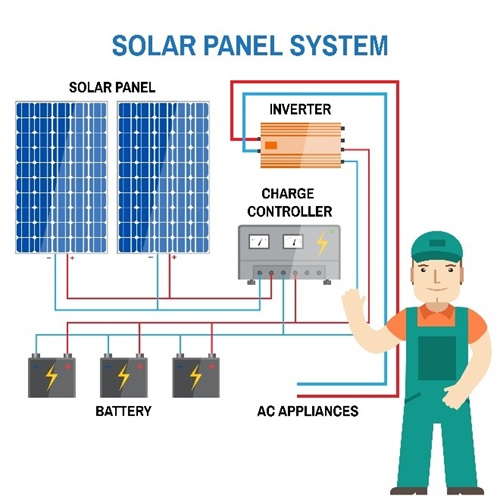

Installers link all the devices pictured in the image into one functioning unit that produces electricity.

Most PV installers are trained on the job. However, hiring managers often prefer employees with a high school diploma and some technical training or experience.

Jobs

The US Bureau of Labor Statistics (BLS) highlights the top trades employing solar installers. Electrical contractors and HVAC contractors are the two industries hiring the most solar photovoltaic installers currently.

We cover both trades in-depth on our Construction Industry page.

Installer Work Activities

Solar installers work mostly outside, on roofs, and above ground to connect wires to the electric grid. They may also work in crawlspaces of the home to connect wires. Installers have to adapt the solar panels to the roof structure, since a flat roof will require a unit to be mounted at an angle.

The day-to-day responsibilities of a solar installer include:

- Assembling solar panels, modules, and their support structures

- Applying weather sealing to the entire module and its support mechanism

- Installing electrical components of the panels and solar system

- Selecting appropriate construction materials for each job

- Installing active solar systems, which can include solar collectors, concentrators, pumps, and fans

- Cleaning solar panels

- Soldering wires

- Handling hot water collectors

- Covering panels

One thing is sure across all these activities: hazards come with the job.

OSHA

The Occupational Safety Health Administration (OSHA) supports green jobs, making solar energy a focal point for the administration. Green jobs are defined as jobs that help to improve the environment. However, OSHA emphasizes that not all green jobs are inherently safe.

This website from OSHA highlights the hazards faced by installers, and seeks to help them understand the working conditions faced. Our next section pays close attention to the risks of installing and maintaining solar panels.

Safety Concerns and Hazards

Every industry has its unique safety concerns, and solar installation is no different. The biggest problems for installers are lifting, heat, materials handling, and chemical exposure.

Lifting

An installer's daily activities include lifting, positioning, transporting, and holding panels.

Solar panels are large and unwieldy. They must be handled carefully, not just to protect the panels themselves but to protect the workers who are installing them.

Heat

Have you ever stepped inside an attic during the hot summer? The intense heat of summer can be an issue for installers who spend their days exposed to the elements working on rooftops. Workers need to be prepared to combat heat stroke, dehydration, and heat exhaustion.

Materials Handling

Solar panels can easily injure a worker. Solar panels can get hot quickly in the sun, and their sharp edges and heavy, clunky nature can lead to injuries that include cuts, bruises, scrapes, pulled muscles, burns, strains, sprains, and broken bones.

Chemicals

From the manufacturing process to installation, those who work with solar panels may be exposed to many chemicals, such as telluride, cadmium telluride, gallium, and germanium. Hydrofluoric acid, as well other acids and alkalis that are used in the cleaning process, each presents its individual hazard. Solar panels may also pose carcinogenic risks, so it is vital to protect workers from exposure to these dangers.

UV Exposure

Ultraviolet radiation from working in the sun all year is a primary concern!

Hot Equipment

Solar panels begin to heat up as soon as they are uncovered, and then they bake in the sun all day long. That means that they are often very hot during the installation process and maintenance tasks. Installers should look at safety gear to protect against burns in addition to cuts and scrapes when they consider their PPE.

Flying Particles

Whenever power tools like drills are used, there is a chance for objects and debris to be thrown from the equipment. Installing solar panels requires soldering parts into place, and liquid solder can splatter into a worker's eyes.

Electricity

Anytime you're working around electricity, there is the potential for hazards to cause injury and even death.

Injuries

According to the Oregon Occupational Safety and Health Division under the Department of Consumer and Business Services, solar panel installers face many potential injuries from various hazards.

Potential injuries include:

- Falls from ladders and roofs

- Shocks from electric currents

- Burns from hot equipment, including panels

- Cuts from metal and power tools

- Eye injuries

- Arc flash

- Soldering burns

- Sunburn

The best way to reduce the risk of injury is to use safety equipment, and MCR Safety offers what you need. Take a look.

PPE

OHSA Regulation 1910.132, the General Duty Clause, requires all employers to ensure a workplace that is free from recognized hazards that are likely to cause death or serious physical harm. When threats can't be removed, personal protective equipment (PPE) must be provided.

Below is the PPE MCR Safety supplies that protect installers:

- Eye protection – is necessary to protect the eyes from splattering hot solder, UV rays, flying particles, dust, or debris. This protection may come in the form of safety glasses, face shields, and safety goggles.

- Hi-vis clothing – is essential for installers to stay seen on busy construction sites. Options made from breathable, lightweight material is key.

- Insulated hi-vis clothing – installers are exposed to all types of weather, including cold winter months. We now stock numerous insulated options.

- Chemical-resistant gloves – offer protection from harsh substances, such as lead and acid. Both chemicals are present in solar panels.

.png?h=314&w=600&hash=957449DD59FE34CE3DBF6ACFC533BD0F)

- Cut-resistant and heat-resistant gloves – protect a worker's hands when moving all of the materials and parts used in solar panels. The sharp-edged collector manifold can get hot, which means cut-resistant gloves made with DuPont Kevlar are ideal. Kevlar is inherently heat resistant!

- Cut-resistant sleeves – protect one's arms during the handling of panels.

- FR clothing – is essential when working around electrical hazards that can result in arc flashes. Our triple-vented FR shirts are ideal for those working in the hot sun!

- Moisture-wicking products – ensure workers stay cool when working outside. We offer hi-vis shirts and gloves with moisture-wicking properties.

- FR long-sleeve shirts – are required when using a plumbing torch and soldering joints. Both activities can cause synthetic materials to melt and burn.

- Steel-toe boots – are required on virtually any construction site to protect feet from drop hazards.

Solar installers may also want to consider reading these other MCR Safety articles outlining additional hazards they may face and the ways to stay safe:

- Ladder Safety

- Heat Stress

Common Questions

How much do solar panels cost?

- You have to factor in any tax credits you might receive, but solar panels typically cost anywhere from $11,000 to $15,000 per home on average.

How many solar panels do I need?

- It depends on your average monthly use of kilowatt-hours and the amount of sun your home receives. There are online calculators to help you find the optimal number of panels needed for your home solar system.

Are solar panels worth it?

- The world's countries are moving toward clean energy. It makes sense to begin investigating the pros and cons of investing in solar panels. One pro is that solar panels lower an owner's electrical bill. One con is that not all roofs easily allow for panel installation.

Protecting Solar Panel Installers

MCR protects workers, and that includes solar panel installers! We provide workers with the PPE they need to avoid the risks associated with performing the responsibilities of their installation jobs.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's on the shop floor, an oil rig, a construction site, or shooting outdoors, we are there to provide solutions to workplace (and recreational) hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

About the Author

Related Articles

Construction Phases: From Start to Finish

According to the National Association of Homebuilders, the average time it takes to build a new...

Different Types of Construction Contractors, Explained

Constructing or renovating a home or building takes an army of people — and there are 7,439,360...

Covering Insights into Cut Resistant Sleeves

Most often, sleeves are worn in conjunction with cut-resistant work gloves. MCR Safety offers...

Electrical Contractors and Lineman Jobs

Electricians, linemen, electrical contractors—all of these jobs play an important part in modern...

Hi-Vis Shirts: Staying Safe, Seen, and Stylish

Being visible to drivers who may not be aware of what's going on around them is critical. When...

OSHA and Safety Glasses

OSHA requires employers to provide eye and face protection for all employees. Both employers and...Latest Articles