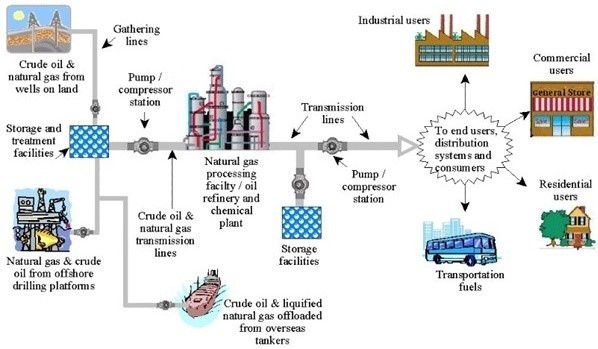

The midstream industry collects and transports crude oil, natural gas, refined petroleum products, and slurry. Companies across this industry provide the vital link between producers and refiners. This means moving oil and gas across miles and miles of pipelines to industrial, commercial and residential end-users.

A look at the flow of oil and gas across the industry

Pipelines, tank terminals, and oil tankers are all examples of the infrastructure required for transporting crude oil and gas.

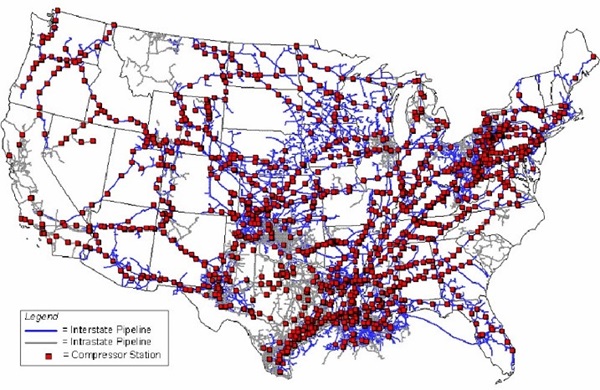

Oil and Gas from upstream production wells are sent through a network of small pipelines, usually 2 to 8 inches in diameter, to a central operating location. Treatment facilities and processing plants are the common destination. In the US alone, there are over 72,000 miles of crude system lines and another 2 million total miles of mainline and other natural gas pipelines.

| Pipe Material | Total Miles |

|---|---|

| Plastic | 689007.4 |

| Steel | 544307.8 |

| Iron | 29982.8 |

| Other Materials | 930.2 |

| Copper | 19.9 |

Most gathering and transmission pipelines are made of plastics and steel. Be sure to check out our Steel Pipe Manufacturing page.

| Main | Services | Total Miles | Operator Count | |||

|---|---|---|---|---|---|---|

| Calendar Year | Total Miles | Operator Count | Total Miles | Operator Count | ||

| 2017 | 1,295,944.9 | 1352 | 921,057.7 | 1357 | 2,223,003.7 | 1372 |

| 2016 | 1,286,754.9 | 1353 | 923,563.1 | 1359 | 2,210,318.0 | 1374 |

| 2015 | 1,277,025.2 | 1345 | 913,129.8 | 136 | 2,190,154.9 | 1368 |

| 2014 | 1,266,408.7 | 1362 | 902,903.4 | 1371 | 2,169,312.1 | 1385 |

| 2013 | 1,255,383.6 | 1363 | 894,352.8 | 1370 | 2,149,736.3 | 1387 |

| 2012 | 1,247,706.4 | 1350 | 890,429.3 | 1357 | 2,138,135.8 | 1373 |

| 2011 | 123,176.6 | 1331 | 882,022.3 | 1333 | 2,121,198.9 | 1349 |

| 2010 | 1,229,884.1 | 1320 | 872,528.1 | 1318 | 2,102,412.2 | 1335 |

Pipeline infrastructure is increasing

Pipelines are primarily connected to the largest natural gas supply areas: Eagle Ford, Marcellus, Bakken, Utica, Uinta Permian, Haynesville, Fayetteville and Barnett. Natural gas production has increased rapidly in recent years, due to activity within the Utica and Marcellus Shale natural gas formations, increasing the need for additional field gathering pipes.

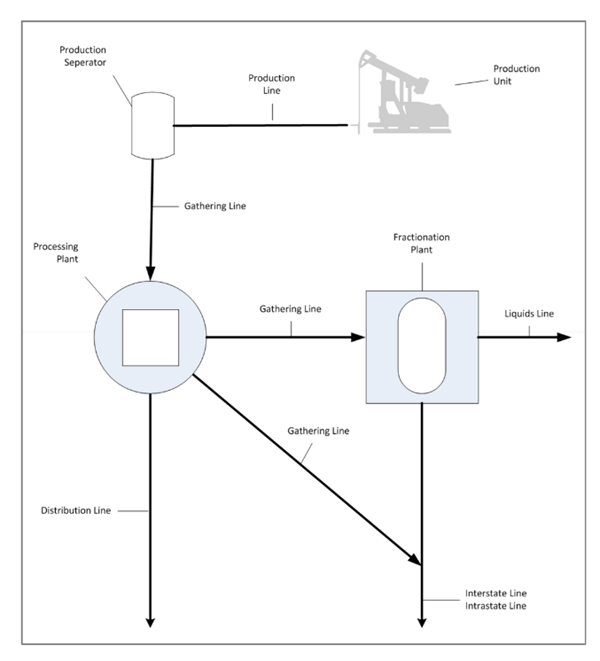

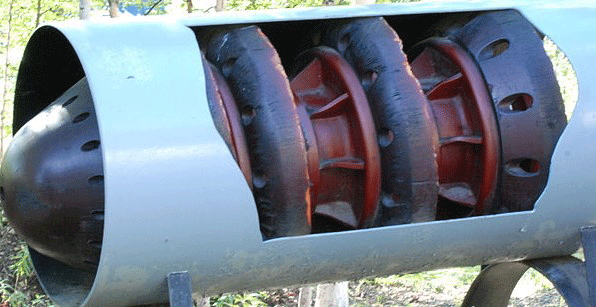

Example of Field Gathering

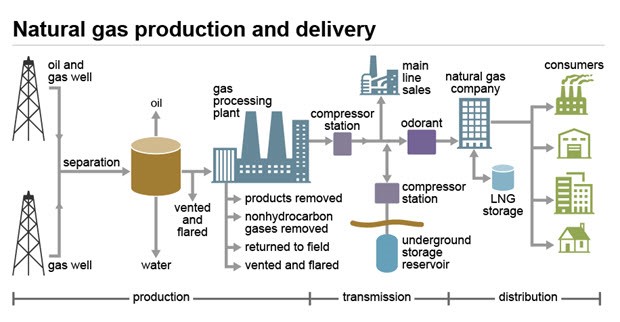

Surface facilities measure the production rate of oil, gas, and water that is produced. Most importantly, these facilities separate oil, gas and water from one another, while also removing impurities. Natural gas processing plants separate hydrocarbon gas liquids, non-hydrocarbon gases, and water from the natural gas.

Gas Processing Plant Capacity

Oil-Water Separators

Involves transporting crude oil and natural gas over long distances.

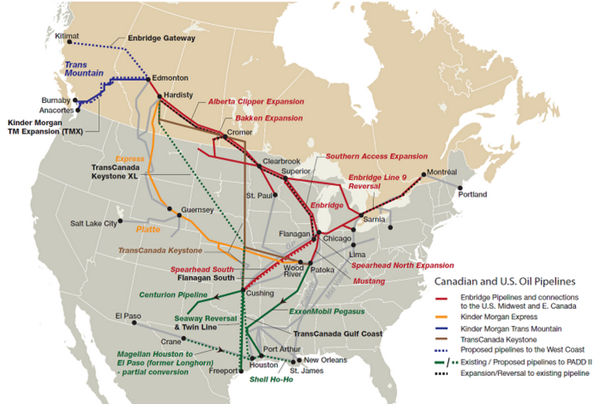

Visual Map of US Natural Gas pipelines

Crude Oil Pipelines

Crude oil flows across the US’ vast pipeline transmission and distribution infrastructure. The Trans-Alaska pipeline carries an average of 1.8 million barrels of oil a day.

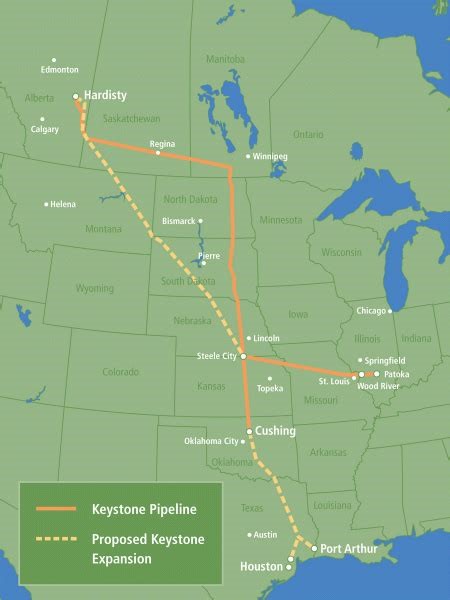

In recent years, the Keystone Pipeline, a proposed extension, beginning in Hardisty, Alberta, and extending south to Steele City, Nebraska, has been a hotly debated discussion point. It will eventually transport oil from Alberta, Canada to refineries in the United States.

Oil is sent this way when there is little infrastructure, like in North Dakota’s Bakken area, or when more flexible options are preferred. In 2012, around 75% of Bakken’s oil was transported by truck. That number has been dropping in recent years, due to increased midstream infrastructure.

Tank Cars carrying crude oil

Storage Terminal

Methods include field tank batteries, product bulk terminals, refinery tanks and holding tanks.

Natural gas is stored underground due to its’ temperature. Since natural Gas cannot be stored near or at the well, there are some slight differences in the process.

Excellent visual for natural gas processing and storage

In 1942, America was at war with the Axis Powers. Vessels carrying oil were sunk all across the Gulf of Mexico and eastern shores. To maintain the flow of oil, a massive pipeline was needed, providing oil from Texas to the east coast. The solution was the “Big Inch” pipeline, constructed with 24 inches in diameter pipeline! Without a gigantic pipeline, some historians question whether the Allies could have won the war. Following are pictures from the Library of Congress.

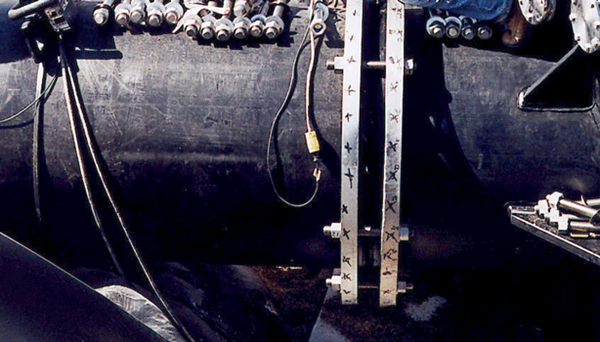

Welding on the “Big Inch” Pipeline

Gulf of Mexico Ships Sunk

East Coast Vessel Sunk

When external factors are not in play, like a war, the pipeline and transportation industry still finds itself stuck in the middle between producers and refineries. Strong demand from commercial, industrial and retail markets influences upstream production. However, when the economy slumps, there is less refining activity, meaning less oil is needed from producers. Both of these scenarios affect pipeline infrastructure, which in turn affects the number of workers needed for developing the pipelines.

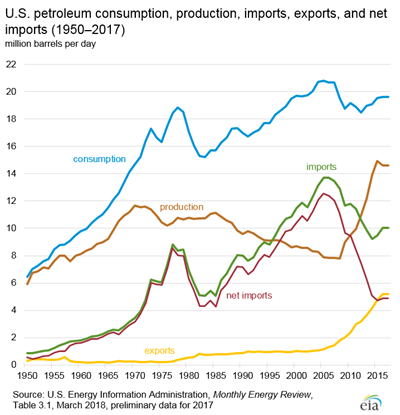

Production dating back to 1950

The good news is the world needs more pipeline infrastructure to keep up with demand. The IEA concludes that another $640 billion investment is needed for E&P spending through at least 2040, an increase over the current $430 billion. A ramp up in pipelines and pipeline infrastructure will be on the rise for years to come.

Midstream companies are in the business of moving oil and gas around from point A to point B. Here are some of the largest:

| Company | Total Employees |

|---|---|

| Koch Pipeline Company | 120,000 |

| Phillips 66 | 14,600 |

| Enbridge | 11,000 |

| Kinder Morgan | 10,800 |

| TransCanada | 7,200 |

| Enterprise Product Partners | 6,800 |

| Sunoco | 6,500 |

| Plains All American | 5,000 |

| Spectra Energy | 5,700 |

| Centurion Pipeline | 2,900 |

| Company | Total Employees |

|---|---|

| Sinopec (China) | 249,142 |

| Transneft (Russian) | 106,000 |

Transeft and China National Petroleum Corporation part of the IAOT, International Association of Oil Transporters, which supports oil transportation and storage on international, national and regional levels.

Here is a look at some of the workers found across the industry and that are impacted when demand fluctuates: (Click an occupation to expand and learn more.)

Perform tasks involving physical labor at construction sites. There are roughly around 2,600 of these workers found in Pipeline Transportation. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Helper, Laborer, Post Framer, and Construction Worker.

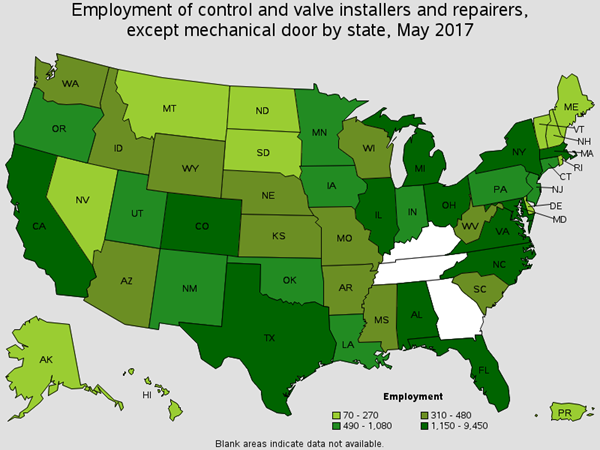

Install, repair, and maintain mechanical regulating and controlling devices and other mechanical governors. There are a little over 1,700 of these workers in Pipeline Transportation. You will find these workers repairing mechanical control devices, lubricating mechanical parts, and installing electric meters. Common job titles for this worker are Control Valve Technician, Service Technician, and Valve Technician.

Employment of Control and Valve Installers and Repairers

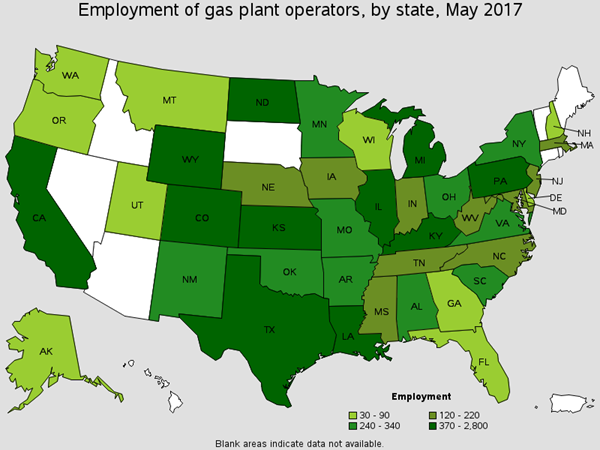

Distribute or process gas by controlling compressors to maintain specified pressures on main pipelines. There are over 5,000 of these workers in Pipeline Transportation. You will find this worker operating plant equipment, monitoring flammable products, and controlling compressors. Job titlees for this worker are Gas Controller and Plant Operator.

Employment of Gas Plant Operators

Lubricates machines, changes parts, and performs machinery maintenance. Pipeline Transportation employs a little over 7,200 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

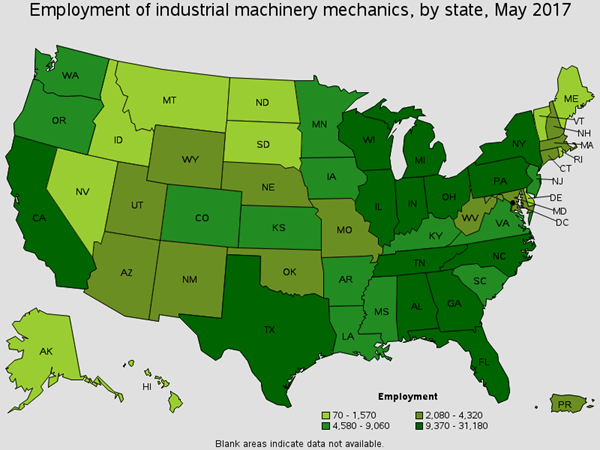

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 3,100 of this occupation working in Pipeline Transportation. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Employment of Industrial Machinery Mechanics

Help move materials across operations. There are around 3,400 of these workers in Pipeline Transportation. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

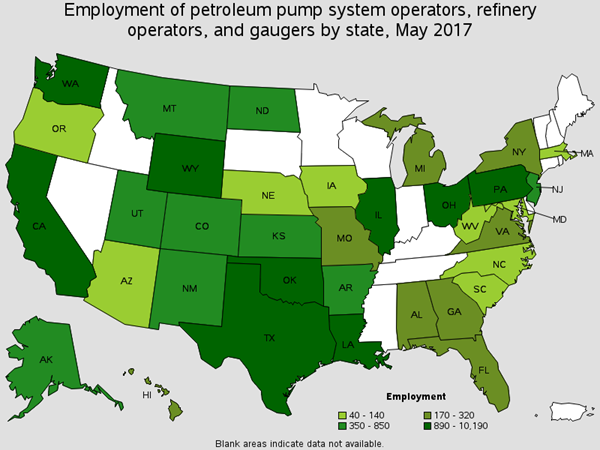

Operate petroleum refining or processing units. There are around 6,300 of these workers in Pipeline Transportation. You will find these workers monitoring gauges, opening valves to regualte the flow of oil, and operating manifold/pumping systems. Common Job titles for this position are Gauger, Head Operator, Pumper, and Refinery Operator

Employment of Petroleum Pump System Operators

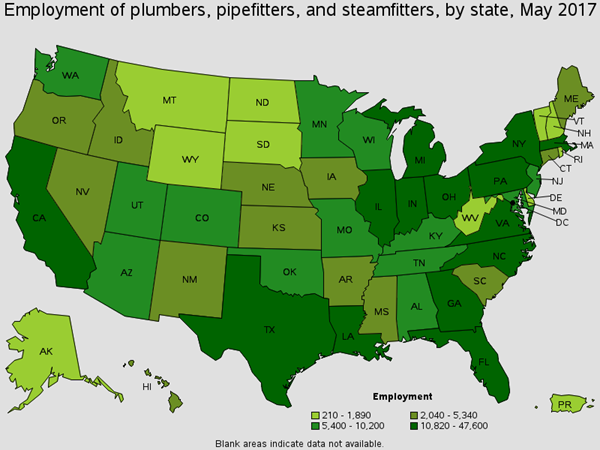

Assemble, install, alter, and repair pipelines. There around 1,700 of these workers in Pipeline Transportation. You will find these workers hammering pipes, securing pipes, and cutting piples. Common job titles for this position are Pipe Fitter, Pipe Welder, and Steamfitter.

Employment of Pipelayers, Plumbers, Pipefitters, and Steamfitters

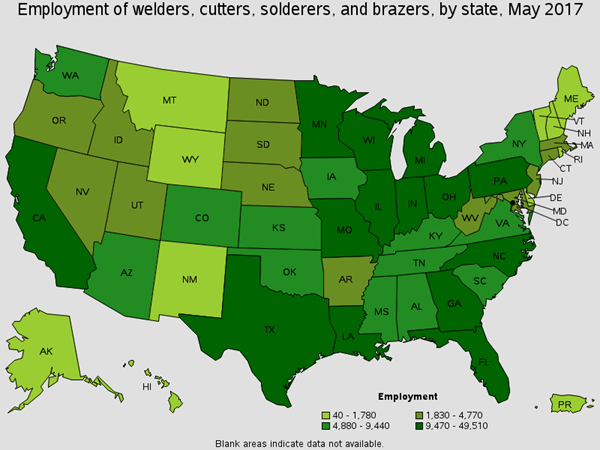

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 280 of these workers employed in Pipeline Transportation. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

Employment of Welders, Cutters, Solderers, and Brazers

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. Pipeline Transportation employs around 290 of these workers. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Safety is the number one priority on any pipeline job site, as there are endless worksite hazards. Numerous activities pose a risk, from welding pipes, cleaning pipes and falling objects.

The Pipeline industry ranks as the second most hazardous Oil and Gas sub-industry, when compared to the Oil Extraction sub-industry and Refineries sub-industry. Thankfully, though, the incidents per 100 employees are much lower than other industrial industries. This is a testament to the value placed on working safely across pipeline worksites.

"When you gamble with safety, you bet your life.""

Gambling may be fun for those spending a weekend in Las Vegas. For those that may lose their eyesight constructing pipelines, gambling is not an option and is not fun for those that find themselves in a hospital with an injured eye. Do not gamble by wearing inappropriate PPE!

At MCR Safety, We Protect People! Let us help you find the appropriate PPE for the hazards you face!

Find the right MCR Safety product that protects you against these common hazards.

Workers transport many materials and move a lot of drums constructing pipelines. Heavy-duty wearing gloves are all these workers require!

Learn More About Abrasive Handling ProtectionCommon Applications:

Pipeline maintenance requires spraying chemicals. Our MG9648 is so lightweight; workers will not even know they are wearing gloves.

Learn More About Applying Herbicides and Pesticides ProtectionCommon Applications:

Hand removal of these materials requires gloves, aprons, and goggles.

Common Applications:

.png?h=272&iar=0&mw=600&w=600&hash=7DE9893E502CE2EF5054352B2C9F54BB)

Chemicals are an everyday concern for Oil and Gas workers meaning workers need full protection. Our chemical protection page is a good place to start.

Learn More About Chemicals ProtectionCommon Applications:

56% of all recordable Oil & Gas incidents in 2014 were attributed to "struck by" and "caught between” objects. Simply put, oil and gas work will quickly bang up a worker’s back-of-hands. Are you ready for the new impact standard?

Learn More About Crush and Impact ProtectionCommon Applications:

Mainline and station piping requires welding gear at times. Tie-in crews have no problem making the final welds at junctures and joining metal components on a pipeline. They only require wearing MCR Safety welding gear!

Learn More About Cutting and Welding ProtectionCommon Applications:

Midstream work generates some dusty conditions! Lined eyewear styles are the ticket!

Learn More About Dust ProtectionCommon Applications:

Midstream workers must wear FR gear at all times. Max Comfort FR gear protects workers from all too common Flash Fires.

Learn More About Fire and Explosion ProtectionCommon Applications:

Pipeline work in the hot sun can take a toll on workers. Breathable safety gear is necessary when temperatures escalate. We’ve got you covered with premier breathable PPE.

Learn More About Heat Stress ProtectionCommon Applications:

Form-fitting eyewear is essential gear for workers when flying debris and fragments are in the air. Check out our eyewear protection page.

Learn More About Impaired Vision ProtectionCommon Applications:

Staying FR compliant in the rain and around liquids has always been a challenge. Not anymore! Big Jake rainwear protects workers from ARC flash hazards!

Learn More About Inclement Weather and FR ProtectionCommon Applications:

You are going to need steel toed boots when working around the presence of water, chemical hazards, and falling objects.

Common Applications:

You need excellent gear when gripping in and around oily surfaces. BNF gear provides ultimate grip in this environment.

Learn More About Oils, Lubricants and Greases Protection

Any time machinery is transmitting energy, protecting your fingers deserves real attention. Are you ready for the new impact standard?

Learn More About Pinch Points ProtectionCommon Applications:

Launching a pig scraper to clean and maintain pipes exposes workers to benzene, toluene, and xylenes. Neoprene, Butyl, and PVC gloves are this worker’s best friend.

Learn More About Pigging Protection

Midstream workers know pipes are a part of the trade. They only demand high quality protection when working around pipes. MCR Safety has been manufacturing leather gloves for many years. Check out some of our latest innovations.

Learn More About Pipe Maintenance ProtectionCommon Applications:

Midstream workers are always exposed to sharp metal. Cuts and lacerations make up 7 percent of all oil and gas injury claims. Rest assured, we simplify the selection process on our cut protection page.

Learn More About Sharp Objects ProtectionCommon Applications:

Handling contaminated materials requires premium chemical gloves, goggles, FR rain suits, and full-face shields.

Learn More About Spill Response ProtectionCommon Applications:

Moving and removing soil with pressured water requires face shields, goggles and some nice leather gloves.

Common Applications:

Working in low light and high traffic areas means workers need to be seen! Hi-Viz garments distinguish the worker and keeps them seen!

Learn More About Visibility ProtectionCommon Applications:

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.