Cut Protection Overview: Materials, Industries, and Applications

We know finding the right safety gear is important to you, otherwise you would not be visiting the MCR Safety website. For those working around extreme hazards, where cut and puncture injuries are likely to occur, finding the right PPE is highly important. Workers dread encountering sharp blades, objects, and edges. These type hazards can easily cause lacerations, slashes and nicks. With over 143,000 hand injuries reported in 2015 by the Bureau of Labor Statistics, you cannot afford to be wearing the wrong safety gear, definitely when encountering these hazards.

Even with so many injuries present, OSHA still reports that 70% of workers are not wearing protective gloves. We know you are not one of these workers! In fact, we know you want to wear the correct safety gear. Well, you have come to the right source. MCR Safety manufactures a complete lineup of high performance cut protection products, from gloves to sleeves.

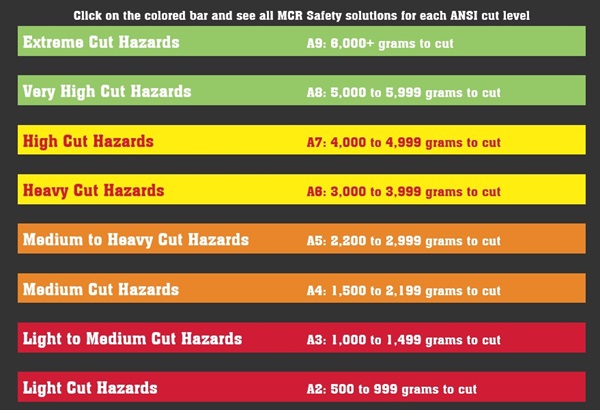

Cut Protection Search by ANSI Score

Just click on the colored heading below for the desired cut level

and we'll show you every solution we've got.

To help simplify your life even further, we have also designed a tool to help you find the most appropriate cut resistant, along with puncture resistant gloves:

https://www.mcrsafety.com/resources/mobile/search-cut-score

By using this tool, you are one-step toward selecting the right glove with the optimal cut and puncture levels.

ANSI/ISEA Cut Levels

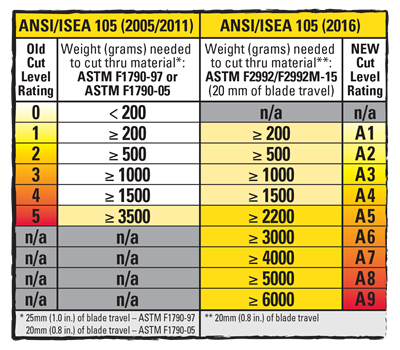

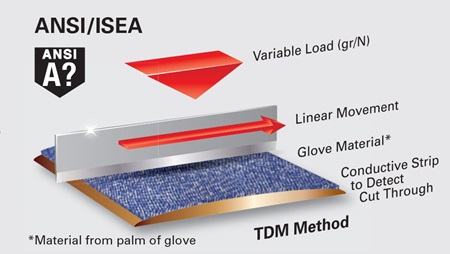

The American National Standards Institute’s ANSI/ISEA 105-2016 cut resistance standard uses a nine (9) level scale. This easily helps users identify and zone in on the cut resistant glove and sleeve required for the specific hazard faced. The level of cut resistance extends from 0 to 6,000 grams, based on tests by a Tomodynamometer (TDM Method), which moves a blade across the material. The higher the weight required to cut the materials the higher the cut resistance rating. A higher rating provides the wearer with better protection and cut performance. Be sure to download our PDFs found below, which provides more in-depth knowledge.

The American National Standards Institute’s ANSI/ISEA 105-2016 cut resistance standard uses a nine (9) level scale. This easily helps users identify and zone in on the cut resistant glove and sleeve required for the specific hazard faced. The level of cut resistance extends from 0 to 6,000 grams, based on tests by a Tomodynamometer (TDM Method), which moves a blade across the material. The higher the weight required to cut the materials the higher the cut resistance rating. A higher rating provides the wearer with better protection and cut performance. Be sure to download our PDFs found below, which provides more in-depth knowledge.

Diagram for the ANSI/ISEA testing process with a Tomodynamometer (TDM Method)

Click on the colored bar and see all MCR Safety solutions for each ANSI cut level

Different materials provide different levels of cut protection. The right balance between protection and comfort is key to staying safe on the job and ensuring you will want to wear the gear.

Below is a good general guideline when considering cut resistant materials.

General Guide to Cut Resistant Materials and Technologies

| Material |

Cut Resistance |

Abrasion Resistance |

Heat Resistance |

Dexterity |

MCR Style |

|---|---|---|---|---|---|

| Kevlar® |

|

|

|

|

9375 |

| Kevlar® / Steel Blend |

|

|

|

|

9399 Armor Tech |

|

Dyneema® Diamond Tech |

|

|

- |

|

9676 |

|

Dyneema® Diamond Tech / Steel Blend |

|

|

- |

|

9672DT5PU |

| Alycore® |

|

|

- |

|

PD2905A |

|

Spectra/Fiber Glass Reinforced |

|

|

- |

|

9346D "Memphis Survivor" |

|

Steelcore® II Synthetic/Steel blend |

|

|

- |

|

9356 "Steelcore® II" |

| Key | Performance |

|---|---|

|

|

Extreme Cut Protection |

|

|

Excellent |

|

|

Very Good |

|

|

Good |

|

|

Average |

| - | Not Recommended |

The above guide should be used only as a general reference point. Always keep in mind that each technology allows us to manufacturer cut resistant gloves and sleeves, not cut proof. You will find a lot more information for the specific cut resistant technologies in each dedicated feature page.

Industries - Cut Dangers Lurks Everywhere

Cuts and lacerations occur at a rate of 8.1 incidents for every 10,000 workers. If you’re a worker, chances are good that either you or one of your co-workers will be cut at some point. If you’re an employer, it’s almost guaranteed that you will be shelling out money for lost productivity and health care costs sooner or later. Therefore, it only makes sense to provide appropriate PPE on the front end, to both protect your workers and to potentially save on indirect costs associated with injury.

Many industries have at least some level of hazard from cuts and lacerations, but workers in accommodation and food services, construction, retail trade, manufacturing, and utilities face elevated cut and laceration risks. See the table below.

| Industry | Cases of Cuts and Lacerations | Total Number of Nonfatal Injuries |

|---|---|---|

| Accommodation and Food Services | 18.2 | 78,560 |

| Construction | 17.9 | 79,890 |

| Retail Trade | 11.5 | 123,770 |

| Manufacturing | 10.9 | 122,610 |

| Utilities | 7.2 | 90,990 |

Top Industries with Cut Injuries

One surprising trend is that cuts and lacerations are now more common in the retail trades than in manufacturing, and the injury numbers there are rising. Opening boxes and handling box cutters is an application that many workers forget can easily cause dangerous cuts.

N9690TC protecting a worker’s hand from a box cutter.

Most Dangerous Occupations by Incident Rate

.png)

Perhaps not surprisingly, food preparation positions claim the #1 spot on the top 20 list of cut and laceration injuries by occupation. By the numbers, food is more dangerous to work with than sheet metal.

Here are the top 20 occupations with the highest cut, laceration, and puncture incident rates, as reported by the BLS:

| Occupation | Incident Rates (Per 10,000 workers) | |

|---|---|---|

| Cuts, Lacerations, and Punctures | Total Incidence Rate | |

| Food Preparation Workers | 94.5 | 290.8 |

| Sheet Metal Workers | 86.5 | 289.9 |

| Installers | 56.8 | 319.5 |

| Dishwashers | 53.4 | 145.6 |

| Construction Laborers | 46.1 | 265.3 |

| Chefs and Head Cooks | 39.5 | 182.7 |

| Food Servers, Non-Restaurant | 34.5 | 201 |

| Automotive Service Technicians and Mechanics | 34 | 207.2 |

| Maintenance and Repair Workers, General | 31.6 | 262.4 |

| Laborers and Freight, Stock, and Material Movers by Hand | 30.9 | 297.8 |

| Dining Room and Cafeteria Attendants and Bartender Helpers | 30.3 | 151.4 |

| Police and Sheriff Patrol Officers | 28.6 | 497.7 |

| Correctional Officers and Jailers | 28.3 | 420.2 |

| Welders, Cutters, Solderers, and Brazers | 28.3 | 163.9 |

| Painters, Construction and Maintenance Workers | 28.1 | 235.9 |

| Cooks, Institution and Cafeteria | 26.2 | 184.9 |

| Plumbers, Pipefitters, and Steamfitters | 26 | 193.7 |

| Landscaping and Groundskeeping Workers | 25.7 | 194.1 |

| Bus and Truck Mechanics and Diesel Engine Specialists | 24.6 | 246 |

| Janitors and Cleaners, Except Maids and Housekeeping Cleaners | 20 | 277.4 |

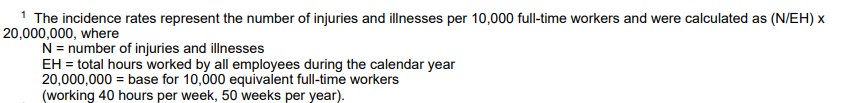

Here is how the BLS computes the total incident rate:

Cut Injury Sources

We highlighted the primary sources of puncture injuries, applications, and events in our Top ANSI Puncture Resistant blog. Cut injuries occur from many of the same incidents; however, there are some sources that cause more cuts than punctures. The BLS reports the following as the main sources in 2017 where cut injuries occurred:

- Tools, instruments, and equipment – 29,680 injuries

Construction tools can quickly lacerate a worker’s hand.

- Hand tools – 19,430 injuries

- Parts and materials – 14,770 injuries

- Machinery – 12,650 injuries

- Knives – 11,010 injuries

Not listed in our puncture blog, mostly sources of cut injuries:

- Containers, furniture, and fixtures – 9,030 injuries

- Structures and surfaces – 6,320 injuries

- Box cutters and razor knives – 5,440 injuries

- Vehicles – 4,420 injuries

- Metal and woodworking – 3,520 injuries

- Food slicers – 3,050 injuries

- Structural metal materials – 3,030 injuries

Structural metal is always a cut concern. 1400K (shown here) is lined with DuPont™ Kevlar®.

Events Causing Injuries

Below are the top events that cause cuts and lacerations in the above occupations:

-

Contact with objects and equipment – 66,030 injuries

There are many variations of this injury that occur: workers struck by equipment or an object, workers struck against an object or equipment, falling equipment, slipped object, swinging object, object breaking in hand, workers caught in running equipment, etc. - Falls, slips, and trips – 5,240 injuries

- Transportation incidents – 1,070 injuries

Any metal object or equipment will quickly lacerate a worker’s hands.

Applications Where Cut Protection Is Required

| Aircraft Assembly | Handling aluminum strips | Oily metal part handling |

| Automotive assembly | Handling cables and wires | Plate glass handling |

| Bending, pressing, punching, and shaping metal | Handling mold plates | Power tool handling - drill, nail, and screw gun |

| Carpet knife and installation | Handling plumbing valves | Precision mechanics |

| Circuit board work | Heavy metal stamping | Presswork and metal handling |

| Component aligning and handling | HVAC sheet metal handling | Pulling lines |

| Cutting ductwork and sheet metals | Installing ceramic tiles | Razor knife handling |

| Cutting pipe | Installing electrical boxes | Sharp steel handling |

| Cutting tool operating | Light fixture installation | Sheet metal assembly |

| Deburring | Light metal assembly | Small parts handling w/ sharp edges |

| Delicate metal handling | Light metal fabrication | Solar panel installation |

| Drywalling | Light metal handling | Sub-assembly work |

| Electronics assembly | Light metal stamping | Tree cutting |

| Fastening and wiring | Maintenance repair | Untrimmed parts handling |

| Fisheries and handling fish | Manufacturing appliances | Warehouse receiving / shipping |

| Food canning and bottling | Metal ceiling frame work | Waterproof piping |

| Glass handling and installation | Metal stamping | Window frame installation |

| Grinding and filing | Metal stud framing | Working around sharp edges |

| Moving metal work pieces | Utility knife handling |

Sheet Metal Industry Page

Sheet metal is ranked #2 on the list above. We have an entire industry page dedicated to this type of work. Just click the image to learn more about the protection this worker will require.

Additional Information

Additional Information about Cut Protection

Cut Protection Focused Industry-Leading Technology

Learn more about the technologies that fuel the fire behind our industry leading protective gear!

The cut resistant technologies we utilize are Alycore, DSM™ Dyneema®, and Dupont™ Kevlar®, Spectra Fibre, and Steelcore stainless shell. Each technology offers unique advantages, designed for keeping you safe across multiple industries and work environments. Some of these include: Automotive, Construction, Food Preparation and Processing, Manufacturing, Metal Fabrication, Metal Stamping, Oil & Gas, Recycling and Waste Management. Each of these industries have applications where different cut resistant technologies are needed and where these technologies perform best, which is why we utilize so many. When performance matters most, when you want to take protection to the next level, look to MCR Safety’s cut resistant products!

Alycore®

Dyneema®

DuPont™ Kevlar®

Cut & Slice Protection from Our Blog

Want more info for gash, laceration, chop and any other types of cut protection? Check out our latest articles from our blog.

Latest Products that Feature Cut Protection

WARNING: THESE PRODUCTS ARE CUT RESISTANT, NOT CUT PROOF. DO NOT USE WITH OR AROUND MOVING EQUIPMENT, TOOLS OR MATERIAL.