Wouldn't it be nice if the definitions for all FR terminology we use were in

one spot? Here they are!

used to define an FR garment that can be worn year-round.

a type of electric explosion from a voltage breakdown of the resistance of

air. More on this subject here.

values that indicate the ARC performance of the material. The number is

stated in cal/cm².

PPE that protects from arc flashes and electric arc hazards. ARC-rated

garments are measured in cal/cm². More on this subject here.

a chemical family of FR fibers like Nomex® (meta-aramid) and Kevlar®

(para-aramid).

is what ARC-rated protection in fabrics measures. It creates the maximum

performance capability for a specific FR garment or fabric and is shown in

cal/cm².

FR clothing worn beneath primary FR clothing for added safety.

the formation of holes in the fabric during ARC rating testing. This is

the point of failure of FR protective garments as those holes allow heat

or flames to pass through. This deterioration of a flame-resistant fabric,

caused by breakopen, is measured as cal/cm² and is expressed as EBT rather

than ATPV.

a measurement used for FR clothing performance founded on the amount of

damaged fabric when ASTDM 6413 is performed. Hook and loop - a broad term

for what is commonly referred to as VELCRO® brand fasteners. These hook

fabrics adhere to the loops to create a strong bond.

a substitute measure to ATPV. Energy Breakopen Threshold (EBT) is reported

when ATPV cannot be measured due to FR fabric breakopen.

a fabric or material that burns slowly or self-extinguishes. Unlike

synthetic polyester materials, FR materials don't fuel a flash fire.

flame-resistant clothing.

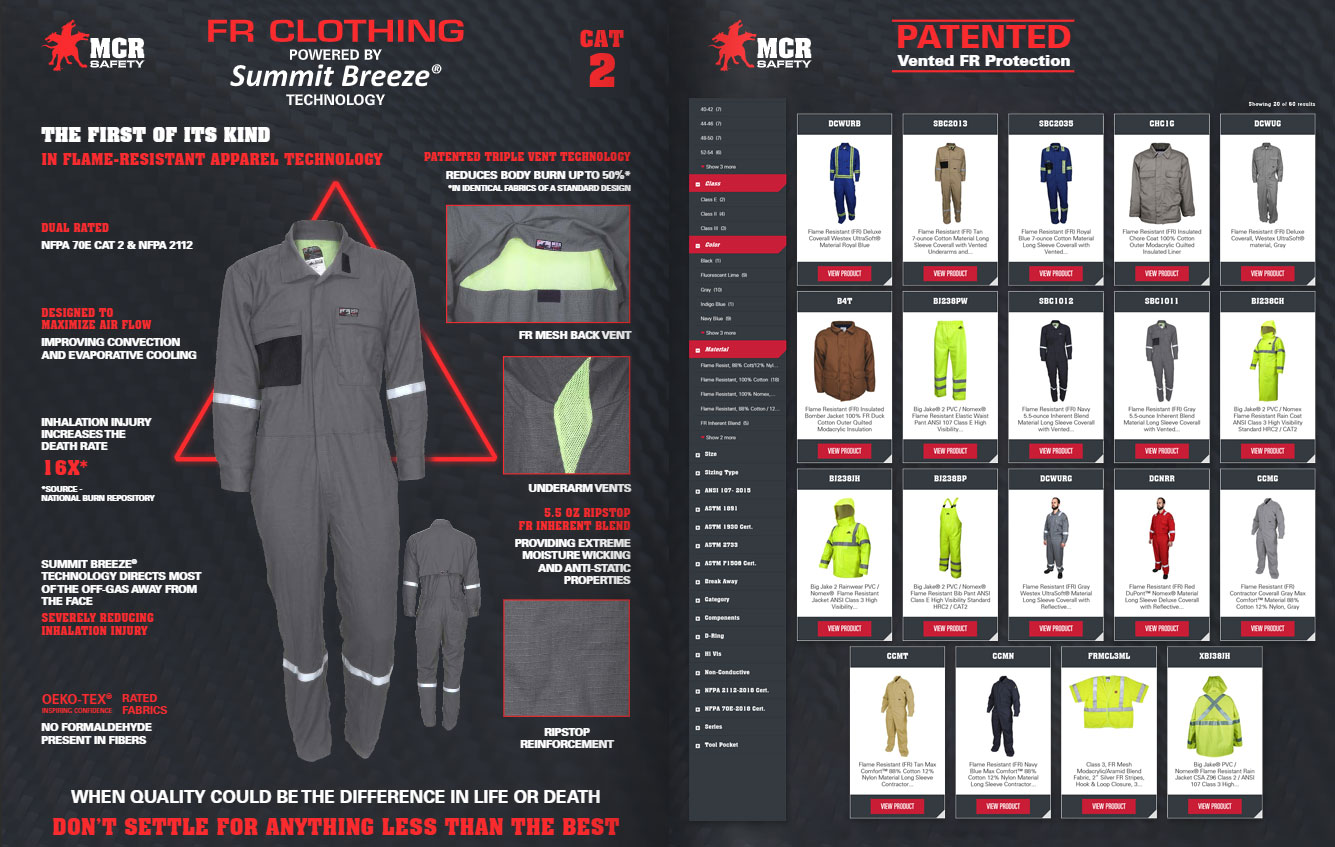

OSHA states that heat stress can cause illness and death. The most serious

heat illness is heat stroke, followed by heat exhaustion. Lightweight,

breathable fabrics can help reduce heat stress. Summit Breeze® technology

provides ultimate breathability with vented heat stress management.

defined by NFPA 70E and based on the risk associated with electrical and

arc flash hazards. It governs the appropriate ATPV of flame-resistant

clothing. In 2015, the terminology was changed from HRC levels to PPE

levels.

have an ARC rating between 8 cal/cm² and 25 cal/cm².

have an ARC rating between 25 cal/cm² and 40 cal/cm².

have an ARC rating equal to or greater than 40 cal/cm². High ARC ratings

are achieved with multiple FR layers and liners, such as those found in

insulated outerwear.

FR fabric made of FR fibers that do not require additional chemical

treatment to achieve flame resistance. More found on this definition here.

National Fire Protection Association. More on this organization here.

a simulated flash fire test using an instrumented manikin to gauge the

assessed percentage of second- and third-degree body burns after three

seconds of contact.

fabrics that transfer sweat away from the body and allows it to dry

quickly. This keeps a wearer cooler, drier, and more comfortable.

National Electrical Safety Code.

FR clothing designed for wear during activities where a worker is

constantly exposed to flame, radiant heat, or molten metal splash.

FR clothing designed for intermittent hazards.

total body surface area (%TBSA) that is affected by a burn.

a fabric's TPP is determined by the amount of heat it takes to pass

through the fabric and cause a second-degree burn.

fabrics where chemicals are added to the fabric to achieve flame

resistance. More found on this definition here.

this is a standard test method for measuring the flame, also commonly

referred to as ASTM D6413.