MCR Safety is the first company to offer safety glasses that have been UV cured, improving both anti-fog performance and durability. The anti-fog technology, shortened to UV-AF, describes the very essence of the coating itself, making it easier for users to remember and to more easily identify UV cured safety glasses. This technology is now available in our Checklite and Bearkat styles.

You’re probably familiar with one of the above examples where UV light is utilized.

Sometimes, UV light gets a bad rap, since people must block out the sun’s harmful UV lights wherever possible. This includes your eyes, which all MCR safety glasses provide 99.9% UV light protection. However, things that are bad in one area, can be harnessed for good in another, example being UV cured AF safety glasses.

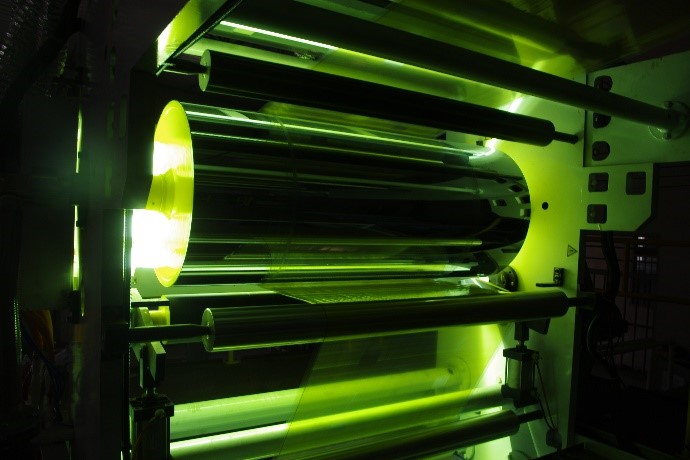

Example of UV curing taking place in a plastic manufacturing operation.

For proprietary reasons, we have elected to not show images of our new UV-Curing eyewear factory operations. Instead, the above image shows a UV curing operation in place across other manufacturing industries. It’s now used in manufacturing safety glasses!

Applying UV curing anti-fog coating to safety glasses improves performance by 3X when compared to standard anti-fog coated styles. In addition to better anti-fog performance, UV-AF anti-fog coating provides extended durability. Standard AF will start degrading immediately after the first cleaning. With UV-AF coated safety glasses, degrading will not take place for six to seven months after the first cleaning.

In addition, UV-AF is an environmentally superior product. This is because UV-AF anti-fog glasses require no lengthy thermal curing, instead using ambient temperatures to instantly UV cure the safety glasses.

UV-AF coatings are environmentally friendly when compared to standard AF coatings. MCR Safety is the first to offer this type of anti-fog safety glasses. We led the way with Max 6 coatings, now numerous companies have followed our lead with Max 6. We expect UV-AF coating will become the norm for all safety glass companies in the years to come.

Here is how this product is eco-friendly:

Less Electricity

87% less energy required as compared to standard AF applications.

Fewer Chemicals Used

Less pollution is being released into the eco-system.

Fewer CO2 Emissions

A savings of roughly 13,000 kg of CO2 per month.

Whenever you see this stamp on the lens, you’ll know you’re wearing UV-AF anti-fog lenses.

Over the next five years, MCR Safety plans to completely replace our standard anti-fog styles with UV-AF. It is our commitment to offer PPE users can trust while manufacturing products that are geared towards reducing CO2.

Better anti-fog product, at the same cost, and with less C02 emissions. Why would you continue purchasing any other companies' standard AF styles? We can’t think of one reason. Give us a call today to find a distributor in your area.

For more environmentally friendly products from MCR Safety, be sure to check out our NXG Intelligent Manufacturing page.