Any MCR Safety glove emblazoned with the Ninja® logo guarantees the highest level of innovation and hand protection technology available. Our Ninja® line uses the newest applications, coatings, and materials to create reliable hand protection. We combine a high-quality shell with polymer material to give users the protection and comfortable grip they require on the job. Similar to sports and fashion gloves, our Ninja® series is more attractive and user-friendly than traditional hand protection options. Each glove is sleek, stylish, and comfortable! Additionally, we equip Ninja® gloves with the most advanced features, which entices wearers to keep their gloves on and reduces risk of injury.

Ninja® is a glove brand sold exclusively by MCR Safety across The United States and Canada

Actifresh® is an antimicrobial agent that kills bacteria and promotes freshness, extending the life of the glove.

Combing polymers leverages the strength of each individual polymer to create a stronger barrier of protection. The strength of nitrile combined with polyurethane’s (PU’s) tactility creates one tough glove without sacrificing sense-of-touch.

This material provides greater comfort and longer wear due to its excellent breathability which allows the glove to better dissipate body heat.

Our first ever impact- and liquid-resistant glove is a Ninja® product.

This PVC-based coating repels water, making it perfect for wet and winter conditions!

Our lightest weight glove is found in our Ninja® series. It weighs in as 30% lighter compared to standard PU gloves.

We reinforce critical wear areas, including the thumb crotch.

This packaging approach means you’ll be able to find these gloves everywhere, from vending machines to industrial showrooms.

Nitrile BNF provides superior grip! Don’t believe us? Check out the video below that showcases Nitrile BNF's greater grip versus the other guys.

Here is a general breakdown of polymers commonly used for gripping in various working conditions and their grip scores:

|

|

Oil | Acids | Water | Abrasion | Dry |

|---|---|---|---|---|---|

| Max Grid Fabric | 5 | 1 | 5 | 4 | 5 |

| Nitrile | 4 | 4 | 4 | 4 | 4 |

| PU | 1 | 1 | 4 | 3 | 4 |

| Latex | 0 | 1 | 5 | 5 | 5 |

| PVC | 3 | 3 | 3 | 3 | 3 |

| Neoprene | 5 | 4 | 4 | 2 | 4 |

Not all workplace applications require cut-resistance. However, workers still need solid protection from many everyday environments. In total, there were over 143,000 hand injuries in 2015, and many of these could have been prevented with proper hand protection.

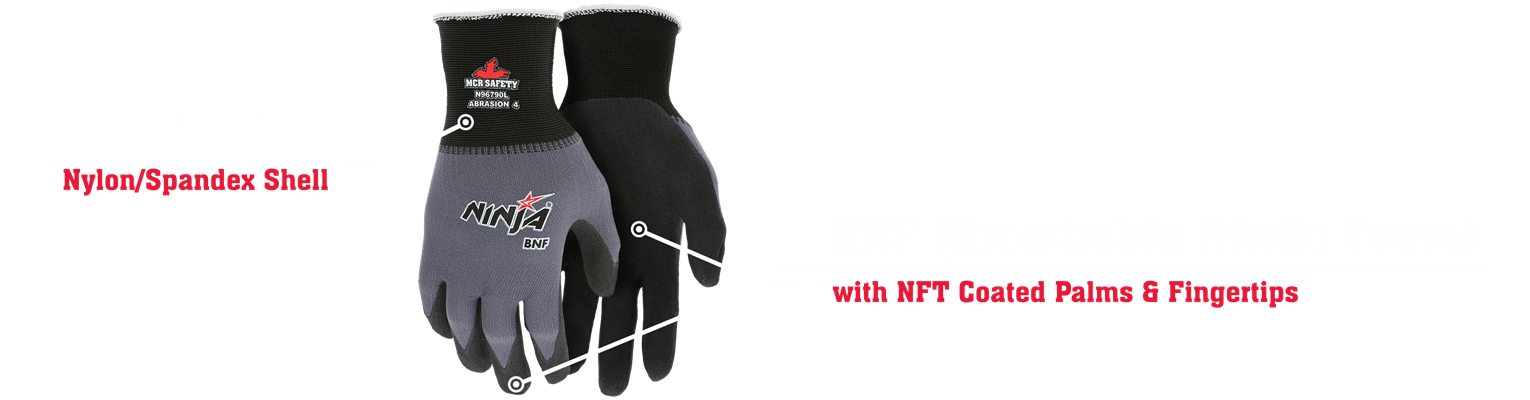

General purpose Ninja® gloves provide protection from the all-too-common abrasion injury and offer excellent dexterity with their form-fitting style! From gardening to construction work to manufacturing assembly work, Ninja® gloves protect the hands of countless people every day!

Below is a breakdown of the Ninja® glove styles MCR Safety offers.

The elasticity and flexible nature of latex provides remarkable gripping power. Our Ninja® crinkle-dipped latex glove provides excellent grip and is coated on a super lightweight 15-gauge nylon shell.

Looking for the perfect balance between PU and nitrile? We admit, some

applications require a little more strength than the standard PU coating

provides. At MCR Safety, we’ve got you covered with our bi-polymer

coatings!

Polyurethane is an incredibly resilient, flexible, and durable polymer. Users will find astonishingly sensitive sense of touch along with high abrasion resistance when utilizing a PU dipped glove. Combine the PU coating with an 18-gauge shell and you’ve got one lightweight, abrasion-resistant glove. The N9696 Ninja® Lite is a featherweight PU option many utilize for all-day comfort and precise grip. This glove is approximately 30% lighter than traditional nylon/polyurethane gloves and provides unparalleled tactile sensitivity.

Here is a breakdown of the different gauges, just so you know how 18-gauge compares to the others:

Eighteen stitches knitted per inch, featherweight styles

Fifteen stitches knitted per inch, ultra-lightweight styles

Thirteen stitches knitted per inch, lightweight styles

Ten stitches knitted per inch, medium-weight styles

Seven stitches knitted per inch, heavy-weight styles

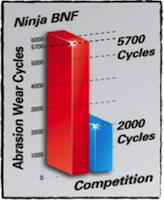

An abrasion-resistant glove is extremely important for safety, comfort, and longevity. Our Ninja® BNF has exceptional abrasion resistance and unparalleled grip performance. Internal testing shows BNF offers 30% better abrasion resistance than standard nitrile.

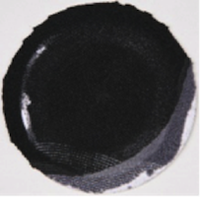

Here is a look at some abrasion testing we conducted on our Ninja® BNF coating:

Competitor at 2,000 cycles

BNF at 2,000 cycles

BNF at 5,700 Cycles

BNF overall visual aid

The more cycles, the more abrasion resistance has occurred. At 5,700 cycles, BNF holds up better than a competitor’s option at 2,000 cycles. You can see how seriously we take protecting people’s hands by our rigorous and thorough product testing. This is important because the longer a glove’s coating stays intact, the longer the wearer will be able to safely grip without replacing the glove.

Excellent tactile sensitivity, combined with excellent longevity and abrasian resistance

As we point out in the following blog, workers won’t wear gloves that make their jobs harder. This is especially true if they can’t easily feel what they’re touching. When dexterity or sense of touch is compromised, the gloves are coming off - literally. At MCR Safety, we believe that the only way to foster better PPE habits is to provide better PPE equipment. With MCR Safety’s 18G Featherweight BNF gloves, users will want to wear their glove all-day long due to the glove’s breathable comfort. Here are the 18-gauge BNF styles we offer:

Ultralightweight breathable glove, with excellent abrasian resistance and great dexterity

Our 15G lineup of Ninja® BNF is our most popular! It strikes the perfect balance between the 18-gauge and 13-gauge gloves. You will find this lineup of gloves worn by workers in virtually every industry due to their comfortable lining and breathable coating. Here are the 15-gauge BNF styles we offer:

Super thin oil repellant coating

Our HPT Ninja® styles, are designed for winter conditions. However, Mother Nature can quickly turn sunny conditions into rainy ones in no time, especially during summer months. For this reason, the level of water resistance a glove offers should be a buying factor for those working around wet objects or in damp conditions and want to keep their hands safe and dry. Check out below the specs to our HPT style:

Gloves Designed for the Coldest Winter Months

When working outside during the winter months, cold hands can be problematic. Not only can cold, stiff hands be hazardous to one’s own personal safety, they can also slow workers down. Worker performance during the challenging winter season requires high-quality PPE solutions. This is where our Ninja® winter gloves enter the picture. Watch the short Ninja® Ice glove video below to learn more!

Provides users with a water repellant coating

Our HPT coating creates encapsulated air molecules, which repel liquids for an unprecedented firm grip, either wet or dry. Weather conditions can change quickly and for this reason, a glove’s level of water resistance should be a buying factor for those working around wet objects and for keeping hands dry in damp work environments. Here are the Ninja® ICE® glove styles we offer:

N9690

Bright colors allow for worker recognition

When it’s a cloudy, snowy day, visibility can be a challenge and noticing workers can be difficult. Any extra detection opportunity can mean the difference between an injury and someone going home unharmed. Here are the Hi-Vis Ninja® ICE® glove styles we offer:

N9690FCO Orange Hi-Vis Color

N9690HV keeping a worker’s hands warm at work

These gloves provide users with TPR impact level 1 protection along with chemical, liquid, and oil protection.

Many objects may bump up against a worker’s hands during maintenance and industrial activities. Impact protection is a worker’s best friend. It doesn’t hurt having some chemical protection, too! Check out below the specs to our Ninja® Alchemy impact glove.

N2658HVO protects countless workers across the oil and gas industry