The next generation of gloves requires the next generation in manufacturing. MCR Safety’s brand new state-of-the-art manufacturing facility opened in 2019. Under the NXG brand, our new manufacturing facility produces premium gloves with advanced coatings, utilizes 21st-century manufacturing efficiencies, and does so with environmentally friendly production methods.

We highlight everything you need to know about NXG branded gloves below, along with a look back at MCR Safety’s progression over the years in becoming your go-to manufacturer for safety work gloves.

The best way to visualize what NXG means is by remembering three words: Product, Process, and Planet. We explore each one of these separately below. We hope by the time you’ve finished reading, you will be ready to try out MCR Safety’s next generation of gloves and feel confident in the product, its manufacturing process, and the impact our production has on the planet.

Product

Workers demand premium PPE products on the job-site. Without them, employees wind up working a shift uncomfortable and less protected than they should be. From a company’s standpoint, it only makes sense to outfit workers with gloves that fit, are comfortable, and last. Here are all the upgrades you can expect from NXG branded gloves:

Features of NXG-Branded Gloves

Product Purity

All NXG gloves are manufactured in 100% enclosed environments, ensuring only the highest quality output.

7-Step Product Cleansing

Ensures gloves smell fresh, with no strong chemical odors attached.

Increased Longevity

Due to our new and improved proprietary dipping processes, coatings are more advanced than ever before.

Multiple Quality Checks

There are quality checkpoints at multiple workstations to ensure high-quality output.

Polymer Adhesion

Second to none as a result of our proprietary shell-drying techniques.

ANSI Testing

Our NXG factory will mirror the current U.S. ITC lab.

A second ANSI 105 testing lab has been installed at the facility, ensuring the same quality testing is performed at the factory and our U.S. ITC Lab. MCR Safety’s Innovations Technology Center (ITC Lab) went live in 2010, testing PPE for cut-, abrasion-, heat-, puncture-, impact-, and tear-resistance. In July of 2016, our commitment to excellence led to the ITC becoming one of the first North American testing labs to receive ISO/IEC 17025 accreditation for Hand Protection, an international standard that requires companies to demonstrate a high degree of accuracy and consistency in testing protective equipment.

MCR Safety is committed to protecting people, and it all starts with the product made. When you see the NXG brand, we want you to know you’re wearing the highest quality glove available on the market. Don’t take our word for it, try them out yourself!

Process

A strategy may be the road map of a business, but it is operational efficiency that drives the actual vehicle to the end customer. A business lacking fundamental efficiencies in its processes will eventually have longer delivery times and offer inconsistent quality in its services. Quality, consistency, and efficiency are the forces that go a long way in exceeding customer satisfaction levels.

Advances in technology have allowed us to adopt cutting-edge manufacturing efficiencies and automate numerous operational processes. Here are a couple of the updated processes found at our new manufacturing facility:

Production Efficiencies

We've streamlined our dipping machines, resulting in faster glove dipping and faster production.

Packaging Automation

We've leveraged the latest technology to automatically roll and seal gloves, as well as fill glove case packs.

All glove dipping occurs in a 100% enclosed manufacturing environment.

Operational efficiency and exceptional processes are paramount for any business to function, much less survive, in the 21st century. Companies that are not focused on reducing waste and consuming fewer resources will likely not remain in business for very long.

At MCR Safety, we’ve invested in the latest manufacturing equipment, ensuring increased glove production that relies on fewer resources, utilizes automation, and reduces overall waste. Without these enhancements, our next point is in no way achievable.

Planet

MCR Safety is committed to protecting workers’ hands and to protecting the planet. We recognize that being a manufacturer comes with a big responsibility, as we engage in activities that consume many resources and our decisions impact generations to come.

For some time now, global environmental sustainability has been at the core of how MCR Safety has done business. From offering recycled PVC in our gloves and garments to developing products made with sustainable bamboo materials, we are working to reduce our carbon footprint and not waste valuable resources. That is why we are building modern distribution facilities that use less energy and purchasing new eyewear equipment that reduces CO2 transmissions; we know the world is counting on us to make thoughtful decisions.

So, when it came time to outline the manufacturing components of our new operation, sustainability was at the forefront of planning the new factory’s design and operations. MCR Safety’s intelligent-design manufacturing is committed to sustainability in three distinct ways:

Zero Contamination of the Environment

Achieved by incorporating premier water treatment and filtration systems.

Exhaust Gas Cleaning

Gloves manufactured under the NXG brand ensure less gas is released into the ecosystem due to improved air filtering processes.

Clean Energy Utilization

Our new factory relies less on electricity generated by coal, natural gas, and petroleum and more on alternative energy sources like sustainable solar and wind energy.

MCR Safety Manufacturing

"Trusted to Protect"

Since 1974

MCR Safety has over forty-five years of experience as a leader in the field of personal protective equipment (PPE). Our wide variety of offerings includes gloves, glasses, garments, and FR clothing made from the highest quality materials available, ensuring maximum safety, comfort, and style.

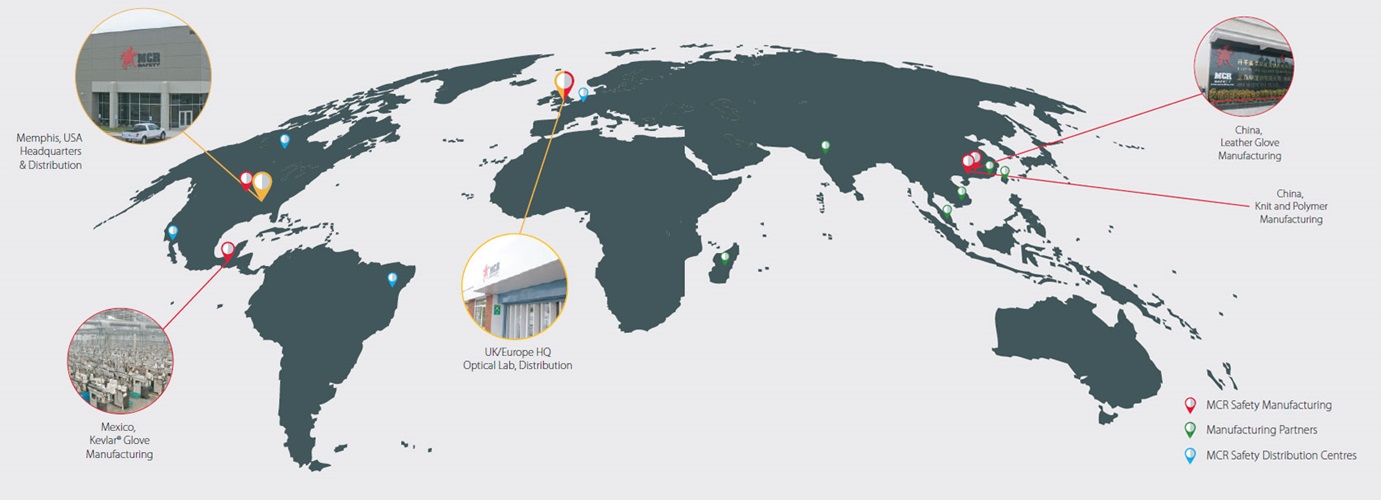

MCR Safety distinguishes itself as a global manufacturer, with operations spanning six continents, highlighted in the image below. Our knowledge as a global manufacturer helps us evaluate multiple buying factors and sources of supply, ensuring reliable, quality, and competitively priced safety products.

MCR Safety's Global Footprint

We’ve come a long way since we started doing business out of a Memphis, TN, garage back in 1974. Today, we employ over 1,600 people internationally, with approximately 300 people working at our corporate headquarters and distribution center in the Memphis area.

We’re one of the largest privately held PPE companies operating in the U.S. For both our distributors and end-users, this goes a long way. With many private glove companies being swallowed up as a product category by larger corporate entities, MCR Safety remains focused on customers and serving our customers with a more personal touch.

U.S. Operations

MCR Safety has become the benchmark for PPE distribution and logistics replicated by others in the PPE industry. Our international headquarters and our 500,000 square foot distribution center are strategically located and support U.S. customers from one of North America’s best central locations, Memphis.

In addition to our Memphis-based facilities, we distribute products to the west coast from our Reno, Nevada, distribution facility. We also have multiple distribution centers strategically located outside the U.S., supporting our international customers.

From our international distribution headquarters, we facilitate a multitude of customer services. Here are just some of the many manufacturing and production operations we conduct:

MCR Safety U.S. Headquarters

- Imprint garments, gloves, and eyewear with custom logos

- Supply the majority of all U.S. PPE distributors

- Manfacture face shields

- Vend pack gloves

- Repackage products for some of America’s largest industrial distributors

- Conduct quarterly focus groups with local end-users

- Provide distributor training events twice a year

In addition to our distribution center, our customer service center is also located in the Memphis area. When you call MCR Safety for customer assistance, you can count on the highest quality level of support, product guidance, and overall assistance from our friendly and knowledgeable customer service representatives.

Product Cross-Reference

Many of MCR Safety’s current product offerings will be moving production to our new factory, taking advantage of the improved facility and the innovations it offers. To simplify which products will take advantage of this move, we’re branding all gloves manufactured in the new facility with the NXG brand. This ultimately means that the current products users purchase from us will be of higher quality, while also protecting our planet by using fewer resources. Here are all the current branded products moving to the NXG brand:

| Material Part No. | Current Branding |

|---|---|

| 9665 | MCR Safety 13 Gauge White Nylon Shell, White PU Coated Palm, Polybag/Pair |

| 9666 | MCR Safety, 13 Gauge Gray Nylon Shell, Gray PU Coated Palm, Polybag/Pair |

| 9669 | MCR Safety, 13 Gauge Black Nylon Shell, Black PU Coated Palm, Polybag/Pair |

| 9674 | UltraTech® Foam, 15 Gauge Nylon Shell, Nitrile Coated Palm |

| 9694 | UltraTech® Air Infused, 15 Gauge Nylon Shell, Air Infused Nitrile Coated Palm |

| 9696 | UltraTech® PU, 13 Gauge Gray Nylon, Gray PU |

| 9699 | MCR Safety, 13 Gauge Black Nylon Shell, Black PU Coated Palm, Polybag/Pair |

| 96655 | MCR Safety, 13 Gauge White 100% Polyester Shell, White PU Coated Palm/Fingertips |

| 96695 | MCR Safety, 15 Gauge Black Nylon Shell, Latex Free, Gray PU Palm/Fingers |

| 96699 | MCR Safety, 13 Gauge, Black Poly Shell, Black PU Palm/Fingers, Polybag/Pair |

| 96715 | MCR Safety, 15 Gauge Salt & Pepper Nylon Shell, Latex Free, Black Foam Nitrile Palm and Fingers |

| 9673 | MCR Safety, 13 Gauge Gray Nylon, Black Foam Nitrile Dipped Palm/Fingers |

| 967315 | MCR Safety, 15 Gauge Gray Nylon Shell, Latex Free, Black Foam Nitrile Palm/Fingers |

| 96731 | MCR Safety Flex, 13 Gauge Gray Shell, Blue Foam Latex Coated Palm/Fingers |

| 9673GW | MCR Safety, 13 Gauge White Nylon Shell, Gray Foam Nitrile Dipped Palm/fingers |

| 9673SF | MCR Safety, 13 Gauge Blue Nylon, Black Foam Nitrile w/Sandy Finish Palm/fingers |

| 96790HVI | Watch Your Hands, 15 Gauge, Gray Nylon Shell, Hi-Vis Orange Nitrile Foam Dipped Palm and Fingertips |

| 9680 | Flex-Tuff®, 10 Gauge Cot/Poly White Shell, Blue Latex Dip Palm/Fingers |

| 9683 | UltraTech®, 15 Gauge White Nylon Shell, Nitrile Coated Palm |

| 9688V | Flex-Tuff® 2, 10 Gauge, Cot/Poly Gray Shell, Gray Latex Dip Palm/fingers |

| 9690 | FlexTherm, 10 Gauge Heavy Weight Gray Acrylic/Cot/Poly Shell, Gray Latex Dip |

| 9690Y | FlexTherm Hi-Vis, 7 Gauge Hi-Vis Yellow 100% Acrylic Shell, Blue Latex |

| FG305 | FlexTuff®, 10 Gauge Cot/Poly Gray Shell, Black Latex Dip Palm/Fingers, Adjustable Wrist |

| FT300 | FlexTuff®, 10 Gauge Cot/Poly Gray Shell w/Blue Latex Dipped Palm and Fingertips |

| FT350 | FlexTuff® Nitrile, 10 Ga Cot/Poly Gray Shell w/Green Nitrile Dip Palm/Fingers |

| 96781 | FlexTuff® KEVLAR, 10 Gauge KEVLAR® Shell, Blue Latex Dip Palm/Fingers |

| MG9694 | MCR Safety, 15 Gauge Black Nylon/Spandex Shell, Back Bi-Polymer Coating w/ Nitrile Dots |

Rest assured, when gloves show up with a new logo,

you can trust they have been upgraded with

NXG technology!

Are you ready for the Next Generation of Gloves?