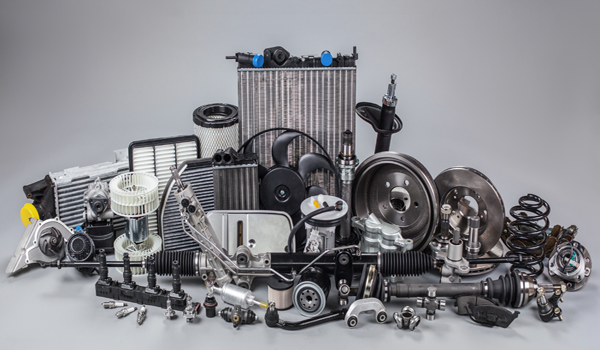

"A single car has about 30,000 parts, counting every part down to the smallest screws."

In 2017, a total of 272.48 million vehicles were registered in the U.S. Each of these vehicles requires a vast number of parts to function and operate. With over 30,000 parts found in a single car, motor vehicle manufacturers rely on key suppliers to assist in bringing these parts to market and to manufacturing assembly lines.

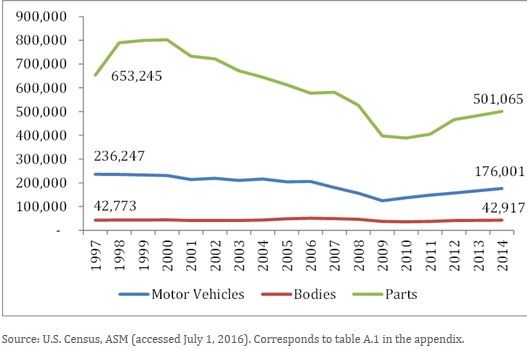

The automotive parts manufacturing industry includes those companies primarily engaged in manufacturing motor vehicle parts. Parts manufacturing is the largest sector of the entire automotive industry.

Demand for auto parts is driven by these three core areas:

Original equipment manufacturers (OEM) supply parts for the production of new vehicles. Parts are continually arriving to the motor vehicle assembly line for new car production. The right parts have to be in the right place at the right time for the assembly line to continue operating efficiently.

Replacement parts are made by the same manufacturer as the new car parts. As the overall quality and reliability of automobiles have increased, the demand for parts only grows larger. Most car manufacturers will keep stamped out body parts for up to 10 years after a vehicle has been produced.

Any part of the vehicle not sourced from the original car manufacturer are aftermarket parts. Aftermarket consumers rely heavily on parts suppliers, with over 70,000 meeting up at the SEMA show in Las Vegas.

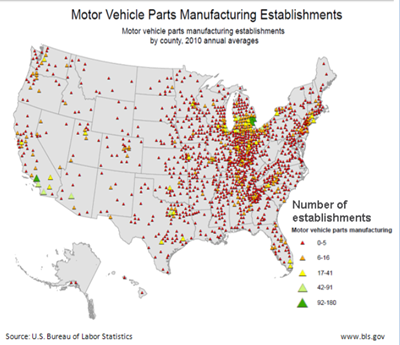

There are over 5,000 companies operating within this industry, with 7 out of 10 manufacturing motor vehicle parts. See the image below from the U.S. Bureau of Labor Statistics (BLS), highlighting where the majority of these parts manufacturers operate.

At any given time, an assembly line can have up to 6,000 parts traveling on it. When you think about it, parts that help make subparts, which ultimately produces the part we all need in our lives: a working vehicle. Without parts, there is no vehicle. Let us take a look at each sub-industry within parts manufacturing.

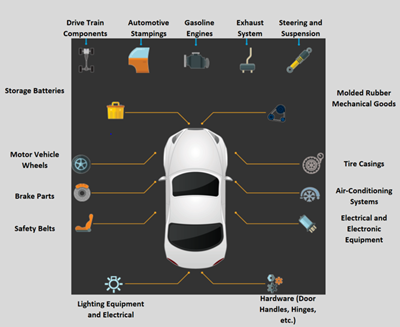

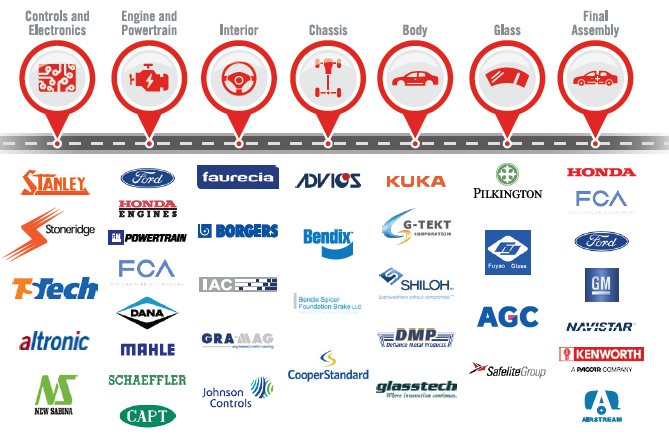

As mentioned above, the manufacturing of the automotive parts that go into vehicles is vast, ranging from gasoline engines to seats, brakes, and electrical systems. Essentially, an automobile is a complex web of systems, parts, subparts, and components assembled into a final product.

The U.S. Census Bureau has created an excellent interactive tool for visualizing all the parts that make up a vehicle. See the image below or click here for the tool.

Major product categories for this industry consist of a number of sub-industries. We highlight each one’s NAICS number, percentage of the overall industry, and the key products made within each sub-industry.

15% of the parts industry involves companies that manufacture gasoline engines and engine parts for motor vehicles. Engines are such an important component of both motor vehicles and industrial equipment, we highlight this one on its own industry page. Examples of Metal Stamped parts include:

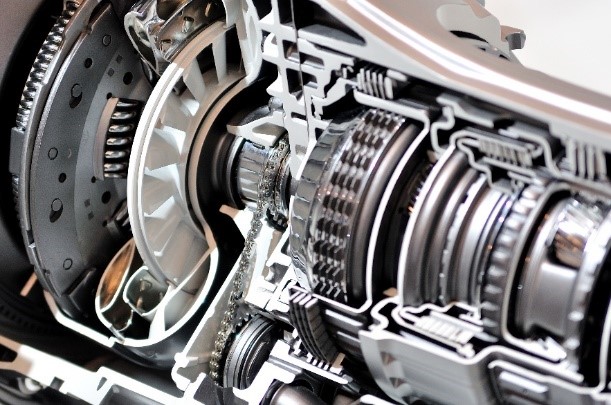

15% of the parts industry are the companies that manufacture motor vehicle transmission and powertrain parts. Examples of Transmission and Powertrain parts include:

15% of the parts industry involves companies that manufacture gasoline engines and engine parts for motor vehicles. Engines are such an important component of both motor vehicles and industrial equipment, we highlight this one on its own industry page. Examples of Engine parts include:

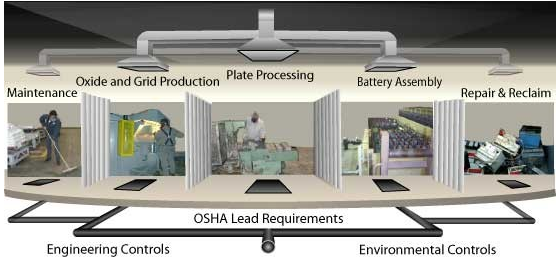

10% of the parts industry are those companies that manufacture electronic equipment for motor vehicles. Electric cars have given rise to new car parts, ranging from lithium batteries to electric motors. Examples of Electrical parts include:

If you work in this industry, be sure to check out OSHA’s eTools on BatteryManufacturing, which covers many of the specific hazards this industry faces.

OSHA eTools for Battery Manufacturing

10% of the parts industry are companies that manufacture motor vehicle fabric and trimmings. Examples of Seating and Trim include:

5% of the parts industry are companies that manufacture motor vehicle brake systems.

5% of the industry are those companies that manufacture motor vehicle steering devices and suspension components.

Other notable parts segments of this industry include exhaust systems, fuel tanks, HVAC systems and air bags. NAICS 33639 captures all companies within this industry not identified in the above NAICS subindustries.

The automotive parts industry is a key contributor to the U.S. economy. Virtually all automotive manufacturers produce their own parts. However, over the years, manufacturers have been turning to first-tier suppliers for the production of just-in-time components. For this reason, many parts suppliers are now as global as the vehicle manufacturers themselves.

IBISWorld reports that total revenue for the parts industry is anticipated to reach reach $73 billion in 2019. It has nearly doubled since 2009 in terms of exports. Since 2003, the overall revenue number has grown, up an almost unbelievable 506% from 2003 to 2013! See the image below.

Most automotive exports are sent to Canada, Mexico, and the European Union.

In addition, the global automotive parts industry is expected to grow around 3.6% and ultimately reach a market valuation of roughly $466 billion by the end of 2025.

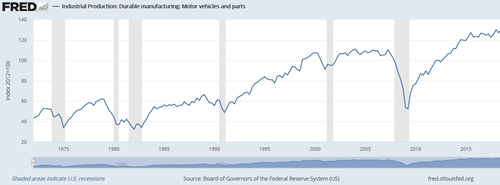

As we mentioned on the Vehicle Manufacturing page, worldwide motor vehicle production has been increasing for decades. Well, you need parts in vehicles, which helps explain why the worldwide demand for parts is increasing. Another positive is that parts production is increasing overall production in the U.S., see below.

Click for larger view

The U.S may not be producing as many passenger vehicles, however, jobs are being created from the manufacturing of automotive parts.

Virtually all automotive manufacturers produce their own parts. However, over the years, manufacturers have been turning to first-tier suppliers for the production of just-in-time components. For this reason, many parts suppliers are now as global as the vehicle manufacturers themselves.

As you know by now, companies in this industry manufacture automobile parts. They operate as either small parts plants, with a relatively small number of workers, to enormous assembly plants that employ thousands. Approximately 49% of motor vehicle parts manufacturing jobs are in establishments employing 500 or more workers.

It's a long supply chain of parts.

Automotive News highlights the top 100 global OEM parts suppliers. Here is a look at some of these employers:

| Company | Employees |

|---|---|

| Lear Corporation | 169,000 |

| Autoliv Inc. | 66,000 |

| TRW Automotive Inc. | 66,000 |

| Tenneco Inc. | 55,000 |

| Magneti Marelli Holding USA LLC | 44,000 |

| Dana Incorporated | 30,100 |

| Cooper-Standard Holding Inc. | 25,000 |

| BorgWarner | 27,000 |

| Visteon | 10,000 |

| American Axle & Manufacturing | 6,160 |

The automotive parts manufacturing industry remains a steady employer for many American workers. The Motor &Equipment Manufacturers Association (MEMA) highlighted back in 2017 that automotive parts manufacturing jobs in the U.S. have risen 19% since 2012. That ultimately means a steady paycheck for many and an increased need to keep these workers safe, which we discuss more below.

Taking a look at the official BLS website, there are roughly 588,000 people employed in the automotive parts manufacturing industry. However, combined with indirect employment, the number jumps to over 4 million. When you take a look at the next image, you can see how parts manufacturing has been on an upward slope the past decade, with growth coming in as MEMA highlighted.

Some might argue that the extreme growth occurring is only a rebound from the drastic decline in employment during the 2008 financial crisis. While there may be some truth to that, the fact remains: the U.S. employs a lot of workers in this industry. Here is a look at the occupations found in this industry.

There is a wide range of automotive careers found in parts manufacturing. Each one of these workers will require PPE designed for their specific everyday work applications. The top three occupations found in this industry are the following:

Here is a look at the positions employing the most workers.

Assemble finished products and parts. There are around 165,650 of these workers in the motor vehicle parts manufacturing. You will find this worker assembling bolts, using many different types of tools, and moving heavy parts. They construct finished products and the parts that go into them. These workers use many tools, machines, and most importantly need their hands protected. Common job titles for this occupation are Assembler and Fabricator.

Lubricates machines, changes parts, and performs machinery maintenance. The Motor Vehicle Parts Manufacturing industry employs a little over 33,000 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil, and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Around 28,000 of these workers help move material in Motor Vehicles Parts Manufacturing. That is a large number of hands needing to be protected. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

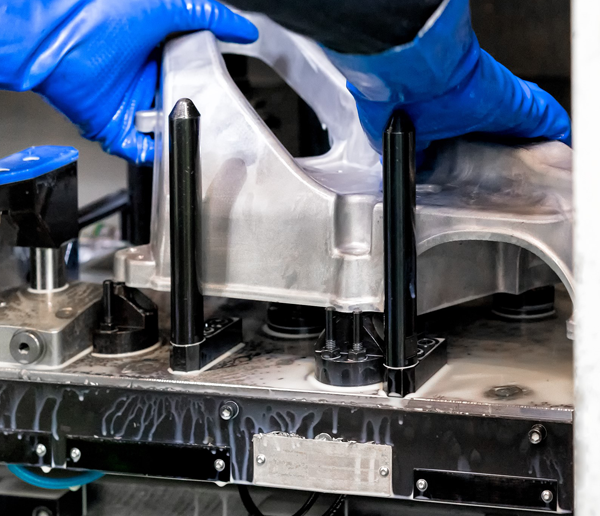

Operate cutting and forming machines. There are roughly 26,000 of these workers in motor vehicle parts manufacturing. The majority of these workers are employed in aluminum production. You will find these workers changing cutting tools, aligning parts, and inspecting metalwork pieces. Common job titles for this position are CNC Machine Setter, CNC Machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

Use machines and cutting tools. This occupation is highly skilled at operating machinery. There are around 21,000 of this occupation working in the motor vehicle parts manufacturing industry. You will find this worker operating machine tools to produce precision parts. Job titles for this position are Gear Machinist, Machine Operator, and Maintenance Machinist.

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. There around 2,600 workers found in Motor Vehicle Parts Manufacturing. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 21,000 of these workers found in motor vehicle parts manufacturing. You will find these workers aligning metal parts and grinding out burrs or sharp edges. This makes cut-resistant gloves a high priority for this worker. Common job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, and Press Punch Operator.

Workers that move materials, objects and stock. There around roughly 19,000 of these workers in the Automotive Parts Manufacturing industry. Machine feeders also fall into this worker group. Common Job titles for this position are Line Tender, Laborer, and Materials Handler. Due to the use of one’s hands, wearing gloves is a must.

Lay out metal stock, operate machine tools, and assemble parts to make and repair dies. There are roughly 13,000 of these workers in the motor vehicle parts manufacturing industry. You will find these workers cutting and shaping metal, along with assembling machine fixtures. Common job titles for this position are Die Maker, Die Machinist, and Tool Repairer.

Operate casting or coremaking machines to mold or cast metal. Workers are known as pourers or casters. Around 12,000 work in the motor vehicle parts manufacturing industry. Common job titles for this position are Core Machine Operator, Mold Technician, and Die Cast Technician.

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 11,900 of these workers are employed in the Motor Vehicle Parts Manufacturing industry. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

Repair, install, and adjust industrial machinery. There are around 11,000 of this occupation working in motor vehicle parts manufacturing. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial Mechanic, and Master Mechanic.

Keep machines, mechanical equipment, or the structure of an establishment in repair. There are around 10,000 of this occupation that works in the Motor Vehicle Parts Manufacturing industry. You will find these workers pipe fitting, repairing equipment, and repairing buildings. Job titles for this position are Maintenance Worker, Maintenance Mechanic, and Facilities Manager.

Duties include supplying or holding materials, along with cleaning work areas and equipment. Around 8,000 of these workers are in the Motor Vehicles Parts Manufacturing industry. You will find these workers attaching cables, changing machine gears and handling a lot of material. All of these activities make gloves extremely important. Common Job titles for this position are Laborer, Press Helper, and Material Handler.

Perform tasks involving physical labor at motor vehicle manufacturing plants. There are roughly around 6,000 of these workers found in motor vehicles parts manufacturing. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common job titles for this occupation are Helper, Laborer, Post Framer, and Construction Worker.

Perform tasks involving physical labor. There around 6,200 of these workers in Motor Vehicle Parts Manufacturing. They operate hand and power tools of all types. You will find these workers preparing sites, digging trenches, erect scaffolding, applying paint to surfaces, sealants and assembling structures. Common job titles for this occupation are Helper, Laborer, Skill Laborer

Operate machines to taper, shape, and form metal. Around 5,100 of these workers are found in motor vehicle parts manufacturing. You will find these workers removing dies, forging hammers, and moving metalwork pieces. Common job titles for this position are Forger, Blacksmith, Hammer Operator, and Forge Press Operator.

You will find these workers applying paint coatings, cleaning production equipment, and positioning work pieces. There are roughly 3,100 of these workers in the Motor Vehicle Parts manufacturing industry. They paint and coat surfaces. Workers are exposed to many contaminants. Common job titles for this occupation is Painter and Spray Painter.

Operate grinding tools that remove excess metal material or burrs. There are around 3,000 of these workers in motor vehicle parts manufacturing. You will find these workers sharpening edges and corners, along with polishing metal. Common job titles for this position are Deburrer, Finisher, Grinder, and Grinding Operator.

Operate machines to coat or paint a wide variety of products. Examples include cloth, glassware, cloth, copper, ceramics, metal, plastic, paper, wood, silver, and rubber. There around 2,500 of these workers in motor vehicle parts manufacturing. You will find these workers mixing ingredients and cleaning production equipment. Noise levels are a concern for these workers. Common job titles for this occupation are Coater Operator, Paint Technician, Silk Screen Operator, and Spray Painter.

Operate plating or coating machines to coat metal and plastic products with other metal, such as chromium, zinc, copper, cadmium, and nickel, to protect surfaces. There are around 2,100 of these workers in the motor vehicle parts manufacturing industry. You will find these workers trimming excess material from workpieces, heating material, loading items into ovens, and cutting material. These workers must wear PPE due to the many contaminants encountered. Common job titles for this occupation are Chrome Plater, Galvanizer, and Plater.

Install, dismantle, or move machinery and heavy equipment. There are around 1,900 of these workers in Motor Vehicle Parts Manufacturing. You will find this worker adjusting bolts, positioning parts, using hand tools, and drilling holes. Common job titles for this occupation are Maintenance Mechanic and Precision Millwright.

Operate machines that extrude metal materials into tubes, wires, and bars. Around 2,000 work in motor vehicle parts manufacturing. You will find these workers loading materials into machines. Common job titles for this position are Extruder Operator, Wire Mill Remover, Extrusion Press Operator, and Metal Inspector.

Operate machines designed to cut, shape and form metal. There are roughly 1,600 employees found for this occupation. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Common job titles for this position are Sheet Metal Worker and Welder.

Operate machines to crush, grind, and polish materials. There are roughly 1,400 of these workers found in the motor vehicle parts manufacturing industry. You will find these workers mixing chemicals, collecting materials, and using picks. Common job titles for this position are Batch Mixer, Fabricator, and Miller.

Operate machines that plate, roll, and flatten steel. Around 1,400 of these workers are found in the motor vehicle parts manufacturing industry. You will find these workers around shears, grinders, and adjusting machines. Common job titles for this position are Rolling Mill Operator, Mill Operator, and Roll Form Operator.

Gather and empty trash, sweep, mop, or vacuum building floors, clean and stock restrooms. There are roughly 1,400 of these workers in motor vehicle parts manufacturing. You will find this worker keeping buildings clean, orderly, and in good condition. These workers spend a lot of time standing and are exposed to contaminants. Common job titles for this occupation are building Custodian, Cleaner, and Janitor.

Assemble, install, and repair pipes, fittings, heating fixtures, and drainage systems. There are around 1,300 of these workers in the motor vehicle parts manufacturing industry. You will find these workers installing piping, welding metal, and cutting openings in structures. They are exposed to hot and cold temperatures and exposed to cuts and minor burns. Common job titles are Commercial Plumber, Drain Cleaner, and Master Plumber.

Motor vehicle manufacturing and parts manufacturing have two things in common: assemblers and maintenance workers are needed for both. Aside from that, they are two completely different worlds. Within parts manufacturing, you will find more CNC workers, machinists, and welders.

Here are what workers in this industry do on a daily basis:

Many of the activities found in the automotive industry involve metal fabrication. Be sure to check out our Metal fabrication industry page for more information and resources.

Creating automotive parts involves many workplace hazards, which means it is imperative that workers think before they act. Workers must pay close attention to what they’re doing, no matter what task is being performed, or someone is going to get hurt.

In 1985, one Chicago parts manufacturing company had 41.8 injury cases per 100 full-time employees, roughly four times that of the industry. Well, that number has come down significantly over the years as better safety processes have been implemented, plant inspections have increased, and PPE technology has been worn.

The parts manufacturing industry, NAICS 3363, experiences around 22% more injuries than the average for all industries. However, when you peel the onion back on this industry, tne sub-industry today that should still take safety and PPE rather seriously is the motor vehicle stamping industry. 6.3 injuries occur for every 100 employees, which is 36% higher than the average for all parts manufacturing sub-industries. It is 50% higher than the 3.2 average for all U.S. industries. High ANSI cut-resistant gloves should be worn by the majority of workers, and definitely by those handling sharp metal materials.

| Parts Sub-Industry | NAICS | # of Injuries for Every 100 Employees |

|---|---|---|

| Motor vehicle metal stamping | 33637 | 6.3 |

| Motor vehicle brake system manufacturing | 33634 | 4.3 |

| Motor vehicle seating and interior trim manufacturing | 33636 | 4.2 |

| Other motor vehicle parts manufacturing | 33639 | 4.2 |

| Motor vehicle gasoline engine and engine parts manufacturing | 33631 | 3.6 |

| Motor vehicle steering and suspension components (except spring) manufacturing | 33633 | 3.6 |

| Motor vehicle electrical and electronic equipment manufacturing | 33632 | 3.3 |

| Motor vehicle transmission and powertrain parts manufacturing | 33635 | 3.0 |

Companies that make safety a high priority and embrace safe working conditions are much likelier to avoid workplace injuries. MCR Safety places a high priority on safety – it’s what we do. We Protect People!

As the automobile industry adapts to future technologies and new parts, MCR Safety will be there evolving along the way, adapting PPE to fit the employees’ needs and keeping automotive workers safe at work.

Find the right MCR Safety product that protects you against these common hazards.

Hydraulic lifts have eliminated a lot of heavy lifting, however, workers still have to lift some heavy objects.

Auto parts manufacturing employs the most auto assemblers in the entire industry. Feeling fine parts requires cut protection and high dexterity. With recently advanced fibers introduced, we've got you've covered!

Laying out metal stock and repairing dies requires reliable cut protection.

When you have to grip parts all day long, gloves with excellent coatings are preferred.

Workers in the parts industry coat and plate metal. They also work around hot machinery and hot parts. Heat protection is what this worker requires.

Metal shavings are found all over work areas in parts manufacturing facilities. Protective eyewear is essential PPE for workers.

Thinner gauged material used for parts doesn't require heavy forming equipment like heavy metal stamping. As always, the higher the ANSI cut score, the better the protection.

In the surface treatment of metal parts, hydrofluoric acid is used and can be hazardous if a worker comes in contact with it. Check out our Chemical Permeation Guide for specific chemical breakthrough times.

Learn More About Liquids and Chemicals Protection

Handling small components to make parts is an everyday task for the automotive parts worker. Removing parts from hooks and stacking parts require excellent protection.

Many workers come into contact with oil and grease. We've got Grippaz™ disposable liquid protection that offers excellent grip, too.

Learn More About Metalworking Fluids Protection

Parts sometime need to be painted, which means workers need protection from the paint being sprayed.

Arms and hands are easily lacerated by tossing metal parts or when feeding metal pieces to robotics. Our Cut Protection page will easily allow you to choose gloves by ANSI cut score.

Loading finished parts onto hand-trucks requires only the best protection.

Welders need shaded eyewear when cutting and grinding or when exposed to searing rays. Be sure to check out our Welding Protection page for more information.

Learn More About UV Radiation Protection

Welding operations generate hazardous working conditions that require protective gloves, glasses, and garments. Be sure to check out our Welding Protection page for more information.

Learn More About Welding Protection

Stacking and handling finished welded parts occurs every day in this industry. A cut-liner under the leather palm is the way to protect hands. Be sure to check out our Welding Protection page for more information.

Learn More About Welding and Cut Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.