“A bad attitude is like a flat tire; you can't go anywhere until you change it.”

Yes, it is true; a bad attitude and a flat tire have much in common, as both prevent one from moving forward in life. With that said, there was a time thousands of years ago when the concept of a tire did not exist, much less a rolling wheeled object.

To fully appreciate the tire, one must first appreciate the wheel. The creation of the wheel is one of humanity’s most ancient and greatest inventions; so valuable that it continues to transform our modern world. Some 5,000 years after its discovery, the wheel is as influential today as it was with that first wheelbarrow. Without the wheel, we wouldn’t have automobile tires to help us get us from point A to point B.

The automobile tire is a ring-shaped rubber cushion that fits and surrounds a wheel’s rim and is filled with compressed air. The next couple of images help visualize how the wheel and tire are linked.

Ancient Wheel

Modern Wheel and Tire

The U.S. tire manufacturing industry is made up of companies that manufacture tires and inner tubes from natural and synthetic rubber. Tire are manufactured for a wide range of moving vehicles: automobiles, trucks, business, aircraft, tractors, shopping carts, bicycles, and motorcycles.

Below, we highlight the history of tires, the manufacturing process, types of tires, and their economic impact. Most importantly, we highlight the hazards workers face when manufacturing tires and the PPE they should consider wearing while on the job.

First pneumatic bicycle tire found at the National Museum of Scotland

The wheel, on its own, when rolled across surfaces, begins to wear and tear. As the 19th century ended and bicycles were becoming popular, an outside layer added to the wheel was needed to absorb damage and minimize wear. This is where the tire debuted on the world scene, providing strong absorption and a smooth ride.

Early tires took on the appearance of leather bands wrapped around a wooden wheel. The solid rubber tires that followed after these initial designs owe their existence to Charles Goodyear, who discovered vulcanization in 1839, which is the process of curing rubber with sulfur and lead. It turns sticky rubber into a stable material, perfect for manufacturing tires.

By 1888, the tire industry was set, when John Boyd Dunlop created the first successful pneumatic tire, an air-filled tire rather than one made of solid rubber. It reduced vibration and improved traction with the road, providing users with a smoother overall ride.

Radial tire, which dominates today’s tire industry

Today, two different types of pneumatic tires are constructed: bias and radial construction. The tire’s belt is what separates the two, with radial tires being strengthened by steel fabric.

Over 200 raw materials makeup a tire’s composition, ranging from the following: wire, rubber, chemicals, carbon black, oil, nylon, polyester, and steel. Ultimately, the material that goes into a tire impacts worker safety. For example, different chemicals require different glove polymers, and sharp metal may require higher ANSI-rated cut gloves.

Here are the core materials that make up a rubber tire:

Even though a tire is made up of these three core materials, not all tires manufactured are the same. Different tire treads are crucial to performance in different types of driving conditions.

Tires are broken up into a couple of major product categories, and then a variety of tires are made within each category. Passenger car tires make up the bulk of tire production, with 45% of all tires made, followed by truck and bus tires with 30%. Industrial tires are the smallest category of tires produced. Below are the types of tires manufactured for different vehicles and environments:

Passenger tires are engineered for a variety of driving experiences. In 2018, the U.S. Tire Manufacturers Association (USTMA) reported that 46.2 million tires were shipped for OEM and 214.9 million were shipped as replacement tires. Here are some types of passenger tires:

Truck and SUV tires need to meet a wide selection of driving needs and end uses. In 2018, the U.S. Tire Manufacturers Association (USTMA) reported that 11.5 million tires were shipped for OEM and 52.6 million were shipped as replacement tires. Here are some tires specific to SUVs and trucks:

Tires fit a wide variety of vehicles, from ATVs to trailers. Here are some specialty tire types:

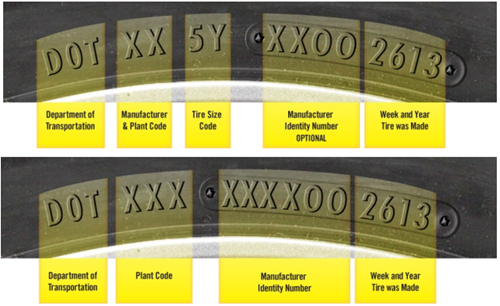

There’s a ton of important information located right on your tires. That’s right, those side numbers do mean something. Just click the images below to learn more.

A tire’s date means something.

The U.S. Tire Manufacturers Association (USTMA) reported that a total of 325.2 million tires were shipped in 2018. The overall industry is forecasted for $19 billion in revenue in 2019.

Demand for tires is ultimately impacted by new vehicle sales and the need for replacement tires. As we highlighted on our Motor Vehicle Manufacturing page, worldwide production for automobiles is at an all-time high. The increased production has, in turn, increased demand for tires.

The largest tire manufacturing companies operating in the U.S. are Bridgestone, Goodyear, Michelin, and Cooper Tires. These top four tire manufacturing companies generate more than 70% of tire manufacturing revenue.

Out of 62 plants operating in the U.S., yearly tire capacity for all North American tire manufacturing plants was 334.8 million tires in 2018. Here is a list of some of the largest operating plants within each state.

| State | City | Capacity (in thousands per day) | Company |

|---|---|---|---|

| AL | Gadsden | 26 | Goodyear |

| AL | Dothan | 5 | Michelin Tire |

| AR | Texarkana | 32 | Continental |

| GA | Macon | 11 | Kumho Tire |

| IA | Des Moines | 4.57 | Bridgestone |

| IL | Mount Vernon | 41 | American Industrial Partners |

| IL | Mount Vernon | 3.9 | American Industrial Partners |

| IN | Fort Wayne | 30.5 | Michelin Tire |

| KS | Topeka | 6.1 | Goodyear |

| MS | Tupelo | 42 | Continental Tire |

| NC | Fayetteville | 41.5 | Goodyear |

| NC | Wilson City | 35 | Bridgestone |

| OH | Findlay | 23 | Continental Tire |

| OK | Lawton | 64.5 | Goodyear |

| OK | Ardmore | 44 | Michelin |

| SC | Aiken | 35.7 | Bridgestone |

| SC | Greenville | 28 | Michelin Tire |

| SC | Lexington | 24 | Michelin Tire |

| SC | Sumter | 12.6 | American Industrial Partners |

| SC | Greenville | 7 | Michelin Tire |

| TN | Clinton | 41 | American Industrial Partners |

| TN | Jackson | 15 | American Industrial Partners |

| TN | Clarksville | 10 | Hancook Tire |

| TN | Warren County | 9 | Bridgestone |

| TN | La Vergne | 6.2 | Bridgestone |

| VA | Danville | 13 | Goodyear |

Yearly tire capacity for all of North America totaled 334.8 million tires. The new Giti Tire plant located in South Carolina is helping prop up U.S. total production numbers is projected to produce 5 million tires annually.

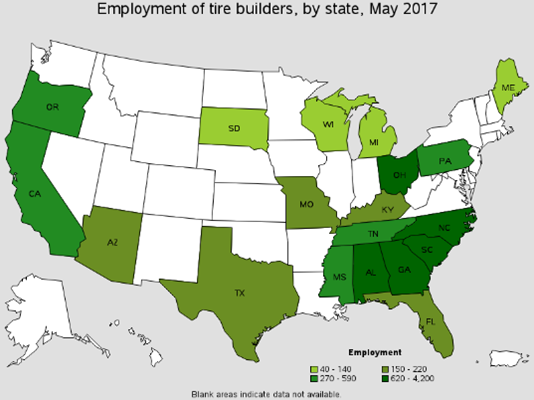

According to the Bureau of Labor Statistics (BLS), the Rubber Manufacturing Industry employs a little over 134,000 individuals. Of that, the tire industry itself employs roughly 70,000 workers. Out of this number, around 22,000 are referred to as tire builders. Here is a snapshot of the states employing the most tire builders:

| State | Employment |

|---|---|

| South Carolina | 4,200 |

| Alabama | 2,040 |

| Georgia | 1,830 |

| North Carolina | 1,710 |

| Ohio | 620 |

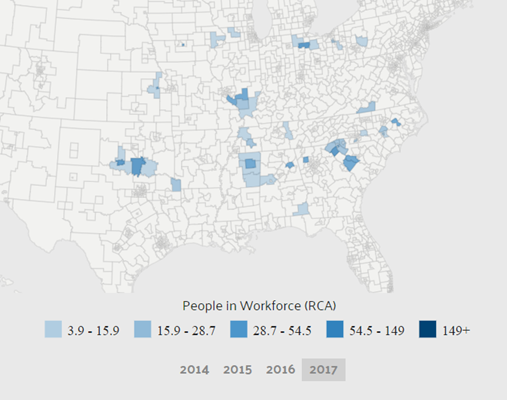

Data USA maps out the counties in each state with the highest rates of tire manufacturing employment.

County Employment According to Data USA

Manufacturing a tire involves multiple steps. Here is a breakdown of the overall process:

Raw materials are measured before being moved into the mixers.

Samples are tested.

The Banbury mixer (compounder) prepares the ingredients and the raw materials are mixed to specific tire recipes. These recipes call for rubber, carbon filler, chemicals, and oil.

Rubber trees producing one of the core material found in tires.

It begins on a revolving drum. Several operations occur during this stage to produce a tire’s key components. Here are primary activities found at this stage:

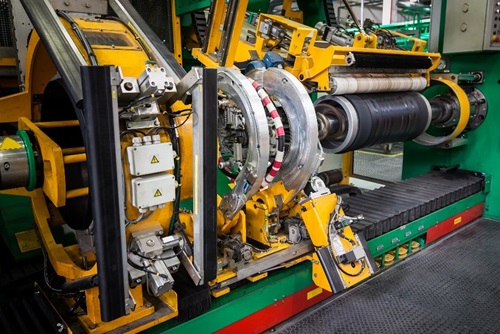

Components from the above steps are sent to the green tire building machine and assembled. Previously calendared fabric (called a ply) wraps around the drum and a bead bundle is placed on the edge.

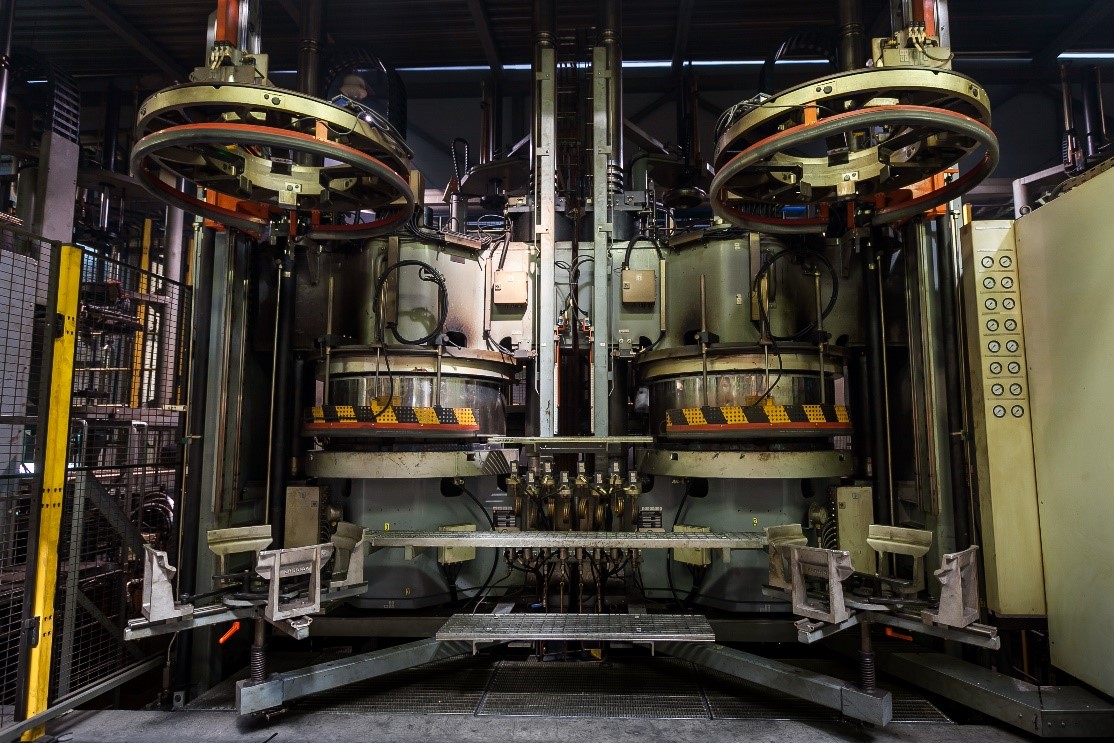

Tire Building Machine

The green tire is put over the bladder, using steam to heat up the curing press platen. This provides for a resilient and durable finished tire.

Image from the Library of Congress, showing a mid-20th century worker placing a tire in the mold before vulcanization.

Tires are inspected for specific level requirements.

Multistrada, a producer of tires, has created the visual aid below to illustrate the tire manufacturing process.

Here is a look at the occupations found in this industry.

The top three occupations found in this industry are the following:

To manufacture tires, you need workers. Based on the Bureau of Labor (BLS) statistics for Rubber Manufacturing, which includes Tire Manufacturing, here is a snapshot of the main occupations:

A vehicle requires tires to be occasionally changed once the tread wears down. There are around 1,220 members of this occupation in the rubber and tire manufacturing industry. You will find these workers remounting wheels, removing puncturing objects, and assisting mechanics.

An automobile has at least four tires, which means a lot of rubber tires are needed for a vehicle to run. This worker operates machines to build tires. There are around 22,000 members of this occupation in the rubber and tire manufacturing industry. You will find these workers trimming excess rubber, cutting plies, and painting solvents.

Machines are operated to crush, grind, and polish materials. There are around 3,300 members of this occupation in the rubber and tire manufacturing industry. You will find these workers crushing and grinding materials, along with mixing chemicals.

Metalworkers are needed across the entire automotive industry, creating individual parts and repairing metal structures. There are around 11,000 members of this occupation in the rubber and tire manufacturing industry. You will find these workers welding, cutting, shaping, and forming metal pieces. Vehicles have metal everywhere across their bodies, which means a lot of metal must be shaped to the correct size.

A multitude of automotive parts are shaped to different dimensions. There are around 3,100 members of this occupation in the rubber and tire manufacturing industry. You will find these workers inspecting metal workpieces and operating machines such as lathes, cutters, and shears to make metallic and plastic workpieces.

The entire automotive industry has many objects moving at all times. There are around 4,130 members of this occupation in the rubber and tire manufacturing industry. You will find this occupation loading docks, moving parts, moving materials to production areas, and moving finished vehicles to warehouses.

Automotive factories have many machines that need to be maintained and repaired. There are around 9,690 members of this occupation in the rubber and tire manufacturing industry. A maintenance worker must be skilled in electricity, welding, and mechanical systems. You will find these workers repairing equipment and cleaning machines and machine parts. Cleaning solvents, oily parts, and metalworking fluids are a definite concern for these workers.

Industrial Mechanics repair and maintain industrial production and processing machinery. There are around 2,800 members of this occupation in the rubber and tire manufacturing industry. You will find these workers cutting and welding metal to repair broken metal parts.

Automotive parts are needed in all shapes and sizes, including rods and other structural shapes. There are around 15,000 members of this occupation in the rubber and tire manufacturing industry. You will find these workers operating machines to extrude or draw thermoplastic or metal materials into tubes, rods, hoses, wire, and bars.

The rubber used in tire manufacturing needs to be cut to exact lengths. There are around 2,000 members of this occupation in the rubber and tire manufacturing industry. These workers operate machines that cut/slice materials, such as glass and rubber.

The workers in the tire manufacturing occupations listed above engage in a wide range of activities. Here are just a handful of the hundreds of activities performed across this industry.

1910 Akron Tire Workers

Many of the activities found in the automotive industry involve metal fabrication. Be sure to check out our Metal fabrication industry page for more information and resources.

Worker safety is important to the tire manufacturing industry. It is a dangerous industry, with about 22% more injuries per year compared to the average for all industries.

Manufacturing tires is hazardous primarily because it involves humans interacting with numerous dangerous operations, as we highlighted in the Activities section. When working with rubber, many injuries occur due to manual handling, such as loading materials into production equipment. In addition, because chemicals make up the main material in tires, you can bet workers come into contact with hazards substances. Thankfully, MCR Safety makes gloves that protect against harsh chemicals.

The good news is the U.S. Tire Manufacturers Association (USTMA) recognizes those companies advancing occupational health and safety. MCR Safety assists safety managers in advancing safety in their production areas by offering the most advanced PPE found in the marketplace. Below, we highlight the hazards workers face in the industry.

Let us keep you safe when building tires. We Protect People!

Find the right MCR Safety product that protects you against these common hazards.

Manufacturing tires involves a mixture of hundreds of chemicals throughout the manufacturing processes. Possible exposures include N-nitrosamines, polycyclic aromatic hydrocarbons, solvents, and phthalates. MCR Safety offers a wide range of chemical resistant gloves for different chemicals encountered. Be sure to check out our Chemical Permeation Guide for specific chemical breakthrough times.

Exposure to hazardous equipment is a definite concern for workers in this industry. Loading materials into production equipment and mounting workpieces are examples in Tire Manufacturing. Wearing gloves with 360-degree protection makes a lot of sense. Check out our Impact Protection Page for additional information.

Learn More About Crush Protection

There is no need in sacrificing liquid protection for cut protection or vice versa. We’ve made our new Predastretch glove equipped with a cut liner! We keeping adding on features to glove we know workers require.

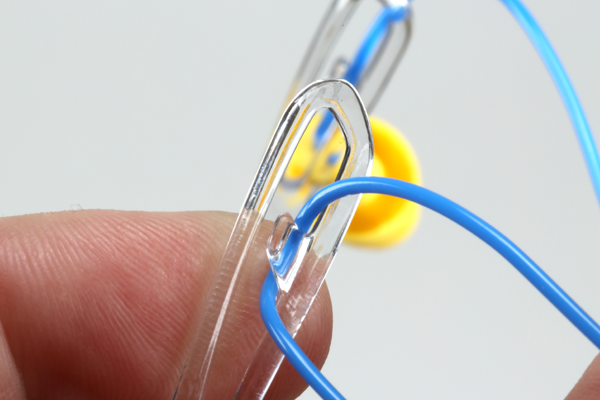

Tire manufacturing workers use their hands to handle, feel and touch many objects. We continue innovating featherweight fibers that provide cut protection and ultimate dexterity for handling the smallest objects workers touch. Be sure to check out our Cut Protection page for additional information.

Learn More About Cut and Sense of Touch Protection

Lacerations are always a concern when you’re manipulating any material. In this industry, using knives to cut camelback and cutting industrial materials for fabrication is when cut protecting gloves need to be worn. Be sure to check out our Cut Protection page for additional information.

Learn More About Cut and Sharp Objects Protection

Grinding and trimming rubber during inspection and finishing may entail exposure to rubber dust. We manufacture a wide range of lined eyewear styles, chemical goggles, and an ANSI D4 dust rated goggle.

Maintaining a solid grip is essential when placing tires into molds, assembling tire components, mounting tires and positioning rollers that turn ply edges. MCR Safety’s coated gloves are dipped with premier coatings to ensure you maintain a solid grip. Be sure to check out our blog "Top Gripping Properties".

Learn More About Grip Protection

Workers handle, weigh and mix many raw materials. For those only requiring minimal liquid and material exposure, consider Grippaz disposal protection for enhanced grip properties.

Learn More About Grip and Liquid Protection

Workers are exposed to heat throughout tire manufacturing, from the mechanics working on hot machines to workers exposed to hot curred rubber. Sometimes you need to match rubber with rubber, like with our 9687 rubber coated highly heat-resistant and cut-resistant glove. We’ve written a Heat Resistant Gloves blog to keep you informed!

Learn More About Heat Protection

Hot objects and chemicals are present in tire manufacturing. If you have to work around both hazards, consider wearing our 6944, which offers ANSI Contact Heat level 5 protection and chemical protection.

Learn More About Heat and Chemicals Protection

A release of pressurized air is always a concern for workers. Keeping those eye protected during the explosive separation of components is a 100% must.

Sounds are a little uncomfortable at times in tire manufacturing operations. Our new CL4 eyewear allows workers to keep their eyewear close by.

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.