"This is the story of a business that happened because two young lumber dealers in Arizona were in a hurry."

In our modern drone world, where flying objects now deliver goods, it is hard to believe how far we have come in a rather short time span. When the 20th century began, horses and mules were still pulling wagons to deliver large hauls.

An Old-School Trailer: The Covered Wagon

In 1914, E.W. Bennett and H.C. Bennet innovated the first mechanical brake to be used on a trailer and it reshaped the way people hauled goods. As the Forum newspaper quote above highlights, these two men transformed an industry built around horse-drawn trucks to a speedier means of transporting goods. The new trailer allowed one person to pick up and transport materials. In addition, much larger objects, that previous trailers could not accommodate, were able to be transported.

Today, we refer to the trailer industry as the motor vehicle body and trailer manufacturing industry. Within the industry, companies manufacture any one of the following:

Before highlighting the safety hazards this industry faces, let's highlight the different sub-industries.

Companies within this trailer manufacturing sub-industry build truck bodies, bus bodies, cabs, and automobile bodies.

Examples of Trailers include:

Trucks and buses are made up of three core parts: the chassis, the body, and the engine.

Companies within this segment of the industry manufacture truck trailers, truck trailer chassis, cargo container chassis, and detachable trailer bodies.

IBISWorld reports that revenues for this industry will hit $11.9 billion in 2019. Two of the largest companies in this industry are the Wabash National Corporation and Utility Trailer Manufacturing.

Users require different hauling requirements, which means there are variations in the final product supplied.

Examples of Trailers include:

IBISWorld reports that revenues from motor home manufacturing reached $51.1 billion in 2018. Since Americans are taking more and more domestic trips, it is projected that this industry will continue to grow. There are currently 54 companies operating in this sub-industry, which manufactures self-propelled recreational vehicles (RVs) that offer living accommodations and an engine built together.

Examples of Trailers include:

There are roughly 132 companies operating in this sub-industry. They manufacture one of the following:

Examples of Trailers include:

Demand for new trailers is tied to different external factors and the success of other industries. Within the truck trailer manufacturing industry, demand is often affected by agriculture, construction, manufacturing, and retail. On the other hand, motor home manufacturing is directly tied to those consumers planning to hit the open road for vacation.

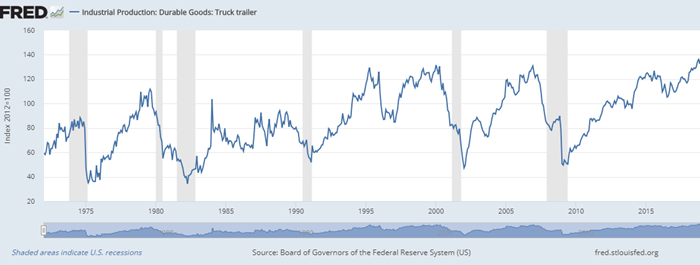

As with other automotive industries, trailer production has been on the rise since the economic downturn of 2008. In the Federal Reserve’s image shown below, you can tell how trailer manufacturing is deeply impacted when downturns occur. Less consumer goods shipping means less demand for trailers.

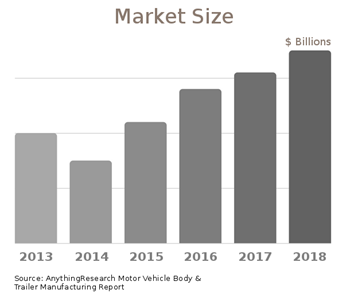

The good news is that market size has been growing during the last decade’s economic expansion.

The Bureau of Labor Statistics (BLS) reports there are around 147,850 employees working in the motor vehicle body and trailer manufacturing industry. As is common across all motor vehicle manufacturing industries, assemblers maintain the dominant employment position, accounting for about 54,500 employees. Here is a breakdown of employment found in the four main sub-industries.

| NAICS | Sub-industry | Employment |

|---|---|---|

| 336211 | Motor vehicle body manufacturing | 46,419 |

| 336212 | Truck trailer manufacturing | 33,924 |

| 336213 | Motor home manufacturing | 10,875 |

| 336214 | Travel trailer and camper manufacturing | 52,431 |

Trailer manufacturing companies design and manufacture vehicles built to endure thousands of miles of hardship and rough travel.

Most specialize in building equipment with a specific purpose, as we highlighted above. The six largest trailer manufacturing companies produce around 80% of the entire number of trailers. In 2015, that total number was 340,000 units.

Major companies include Great Dane Limited, Hyundai Translead, Utility Trailer Manufacturing Company, and Wabash National. The table below shows where some of the largest trailer companies call home.

| Company | City | State |

|---|---|---|

| ATW | Richardson | TX |

| Blue Bird Global Corporation | Fort Valley | GA |

| Great Dane, LLC | Chicago | IL |

| Heil Trailer | Chattanooga | TN |

| Imperial Group Manufacturing | Denton | TX |

| McNeilus | Dodge Center | MN |

| Utility Trailer Manufacturing | City of Industry | CA |

| Volvo Group North America, LLC | Greensboro | NC |

| Wabash National | Lafayette | IN |

Indiana is one of the key states for employment in this industry, thanks in large part to Wabash. California is the 3rd largest state for trailer manufacturing. With that said, there are some states where you don’t find any trailer manufacturing.

Here are the top U.S. states for trailer manufacturing, as reported by the U.S. Census Bureau.

| State | Number of Manufacturers |

|---|---|

| Indiana | 198 |

| Texas | 159 |

| California | 149 |

| Pennsylvania | 99 |

| Ohio | 91 |

| Florida | 73 |

| Missouri | 64 |

| Iowa | 61 |

| North Carolina | 61 |

| Michigan | 58 |

As we’ve pointed out on our other automotive industry pages, the one occupation found across each sub-industry is assembly work. So, as you would guess, assemblers make up the largest occupation in this industry. There are some differences though. There are more painters and welders in this industry as compared to motor vehicle manufacturing. The top three occupations found in this industry are:

Here are all the occupations found in this industry:

Assemble finished products and parts. There are around 54,500 of these workers in Motor Vehicle Body and Trailer Manufacturing. You will find this worker assembling bolts, using many different types of tools, and moving heavy parts. They construct finished products and the parts that go into them. These workers use a lot of tools, machines, and most importantly need their hands protected. Common job titles for this occupation are Assembler and Fabricator.

Operate machines designed to cut, shape and form metal. There are roughly 29,000 employees found for this occupation. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Common job titles for this position are Sheet Metal Worker and Welder.

Use hand welding, flame cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 20,000 of these workers are employed in the Motor Vehicle body and trailer manufacturing. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator.

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. There around 1,500 workers found in the Motor Vehicle Body and Trailer Manufacturing. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Lubricates machines, changes parts, and performs machinery maintenance. The Motor Vehicle Body and Trailer Manufacturing industry employs a little over 7,000 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil, and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

You will find these workers applying paint coatings, cleaning production equipment, and positioning work pieces. They paint and coat surfaces. There are around 5,600 of these workers in the Motor Vehicle and Body Manufacturing industry. Workers are exposed to many contaminants. Common job titles for this occupation is Painter and Spray Painter.

Around 5,600 of these workers help move material and vehicles in the Motor Vehicle Body and Trailer Manufacturing industry. That is a large number of hands needing to be protected. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

Workers that move materials, objects and stock. Around 4,200 of these workers are found in Motor Vehicle Body and Trailer manufacturing. Machine feeders also fall into this worker group. Common Job titles for this position are Line Tender, Laborer, and Materials Handler. Due to the use of one’s hands, wearing gloves is a must.

Polish work pieces, mix ingredients, and operate painting equipment. There are around 4,000 of these workers in the motor vehicle body manufacturing industry. They operate machines used to paint the surfaces of automobiles, buses, trucks, trains, boats, and airplanes. These workers are exposed to many hazardous conditions and contaminants. Common job titles for this occupation are Automotive Painter, Finish Painter, and Paint Technician.

Operate cutting and forming machines. There are roughly 3,100 of these workers in the motor vehicle body and trailer manufacturing industry. The majority of these workers are employed in aluminum production. You will find these workers changing cutting tools, aligning parts, and inspecting metalwork pieces. Common job titles for this position are CNC Machine Setter, CNC Machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

Perform tasks involving physical labor. There are roughly around 3,000 of these workers found in trailer manufacturing. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common job titles for this occupation are Helper, Laborer, Post Framer, and Construction Worker.

Perform tasks involving physical labor. There are around 2,900 of these workers in Motor Vehicle Body and Trailer Manufacturing. They operate hand and power tools of all types. You will find these workers preparing sites, digging trenches, erect scaffolding, applying paint to surfaces, sealants and assembling structures. Common job titles for this occupation are Helper, Laborer, Skill Laborer.

Operate cutting and grinding equipment. Roughly 2,400 of these workers are found in the motor vehicle body and trailer manufacturing industry. They fabricate position and fit parts of structural metal products. Due to handling sharp metal, cut-resistant gloves are must-have safety gear. Common job titles for this occupation are Fitter, Layout Main, and Tack Welder.

Repair or overhaul mobile equipment. There are roughly 8,000 of these workers found in Trailer Manufacturing. You will find these workers replacing worn parts and reassembling equipment using hand tools. Common job titles for this position are Heavy Equipment Technician, Field Mechanic, and Equipment Mechanic.

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 2,100 members of this occupation in motor vehicle body and trailer manufacturing. You will find these workers aligning metal parts and grinding out burrs or sharp edges. This makes cut-resistant gloves a high priority for this worker. Common job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, and Press Punch Operator.

keep machines, mechanical equipment, or the structure of an establishment in repair. There are around 1,800 of this occupation working in Motor Vehicle Body and Trailer Manufacturing. You will find these workers pipe fitting, repairing equipment, and repairing buildings. Job titles for this position are Maintenance Worker, Maintenance Mechanic, and Facilities Manager.

Operate machines to coat or paint a wide variety of products. Examples include cloth, glassware, cloth, copper, ceramics, metal, plastic, paper, wood, silver, and rubber. There are around 1,400 of these workers in body and trailer manufacturing. You will find these workers mixing ingredients and cleaning production equipment. Noise levels are a concern for these workers. Common job titles for this occupation are Coater Operator, Paint Technician, Silk Screen Operator, and Spray Painter.

Commercial transportation equipment, such as trailers and truck bodies, use a lot of steel and aluminum in their production. Where there is steel, you can bet welding is taking place.

As we point out on our Welding Protection page, trailer manufacturing employs some of the highest numbers of welders in any industry. This definitely impacts the type of work performed in this industry.

Here are just a handful of the hundreds of activities performed each day across this industry:

Many of the activities found in the automotive industry involve metal fabrication. Be sure to check out our Metal fabrication industry page for more information and resources.

One thing is crystal clear: work performed in this industry is dangerous. Out of all automotive industries, this is the most dangerous one. Take a look at the table below; it shows BLS industry incident rates for this industry.

| Sub-Industry | NAICS # | # of Incidents for Every 100 Employees |

|---|---|---|

| Motor home manufacturing | 336213 | 8.7 |

| Travel trailer and camper manufacturing | 336214 | 8.6 |

| Motor vehicle body and trailer manufacturing | 3362 | 7.4 |

| Motor vehicle body and trailer manufacturing | 33621 | 7.4 |

| Truck trailer manufacturing | 336212 | 7.3 |

| Motor vehicle body manufacturing | 336211 | 6.4 |

Welding in itself is one of the most hazardous processes found in any industry. Combine that with a lot of metal that easily lacerates a worker’s hands, chemicals that burn, accumulations of potentially hazardous dust, and unpredictable flying projectiles, and you can understand why injury rates are high.

Things are changing rapidly within this industry. We live during a point in time where semi-trailers will soon be driving themselves, without an operator, delivering goods from point A to point B. As technology transforms this industry, safety and PPE will also have to adapt.

At MCR Safety, we are continuously adapting our line of PPE to match workers’ needs. So, regardless of where technology takes this industry, we will be there protecting workers. We protect people!

Let MCR Safety keep you safe when manufacturing trailers.

Find the right MCR Safety product that protects you against these common hazards.

Assembling metal trailers require flexible yet abrasion-resistant gloves.

Anytime you're working around metal, it only makes sense to wear the best cut-resistant PPE. An added bonus is wearing HiVis orange, allowing quick identification of workers. Choose the proper PPE to protect your arms.

Trailers come in a wide range of colors. Mixing these colors requires lightweight chemical-resistant gloves. Check out our Chemical Permeation Guide for specific chemical breakthrough times.

Learn More About Chemicals and Liquids Protection

A barehand feel is what most workers prefer, yet have been denied in the name of safety. With today’s advanced fiber technology, you can feel what you were meant to feel all along, but with the cut protection you require. When it comes to assembling hydraulic engines for trailers, MCR Safety has you covered in this industry. Be sure to check out our Cut Protection Page for additional information.

Learn More About Cut and Sense of Touch Protection

Building trailers involves work conditions where only the best PPE will suffice. From hydraulic fluids to building small engines to installing axles for trailers, workers prefer PPE that hides dirt and keeps them protected.

Exposure to heat is all too common for metal fabricators. Hot tools, hot machine parts, and hot metal are always a concern. Be sure to check out our ITC Heat Resistant blog.

Grinding out a metal tong for a trailer requires the best safety glasses and face shields.

Handling metal parts will quickly lacerate your hands, and a trailer has a lot of metal parts.

Spray painting the trailer exposes workers’ hands. Some nice Grippaz gloves should be your ticket to clean, dry hands!

Learn More About Painting Protection

Banging metal around is what workers do in this industry. Check out our high-dexterity, high cut-resistance, and back-of-hand protection.

Metal splinters, small metal chips, and burrs are found all over the metal pieces. It might be smart to wear some high-rated ANSI puncture gloves. Check out our blog on Top Puncture Resistant Gloves.

Learn More About Puncture Protection

Trailer manufacturing workers assemble axels and suspensions. Their hands can quickly get injured from sharp metal edges and jagged surfaces.

Welders need shaded eyewear when cutting and grinding, or when exposed to searing rays. Be sure to check out our Welding Protection page for more information.

Learn More About UV Radiation Protection

With over 20,000 welders working in trailer manufacturing, welding safety gear is a high priority. There is always the risk of burns or coming into contact with hot objects for welders. Be sure to check out our Welding Protection page.

Learn More About Welding and Cutting Protection

Welding fuses steel pieces together on trailers, which means there is always sharp metal close by. We offer cut-resistant liners in several of our styles. Be sure to check out our Welding Protection page for more information.

Learn More About Welding Sharp Objects Protection

Sparks can burn through cotton or synthetic work shirts, causing the material to combust. With leather welding gear, you've got the protection you need when welding a trailer together. Be sure to check out our Welding Protection page for more information.

Learn More About Welding Sparks Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.