I was training to be an electrician. I suppose I got wired the wrong way round somewhere along the line.

~ Elvis Presley

Like Elvis, MCR Safety got its start in the great city of Memphis. And, similar to Elvis, we impact people, such as electricians, all over the world. Our impact is made through our safety equipment – we leave the singing to the professionals.

MCR Safety is dedicated to keeping workers safe, protected, and informed! With that focus, we work hard to keep users aware of both the PPE we manufacture and how it is used across specific industries. When you have an important purpose like ours, protecting workers, there is no other choice. At MCR Safety, we are driven by our motto: We Protect People!

Einstein once said, "Education is not the learning of facts but the training of the mind to think." We want you to think about your safety at work, not just remember product facts like cut scores, yarn gauge, or ARC ratings! To help with this, we've created a central place for all things safety-related that pertain to the Electrical industry.

You may opt to continue reading to learn more about electrical contractors, electrical occupations, and the electrician's daily work activities; or, you can simply click the hazard warning icon and be taken directly to the safety section for this industry, its suggested PPE, and potential hazards.

When our homes blow fuses or our electric gadgets require more power, we will likely call a professional to fix or upgrade the wiring. Electricians keep our homes flowing with energy! It is this highly skilled tradesman who installs, maintains, and repairs electrical wiring and equipment.

According to the Bureau of Labor Statistics (BLS), electrician jobs numbered about 666,900 in 2016. The good news is, that number is expected to grow by 14% over the next 7 years.

Virtually every commercial and residential building has electrical power installed during construction. With interest rates remaining low over the past decade, construction projects have increased, and the installation of electrical power is in high demand. This ultimately means there is no shortage of work for skilled electricians who can fill this need.

The U.S. NAICS industry code for Electrical Contractors working in construction is 238210. This coded number allows the government to classify all the sector's business activities, helping workers and suppliers better understand the industry. Within the construction industry, 465,220 electricians find employment.

According to IBISWorld, electrical contractors produce over $185 billion in economic activity each year. More than 219,000 electrical businesses operate in the U.S. These are the companies responsible for installing all wiring throughout buildings, connecting customers to power, light, and communication systems. One unique aspect of the industry is that no one company controls more than 5% of the market, which means small businesses thrive as electricians. Some of the largest companies operating in the electrical industry are Quanta Services, EMCOR, Service Electric , and Cupertino.

Every industry typically has associations and organizations that promote all companies' general welfare and support workers operating in the industry. Here are two of the most recognized associations for electrical contractors:

Independent Electrical Contractors

This association boasts 53 educational satellite offices across the U.S. They are one of the electrical industry's primary advocates, bringing education and resources to 3,600 members nationwide.

Water Leak Glove Test

Water Leak Glove Test

National Electrical Contractors Association

This group gives a voice to the 70,000 electrical firms employing contractors across the U.S.

Water Leak Glove Test

Water Leak Glove Test

All electrical associations have one thing in common: they work to keep electricians armed with the most relevant, up-to-date information possible to help them best perform their job. Many electricians working in this industry look to these professional associations for answers.

What type of certification does an electrician need? Every electrical contractor operating in every U.S. state requires a license before performing electrical services. However, each state does have different requirements. Some states require an additional exam to be passed, proving that certain skill sets have been mastered. Other states, such as California, require at least 8,000 hours of real-world experience as an apprentice to become a Journeyman. You can find information about the requirements of each state using this link .

The certification requirements don't apply to only master electricians; apprenticeships require a certificate before beginning work. Generally speaking, there are two paths to learning all the knowledge necessary to perform electrical work activities: a trade school or community college.

How long is electrician school? Similar to the different requirements for certification in each state, the length of trade school programs also depends on the state and the school the student selects. Most schools average between 500 and 1200 hours before one is eligible to receive a diploma. Many trade schools will transition students into an apprenticeship program, where they will learn from the current masters of the trade and spend 4-5 years in-classroom study.

Electrician programs teach the student a wide range of electrical topics . Here are some of the most common principles taught:

Most students find their career choice to be rewarding once the schooling phase is complete. It's an industry that will never fade into oblivion, as the world is tethered to electricity.

How much does an electrician make? On average, the Bureau of Labor Statistics (BLS) shows that electricians make a little over $56,000 a year. Having a steady income is one of many bright sides of being an electrician. Another pro to becoming an electrician is the growth expected for the industry. Our world is increasingly seeing more electrical tools and technology being developed for everyday life. Consider, for example, electric charging stations as more and more vehicles transition to electric energy.

However, as with any profession, there are tradeoffs when selecting a specific career path. Many potentially interested individuals see the number of years in school and the amount of in-field experience required as major cons to becoming an electrician. Another drawback is the level of danger of the work performed. As we highlight on our Electrical Arc page , burn injuries from arc flash hazards are life-changing injuries that all electrical contractors face.

According to the BLS, there are over 932,000 workers finding employment in the Electrician Contractor sub-industry, NAICS 238210. Over half the workers are electricians, with 465,220 employed. However, 467,000 additional workers find work across this specific construction sub-industry.

Here are the top five other types of workers that need PPE, outside of electricians:

Helpers-63,300 – assist electricians by holding materials and tools and being an extra set of hands.

Construction Laborers-18,310 – perform physical labor

Telecommunications Installers-17,900 – install telecommunications cables

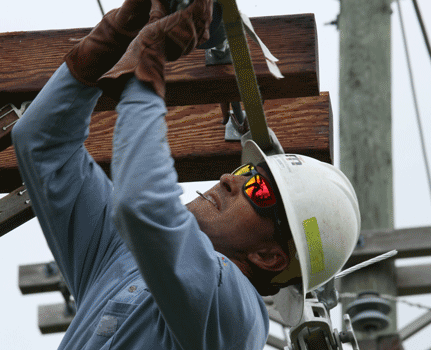

Power-Line Installers-5,350 – erect power distribution systems

Material Movers -4,650 – transport construction material across work sites

All the above workers have one thing in common. Each of them relies on safety supplies to protect them from workplace hazards.

As shown in this image, many trades start off as apprenticeships

As shown in this image, many trades start off as apprenticeships

Hoovers reports that 80% of electrical contracting firms have fewer than 10 employees. The employees working can be categorized into one of these five occupations:

These electricians work in commercial buildings, on construction sites, and on mechanical electrical systems. Offices, restaurants, and shopping malls are examples of commercial buildings. Commercial electricians can be found performing electrical repairs or installing equipment, security systems, and electronic key systems.

What is a journeyman electrician?These electricians work with lighting installations, mechanical systems, security systems, and power supplies in both residential and commercial buildings. Many journeymen electricians are found working in construction.

These electricians are different from commercial electricians because they work in industrial operations such as factories, plants, and mines. They install, maintain, and repair industrial electrical equipment and electronic controls.

What is a master electrician? These electricians are highly skilled electricians. Most are in a supervisory role over a staff of laborers, apprentices, and journeymen. They typically own a contracting business. To even be considered as a mater electrician, a minimum of seven years of experience is required in most states.

These electricians work in apartments and houses. They install, maintain, and upgrade electrical equipment in residential spaces.

As we highlight in our article Electrical Contractors and Lineman Jobs , not all electricians are the same. Yes, all electrical workers are operating around electricity; however, some focus on lineman work and others as electrician technicians.

So, what's the difference between the technician and electrician? Simply put, the technician works on electrical devices that harness the power of electricity. You will find many of them installing and maintaining electrical equipment in buildings, such as new residential homes. On the other hand, electricians are responsible for designing the electrical plan for a building and installing all the wiring that provides power to the electrical equipment a technician may install. Both workers find employment in construction. As we highlight in our article Construction Phases , the electrical contractor performs the rough-in work, around Stage 3 of a construction plan, by wiring outlets. The technician shows up around Stage 5 to install appliances and mechanical devices that will use those outlets.

What do electricians do? Electrician work involves repairing and servicing existing electrical systems to retrofitting and installing new systems, electricians carry out many activities. For the most part, though, electrical work revolves around new construction, both residential and nonresidential. While there are similar tasks required with both the installation of new electrical systems and the maintenance of existing systems, there are some important differences between the two.

New Construction

Installing electrical systems in new construction is considered less complicated when compared to ongoing electrical maintenance of existing systems. Installing new electrical systems in residential construction can be broken down into 5 steps:

1. Temporary electricity provided -a temporary electrical pole is installed to operate machinery needed on-site.

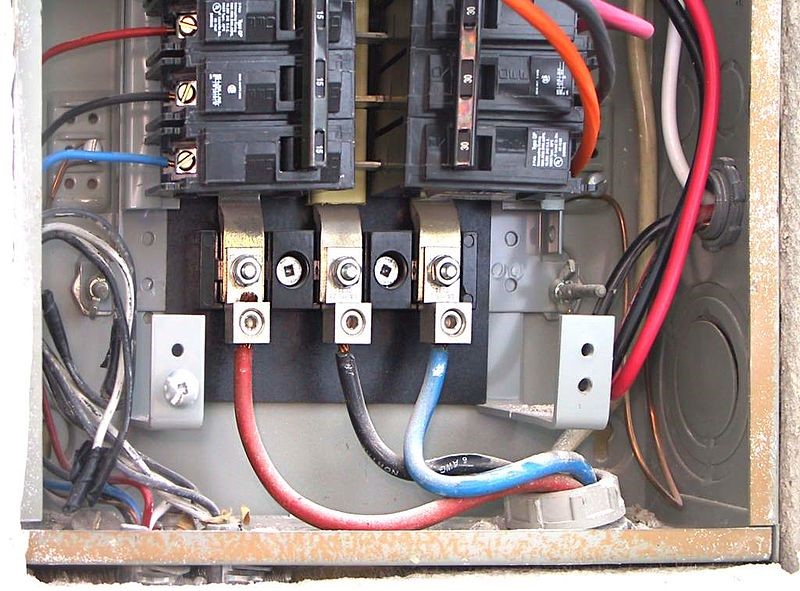

2. Rough-in-circuit wiring is installed between the electric box and wall studs. All the floors, windows, and doors have been installed by this stage, only the sheetrock is left.

3. Temporary additions-receptacles and switches are temporarily installed.

4. The finish-all switchboards, receptacles, lights, and fans are installed.

5. Testing-wiring is properly checked and adjustments made as needed.

Maintaining

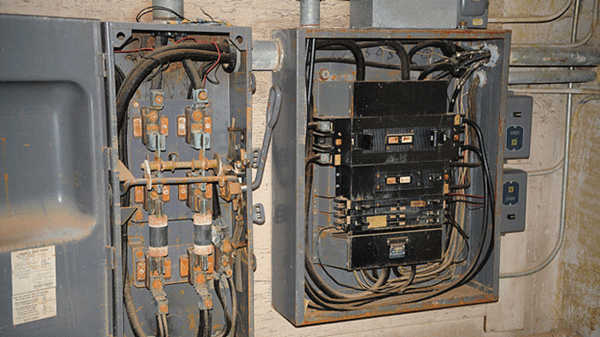

Maintaining electrical equipment is a little more complicated. Electricians must identify the source of electrical problems and repair broken equipment. This may include replacing parts, light fixtures, or motors.

Electrical Activities

An electrician's toolkit carries a wide assortment of tools. Electrical contractors require a handful of specialized tools, including the correct safety equipment.

Here are the tools electricians utilize to carry out the activities listed above:

Here are some events and situations where electrical hazards exist when completing the above activities:

The hazards classified as arc flash hazards may exist even when equipment is in an enclosed condition. Most of the tools electricians utilize can easily make contact with power lines, increasing the likelihood of electrical shock. From cranes and metal ladders, workers on a construction site must always be on guard against electrical injuries.

In 2018, over 10,000 attendees visited the NECA convention, which is considered the largest electrical construction trade show in the U.S. Guess what product and service over 40% of them said they were interested in learning more about during their visit? Answer: Safety Equipment and Apparel.

It makes sense that so many attendees answered the way they did. When you’re working around electricity and energy sources, there is no off day. Working safely is an every day requirement, otherwise you’re going home injured, if you’re lucky enough to go home at all.

Working without the right PPE greatly increases the likelihood of possibly catastrophic injury, doing it right every day is a must, otherwise, injuries are not far behind.

Potential injuries to electricians include electrical shocks, burns, and cuts. With over 2,000 people admitted to hospital burn centers yearly with severe arc-flash burns, electricians count on MCR Safety to provide PPE to keep them safe. Within the construction industry, the overall rate of injuries per 100 electricians is less than the average across all industries. See the table below:

| Industry | Occupation | NAICS | Incidents per 100 Employees |

|---|---|---|---|

| Building equipment contractors | Electrical contractors and other wiring installation contractors | 23821 | 2.7 |

Keep in mind, however, when there is an injury, the consequences are severe. In order to stay safe at work, electricians must wear the proper PPE to protect themselves from hazardous working conditions. Protection includes wearing ARC-rated safety vests, FR coveralls, FR shirts, and high-quality cut protection.

Working safely is an everyday requirement if you want to escape going home injured. You have the POWER to protect yourself! At MCR Safety, we perform one function every day for a multitude of industries: Protecting People! Let us help you protect yourself on the job the right way and keep you protected for years to come.

How dangerous is it to be an electrician? Accidents and injuries are common across the construction industry. What fools many people is that the injury incident rate is not that high for electricians. Electrical contractors rank #14 out of 20 total construction sub-industries for injury incidents. However, more workers are found across this industry than other construction sub-industries, which lowers the overall average. When you review the stats below, you'll see some rather alarming injury numbers. So, to answer the initial question above, electrical work is dangerous.

For every 100 people, there is an injury experienced by 2.2 electrical contractors. Here are some other stats the BLS provides that electricians should consider:

Electricians work around a lot of metal, causing increased numbers

of cut injuries.

Electricians work around a lot of metal, causing increased numbers

of cut injuries.

Here are some events, activities, and situations where electrical hazards exist on the job:

The hazards classified as arc flash hazards may exist even when equipment is in an enclosed condition. Most of the tools electricians utilize can quickly make contact with power lines, increasing the likelihood of electrical shock. From cranes and metal ladders, workers on a construction site must always be on guard against electrical injuries.

Is being an electrician hard? We know an electrician's work is dangerous; however, being hard probably is answered differently by everybody. At MCR Safety, we design PPE to help protect workers on the job and we know our task is valued by customers. In 2018, over 10,000 attendees visited the NECA convention, which is considered the largest electrical construction trade show in the U.S. Guess what product and service over 40% of them said they were interested in learning more about during their visit? Answer: Safety equipment and apparel.

With so many users mentioning PPE, one must conclude electrical work is definitely dangerous. When you're working around electricity and energy sources, there is no off day. Working safely is an everyday requirement. Otherwise, you're going home injured, if you're lucky enough to go home at all.

To combat the potential injuries electricians may suffer, they look to MCR Safety to protect them with high-quality PPE. Here is a broad list of various PPE that MCR Safety supplies to help electricians avoid injury:

We've highlighted a lot of information about electricians and electrical technicians and thrown a bunch of industry stats at you. The remaining part of this page showcases some of the most common electrical hazards workers face and the different PPE options electricians should consider wearing while performing their work.

You might be interested in checking out our other dedicated construction sub-industry pages. Our entire construction industry home page can be found by clicking the below image.

Find the right MCR Safety product that protects you against these common hazards.

Temperatures reach as high as 35,000°F during arc blasts. We now manufacture vests, gloves, and rain suits that are ARC-rated.

Learn More About Arc Flash Protection

We know many electrical activities require all three. We now manufacture several styles with cut-protection, abrasion-protection, and arc-protection wrapped up into one glove solution!

Tremendous hand dexterity is required when splicing and pulling wire, placing conduit, wiring electrical boxes, or working around metal junction boxes. Our 18-gauge featherweight gloves are an excellent choice for wiring.

Learn More About Cut and Sense of Touch ProtectionElectricians work indoors and outdoors. Safety glasses that are dielectric, made with no metal parts and made for I/O, come in handy when on a job site.

Learn More About Dielectric and Indoor Outdoor Protection

Keeping glasses easily wrapped around your hard hat can create hazards in itself, in addition to causing discomfort. Our DM3 eyewear styles have wire adjustable temples, designed to put limited pressure on your ears.

Learn More About Eyewear Adjustability Protection

Body heat raises the likelihood that glasses will become fogged. Were you aware that MCR Safety makes our 6X greater fog-resistant glasses in a polarized version?

Learn More About Fogging Protection

Electricians work in confined areas, which means bumping up against equipment is always a concern.

Learn More About Impact Protection

For electricians working around live energy, coming into contact with electric arc and arc flashes is a definite risk. In addition, there is also blowing debris, flying chips, and projectiles present when using an electrician's drill.

Learn More About Impaired Vision Protection

Electricians are always moving materials from point A to point B. Our ARC-rated leather gloves, double-stitched with DuPont™ Kevlar®, are the ideal choice for electricians.

MCR Safety’s lineup of grabbers and glove clips will keep one of the most forgotten pieces of PPE, your gloves, close by when needed.

Electricians rely on precision while working. We manufacture some of the lightest weight gloves, with high abrasion-resistance and excellent sense of touch.

Learn More About Sense of Touch Protection

It's always smart to keep a pair of cut-resistant gloves on-hand when installing lighting systems, fastening metal boxes to walls, cleaning up the work site, or replacing receptacles and ballasts.

Learn More About Sharp Objects Protection

Electricians work outside and are regularly exposed to the sun. Our FR shirts are designed to keep your arms covered and protected. Having some polarized glasses nearby also makes sense.

Coming into contact with overheated electric equipment is always a concern. Read up on Heat-Resistant Gloves and know how our ITC lab reports heat ratings.

Learn More About Thermal Burns Protection

Staying seen on a construction site is a must. For electricians, we’ve got ARC-rated safety vests available to keep you seen and protected from arc blasts.

It is not uncommon to find some electricians wearing non-FR clothing, which can easily ignite and provide an additional fuel source, increasing burn injuries. MCR Safety ensures its FR clothing is ARC-rated.

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.