If you're yearning for the good old days, just turn off the air conditioning.

~ Griff Niblack

Next time you are having a bad day and sweating in the hot sun, just remember something important. There was once a time cooling down was not so easy. Take a moment to sit in a cold room and allow that cool air to make your world a little more comfortable. Taking it one-step further, remember Willis Carrier, "The father of Air Conditioning". In 1902, Carrier developed engineering drawing that address air condition functions like temperature control and air circulation. The air conditioner is considered by many one of the most important inventions of modern times.

On this industry page, we cover a wide range of construction HVAC topics: the industry, HVAC Basics, system types, employment and occupations, work activities, tools, and safety hazards. You may opt to continue reading to learn more about drywall, or you can click the hazard warning icon and be taken directly to the safety section for this industry, its suggested PPE, and a list of potential hazards.

What does HVAC stand for? The acronym stands for heating, ventilation, and air conditioning, representing the system that heats and cools buildings. The most appropriate HVAC definition comes from Davis Air Conditioning and Heating , which describes it as the term that classifies all equipment that controls a building's temperature and keeps indoor environments comfortable.

The U.S. NAICS industry code for HVAC Contractors working in construction is 238220, which also encompasses those operating as plumbers. This coded number allows the government to classify all the sector's business activities, helping workers and suppliers better understand the industry. Within this construction sub-industry, over 1.1 million , workers find employment; HVAC/Plumbing is one of construction's largest overall industries.

According to IBISWorld, HVAC contractors produce over $85 billion in economic activity each year. Over 111,000 HVAC businesses operate in the U.S., and these companies are responsible for keeping people cool in the summer and warm in the winter. One unique aspect of the industry is that no one company controls more than 5% of the market, which means small businesses thrive as HVAC contractors. Some of the largest companies operating in the industry are Comfort Systems, Emcor Group, and Trillium Facility .

Today's modern HVAC industry maintains comfortable temperature in commercial offices, data centers, hospitals, laboratories, nursing homes, refrigeration units in restaurants, residential homes, schools, factories and numerous other facilities. They allow mankind to store and transport food, medicine, and other perishable items.

The US is by far the largest user of air-conditioning across the world. Only 11 percent of households in Brazil use air-conditioning and 2 percent in India. Compare these numbers to 87% of households in the US that use air-conditioning. Obviously, there is great demand for technicians to keep heat and air flowing, which we cover more in-depth below. It also means there is a great demand in ensuring these worker stay safe, which we cover more in-depth too.

Where you live plays a big part in either keeping a building hot in cold weather or cool in summer months. Some parts of the country require more cooling, whereas other requiring more heating. See the department of energy's climate zoning below to the right. You can also find the Department of Energy guide for more information.

Keep in mind though; controlling temperatures is not a new concept. Modern people are only fortunate to have electricity powering the air we can't live without. People for centuries have been cooling and heating their homes.

Even though Carrier developed the modern day version of HVAC, circulating a room's air temperature has been with us since antiquity. The Roman's maintained a furnace system that heated the air. The floor was elevated above the ground by pillars called pilae, allowing hot air to circulate under it. This in turn would keep home residents warm during cold winter months, essentially, what our modern day HVAC units provide today. History repeats itself, only repeating itself today with electrical based systems.

Here are some other clever ways A/C has been produced over the years:

Cave dwellers-used caves to shield them from the heat

Egyptians-hung wet reeds in the window to keep a cool breeze flowing though the rooms.

Chinese-used hand-held fans

Victorian-used high ceiling and deep porches

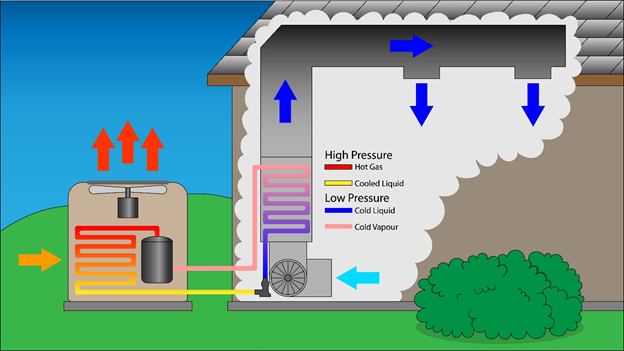

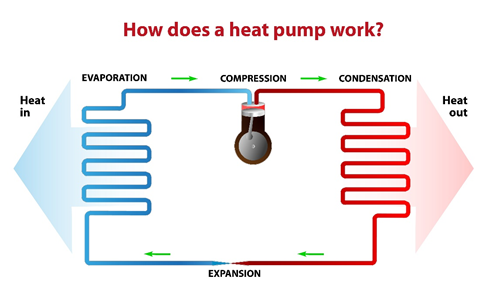

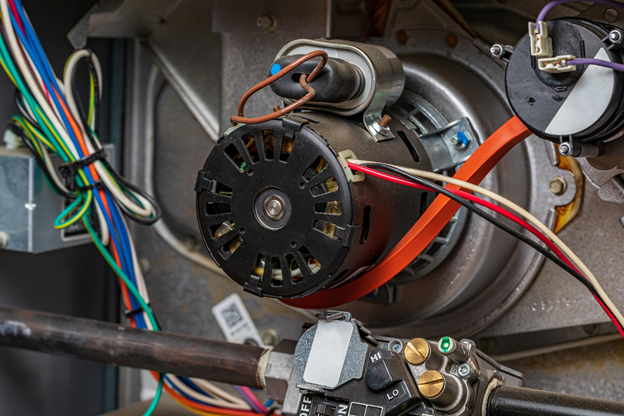

How does HVAC systems work? It all starts on the outside of a building. Utilizing electricity, the outside HVAC unit sucks outside air into the system and passes it through a filter to remove dust and debris. In conjunction with the compressor that moves Refrigerant, the unit's condenser coils cool the outside air. Once cooled, that air is transported throughout a building via its ductwork system and blows out of vents. While the unit blows the cooled air inside, it also sends the hotter air outside (see the image above). The thermostat processes the room's ambient temperature and tells the unit how hard to work and at what temperature the room needs to feel.

The central heating system utilizes heating machine, such as a furnace that heats the inside of buildings. All systems have a burner for burning fuel, heat exchangers, a blower, and a flue.

Useful sites for better understanding how an HVAC system works:

What is a HVAC system? There are several different types of HVAC systems available. They accommodate different weather conditions and building sizes.

Here is a breakdown of the most common types you'll find operating:

Split System-As the name suggests, this approach breaks up the system into two units: the outdoor unit holds the condenser and compressor. The indoor unit contains the evaporator coils. This type of system allows indoor units to be shielded from outdoor weather.

Ductless-Designed to fit in all types of spaces , this system features a single condenser. It's our above image for this section.

Zoned System-For systems covering multiple areas of a building, this system allows for custom temperatures in numerous rooms.

Packaged Units-This system houses every component needed to both cool and heat a building in one unit, avoiding the need for both an outside unit and a furnace. These units save space, are easier to install, and are quieter to run.

Heat Pumps-These single units heat and cool a building. Our earlier example of how HVAC works is describing a single unit.

Dual Fuel Heat Pump-In especially cold environments, this system utilizes a natural gas furnace in combination with the heat pump when temperatures drop below 35 degrees.

What size HVAC system should I use? Due to limited space, smaller HVAC units are used mainly on buildings without a basement or crawl space. And, it's important to remember that bigger doesn't necessarily mean better. If a unit is too big, it can produce increased condensation, lowering the overall comfort experience. There are selection tools that will help you determine the appropriate size unit based on the part of the country you live in and the heating/cooling needs of a particular space. Some parts of the country, such as southern states, will require a 2-ton system. Because moderate winter conditions are experienced in the south, larger units are often not needed as they do not have to heat as much. Those who live in colder areas will require a 5-ton system.

Useful websites for understanding and comparing different systems:

Heating, air conditioning, and refrigeration installers, mechanics and technicians are those working professionals that control the temperature and air quality in buildings. Across the US there are roughly 332,900 HVACR technicians working on heating, ventilation, cooling, and refrigeration systems. According to the (BLS) Bureau of Labor Statistics, HVACR technicians are expected to grow 15 percent from 2016 to 2026.

You will find HVACR technicians working on HVAC systems in commercial, industrial and residential establishments. These can be located in residential construction, homes, hospitals, hotels, research laboratories, schools, office buildings, and factories. With weather conditions different across the US, as shown above, some technicians may find themselves working in hot areas or extreme cold areas.

The HVAC industry is provides a skilled trade for many and equipment manufacturing for numerous companies. Each January, over 49,000 people attend the AHR Expo , a testament that there are lot of people working across the HVAC industry.

Around 64% of all HVACR occupations are Plumbing, heating and air-conditioning contractors. Here is a breakdown of HVAC workers:

| Employment Source | % Employment |

|---|---|

| Plumbing, heating, and air-conditioning contractors | 64 |

| Self-employed workers | 9 |

| Educational services; state, local, and private | 4 |

| Retail trade | 4 |

| Wholesale trade | 3 |

HVAC Installer-You will find this worker installing, repairing, replacing and maintaining HVAC system. Installers often are working in confined space and uncomfortable environments.

HVAC Mechanic-You will find this worker performing maintenance and servicing repairs on heating, ventilating, and air conditioning systems

HVAC Service Technician-You will find this worker providing preventative care and repairs for HVAC systems.

AC Technician-these technicians focus on cooling systems. Many AC technicians will work as independent contractors.

Refrigeration Technician-focus on the one area of refrigeration, when temperatures are below 60°F, whereas any cooling above involves AC technicians.

The HVAC industry is filled with career opportunities. However, before any individual can begin their rewarding career choice, they must finish school and become certified.

With the complexity of the technology being utilized in modern HVAC systems, becoming certified is no longer a choice. Certification shows that the HVAC tradesman is qualified and has the necessary knowledge to handle any HVAC-related problem thrown their way. A certificate is a strong indication of a worker's competency within the field.

Here is a list of standard HVAC certificates technicians may complete:

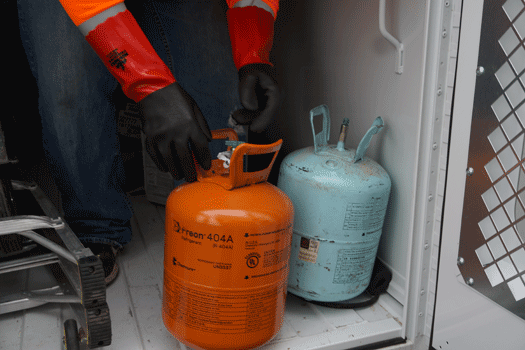

EPA Type I Certification-for working with and servicing small appliances requiring less than 5 lbs. of Refrigerant

EPA Type II Certification-required for servicing high-pressure appliances

EPA Type III Certification-indicates training for servicing low-pressure systems

EPA Certificate-focuses on correct refrigerant handling

North American Technician Excellence (NATE)-the most prominent certification organization for technicians

All contractors operating across every U.S. state require a license before performing heating and air-conditioning services. However, each state does have different licensing requirements. Some states require passing additional exams after the completion of trade school classes.

You can find information about the HVAC licensing requirements of each state using this link .

Useful websites for those exploring certification options:

As with all higher-level education, there are multiple routes an individual can take to become trained and certified in the HVAC field. Depending on the path chosen, school and training programs may range anywhere from six months to five years . So, the most critical question revolves around what each approach entails.

What to look for in HVAC schools? Here are the options individuals have in learning the craft:

Apprenticeship-Learning alongside a Journeyman technician allows individuals to gain hands-on experience, but this path takes the longest time at up to five years.

Associate Degree Programs-These programs, often available at local community colleges, teach HVAC fundamentals and typically take around 18-24 months to complete.

Trade School-The shortest path to HVAC training, enrolling at a trade school allows students to be in the field within 6-12 months. Trade schools teach hands-on situations, ensuring workers are ready for an entry-level role. Even though this path requires the shortest amount of time spent in a classroom setting, individuals will still require another two years in the field to become proficient at what they do and before they can work independently.

HVAC schools teach the student a wide range of subjects related to heating, ventilation, and air-conditioning. Here are some of the most common principles taught:

Online schools are another option to consider. These programs allow more flexibility, as students can study when they want to as opposed to attending classes on a set schedule. Penn Foster and Ashworth College are examples of online programs.

Useful websites for understanding HVAC trade schools:

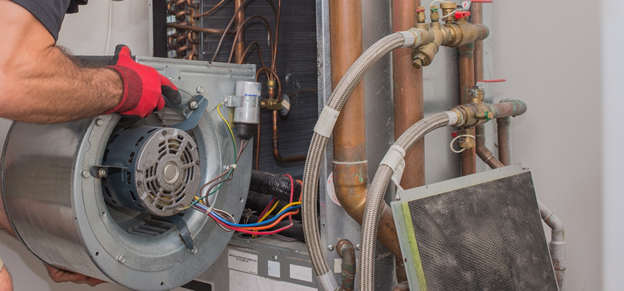

You will find HVAC installers, mechanics and technicians performing a wide range of tasks. Here are some everyday activities HVAC occupations perform:

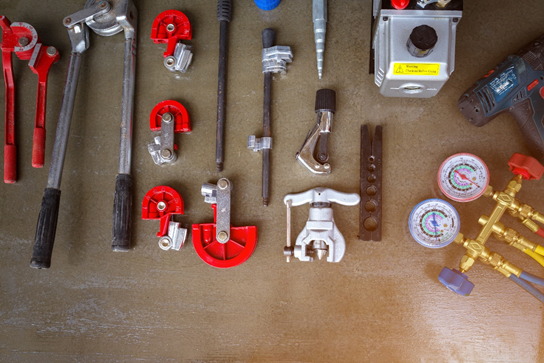

HVAC technicians use a wide range of tools and equipment. Here are some of their everyday equipment and tools:

HVAC workers used a wide range of materials to keep systems up and going. Here is a brief look at the most common used.

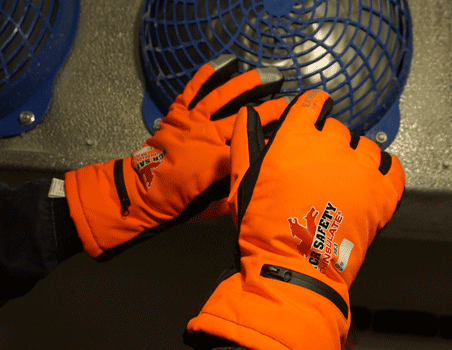

Depending on the materials used, a HVAC contractor will need to change the type of PPE used. An example includes touching sharp objects, which shouldn't take place with disposable.

Don't learn safety rules by accident!

HVAC hazards exist, and you do not want to learn about them the hard way.

When you look at the percentage of injuries experienced, HVAC contractors rank #7 out of 20 total construction sub-industries for injury incidents. For every 100 people, 3.5 injuries occur. However, due to the number of workers found in both plumbing and HVAC, there are over 13,000 total injury cases. The vast amount of injuries that occur ranks this sub-industry as the highest across all construction for on-the-job injuries. It's the most dangerous sub-industry in construction

Here are some other alarming stats the BLS provides that plumbers and HVAC contractors should consider:

With increased awareness around the hazards that cause the most injuries, you're now ready to consider protection. Workers can minimize the job threats faced, and the best defense is to wear the correct personal protective equipment (PPE) for the job.

Now, let's illuminate what types of personal protection HVAC contractors and technicians require when installing and repairing systems. As the injury stats mentioned above show, workers face the risk of injury every time they perform work. Simply handling sheet metal can easily lacerate one's hands, which is why wearing appropriate cut protection is extremely important. Also, there is a concern when handling liquids and refrigerants, making chemical-resistant gloves necessary.

To combat potential injuries workers may suffer, they look to MCR Safety to protect them with high-quality PPE. Here is a broad list of various PPE that MCR Safety supplies to help workers avoid injury:

Workers want to stay safe but also be comfortable. Installing ductwork throughout hot attics during the summer is no joke, which is why we've introduced many lightweight, breathable, moisture-wicking products in recent years.

598RJH Breathable Rainwear

598RJH Breathable Rainwear

We've highlighted a lot of HVAC information and provided a bunch of industry stats. Now, the remaining part of this page showcases some of the most common HVAC hazards, and the different PPE options workers should consider wearing while performing their work.If you prefer to return to the main Construction home page, click the image below. From the home page, you'll be able to access any of the numerous construction industries we cover.

MCR Safety's dedicated Construction Industry resource page.

Find the right MCR Safety product that protects you against these common hazards.

Metal is used all over HVAC units, which means pipes and surfaces easily rust in wet conditions. Combine that with general maintenance and insulated tubing, abrasive conditions are ever present.

Refrigerant runs throughout copper. When brazing copper, high temperatures are reached. Makes sense to keep some hand protection nearby.

Chemical treatment of water for cooling and heating systems requires some protection. Moreover, chemicals can easily squirt out of a cylinder. Our Predastretch is flexible and chemical resistant, the perfect solution for handling refrigerant.

Learn More About Chemical Protection

HVAC workers most times find themselves working in confined spaces. Operating powered pneumatic and hydraulic equipment will quickly injure hands during maintenance activities around sharp metal.

Learn More About Cut and Crush Protection

Commercial filters have to be changed every 90 days. Replacing dusty filters requires sealing your eyes.

Learn More About Dust Protection

Excellent grip is required, since slippage when handling materials and tools greatly increases the potential for injury. Check out our lightweight FLT and BNF breathable coated gloves with Nitrile coatings for superior grip!

Learn More About Grip Protection

Anyone maintenancing a heat exchanger knows that heat protection is required due to an increased possibility of burns. Hot components while performing regular maintenance is a definite concern. Check out our blog on ITC Lab’s Heat resistance.

Learn More About Heat Protection

When installing equipment, repairing parts, and fabricating material is always hazardous. A lifetime eye injury can easily occur when HVAC system’s fastener comes off and hits your eye. Combine that with splashing chemicals and refrigerants; HVAC workers definitely require some protective eyewear.

Learn More About Impaired Vision Protection

HVAC units may control a part of what Mother Nature does, keeping the climate cool. However, it does not control when Mother Nature decides to rain or snow. Rainwear is essential and a set should always be close by.

Learn More About Inclement Weather Protection

Keeping restaurant refrigerators and coolers operating is an everyday part of the job.

Learn More About Insulation Protection

The CL4 eyewear style is equipped so earplugs serve as the eyewear lanyard. Click below to download instructions on how to insert earplug cord onto eyewear temples.

Learn More About Noise Protection

Construction sites are hectic and busy. Be sure to stay seen.

Learn More About Overall Visibility Protection

As one technician told us, "I've got to be able to feel my screws". Most HVAC workers prefer featherweight protection when electrical wiring and holding small parts . Did you know we make featherweight cut protection?

Learn More About Sense of Touch Protection

Working with a duct take off exposes a workers hands to sharp metal. Servicing contractor’s hands can easily get sliced up around sheet metal. Duct work exposes workers to extreme cut hazards and replacing filters can easily cut up one’s hands. Cut resistant gloves should be worn when handling anything that could lacerate you such as sheet metal.

Learn More About Sharp Objects Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.