The road to success is always under construction.

~ Lily Tomlin

Nothing could be more accurate when considering the building, operation, repair, and maintenance of the more than 4 million miles of roadways in the U.S. Almost everyone who finds themselves traveling in a vehicle will likely see a roadway worker at some point in their drive. Why? It's because roads are continually needing maintenance, from fixing potholes to adding new asphalt. Bridge, road, and highway construction and maintenance workers are the individuals that make our road travel possible.

Bridge and Roadway Construction

Highways, bridges, and roads play a significant role in the construction industry and the nation’s overall economy. Dwight D. Eisenhower recognized the importance of roads when he addressed Congress back in 1955. He said, "existing traffic jams only faintly foreshadow those of ten years hence unless the present rate of highway improvements and development is increased. To correct these deficiencies is an obligation of Government at every level." Without roads, it would be impossible to get materials to other construction projects or supply goods nationwide, making road construction and maintenance vital for the entire economy.

On this industry page, we cover a wide range of road construction topics: the industry, how roads are built, employment and occupations, work activities, road construction equipment, associations and organizations, and safety hazards. You may opt to continue reading to learn more about road construction and the road worker’s daily work activities, or you can click the hazard warning icon below and be taken directly to the safety section for this industry, its suggested PPE, and a list of potential hazards.

Click to jump directly to the Safety, Hazards and PPE section.

The oldest constructed paved streets date back to 4,000 B.C. in Ur and Babylon's Mesopotamian cities, which are located in modern-day Iraq. However, the Romans perfected road construction and used that skill to unite an extensive empire. Rome built over 120,000 KM of roads across its vast territories, allowing goods, people, and armies to move freely. One of the most famous Roman roadways was the Via Appia, shown above, stretching 120 Roman miles from Rome through southern Italy. It would be equivalent to one of our modern interstates.

Modern U.S. Interstate Highway

In 1956, President Eisenhower created the modern U.S. version of Via Appia when he signed into law the Federal-Aid Highway Act. From his experience in World War II, where he was tasked with moving soldiers across Germany's four-lane highways, Eisenhower knew the vital importance of road systems. He is quoted as saying some four years before the legislation was passed, “The obsolescence of the nation’s highways presents an appalling problem of waste, danger, and death.”

With the new interstate highway system, goods traveled faster, and isolated areas became more connected. Today there are millions of miles of roads across the U.S. infrastructure. Here is a quick look:

Road System Miles and Bridges

Urban Roads - 744,644 miles and 153,407 bridges

Rural Roads - 3,122,282 miles and 447,989 bridges

As you can tell, we've come a long way since 1956 with the miles of roads

linking cities, businesses, and communities to one another. You might wonder, how were the Roman roads

different from modern roads in their construction? While today’s asphalt roads are much smoother

than the materials such as cobblestones used thousands of years ago, cobblestones last a long time,

which is evident in ancient streets still being intact today. Asphalt has a much shorter life expectancy

and must be maintained and replaced regularly.

Yet, even though there may be some notable differences, modern roads serve the same purpose as their

older cobblestone counterparts. They both move people and goods across a vast landscape and connect

communities hundreds and thousands of miles apart.

Highway, street, and bridge construction make up the construction sub-industry identified by NAICS 237300. This coded number allows the Government to classify all businesses' activities within the sector, helping workers and suppDespite these financial downfalls and the decline in sizeliers better understand the industry. This sub-industry includes companies involved in the following construction areas:

According to IBISWorld, the highway, street, and bridge construction industry produce over $115.6 billion in economic activity each year, with over 216,000 total businesses calling this industry home. Overall, it is the 5th largest construction sub-industry and 90th largest industry overall in the U.S. However, the industry has been somewhat on a decline, reducing in size by .6% from 2015 to 2020.

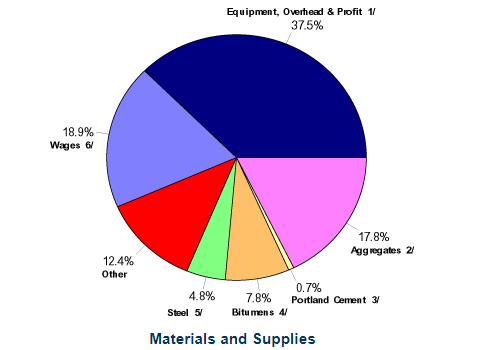

A graph showing the distribution of costs for buildingthe national highway system.

Despite these financial downfalls and the decline in size, there are some signs of optimism for the industry. The American Road & Transportation Builders Association (ARTBA) reports that 231,000 bridges across the nation need significant repair work. This means more than a third of all bridges in the U.S. need attention by construction workers in this industry. Many companies will be called on in the coming years to answer this increased need, especially as the nation’s infrastructure becomes a higher priority for the government and lawmakers. With the population on the rise, new roads will be required, and additional maintenance will be necessary to handle increased transportation needs.

How are roads constructed? Thanks to the Michigan Department of Transportation (MDOT), we have an entire outline of the process. After the initial planning phase, which is where an assessment is performed on immediate roadway needs, four more steps are needed to build a road. Here is a look at the stages of road construction:

Step 2- Earthwork:Once a roadway has been designed, construction can begin. It starts with creating a stable foundation that is formed by a grader and bulldozer. Dirt work is labor-intensive, as this is when drains and sewers are built. Lastly, gravel is positioned on the road, and additional layers are added.

Step 3 - Paving:With a solid foundation from which to build, workers spread either asphalt or concrete onto the road. With asphalt, a compact hot mixture of bitumen, sand, and crushed rock is used. When using concrete, cement, and water are used to keep sand and crushed stone together to create a smooth driving surface. The engineers of the road construction project will use whatever material has been approved by the state.

Step 4 - Open:Before the new roadway is opened to the driving public, tests are carried out to assess vibrations and drainage. Depending on the results, additional pavement and landscape improvements may be required. Once the road has passed all the necessary tests, it is ready for motorists!

Once fully completed, new roads connect distant areas, like the new I-69 interstate running from Michigan to Texas and designed to connect Canada and Mexico. I-69 is planned to be completed by 2024. older roads, regular maintenance, and road repairs ensure that drivers will have a smooth ride instead of potholes and bumps. To keep old and new roads running smoothly, though, requires workers and lots of equipment.

The U.S. Department of Transportation is the federal agency concerned with transportation and infrastructure, including roads and bridges. Here are all the administrations that are housed under this department:

![]()

FHWA is an essential component in the development of roads. However, numerous other associations assist construction workers. Here are some other professional groups guiding those who operate in the road construction industry.

The Associated General Contractors of America (AGC) – This trade association represents over 27,000 members across the construction industry and is the largest construction association.

AmericanRoad and Transportation Builders Association (ARTBA) – All aspects of transportation construction are brought together with ARTBA initiatives.

NationalAsphalt Pavement Association (NAPA) – This group represents all those producing asphalt or contracting out asphalt work.

All road construction associations have one thing in common: keeping road construction workers armed with the most relevant, up-to-date information possible to help them best perform their job. Many employees in this industry look to these associations for answers.

According to the Bureau of Labor Statistics (BLS), over 351,000 people are employed in Highway, Street, and Bridge Construction. Many artisans are operating in this industry, as it takes various skills to produce a new road. Here are some of the primary occupations working in the industry:

Highway Maintenance Workers

Maintain highways, roads, and airstrips.

Paving, Surface, and Tamping Operators

Use equipment to apply asphalt and material to roads.

Cement Masons and Concrete Finishers

Shape rock and stone into shapes needed to construct bridges.

Carpenters

Build retaining walls on roads and create forms to build bridges.

Heavy Equipment Mechanics

Work on, maintain, and fix broken heavy machinery.

Structural Iron and Steel Workers

Assemble steel frameworks and structural support on bridges.

These workers may all specialize in different areas. However, they share more similarities than one might think. According to O*NET OnLine, they all spend time enduring outdoor weather, and 94% of highway workers surveyed agreed with that fact. Highway, street, and bridge construction workers are also exposed to various contaminants on the job. Let's dive into the activities, tools, and equipment these workers use, as they play an essential role in worker safety.

Building and maintaining roads involves numerous workplace activities carried out by workers with a variety of skills. Below are some of the various activities performed by highway maintenance workers and paving operators:

All the activities we've highlighted above pertain to highway and road workers. However, masons and carpenters are also highly influential in road construction. You will find activities performed by masons on our Masonry industry page, and many carpenters’ daily activities are located on the Carpentry industry page.

Every construction sub-industry requires a unique set of tools to carry out construction and maintenance work. Transportation infrastructure requires heavy construction, which means an even greater range of materials and tools are needed.

We highlight these because many injuries workers suffer are caused by the tools they use.

No matter where they work or what task they perform, road construction workers are regularly exposed to various on-the-job hazards. Workers must always perform their duties with safety in mind; otherwise, someone will be hurt. Accident and injury rates can be lowered by knowing when and where injuries are likely to occur and wearing the proper PPE to protect against the dangers.

Accidents and injuries are common across the construction industry, especially among road workers. Work zone areas close to active public roadways are always dangerous for both drivers and workers.

Source:U.S. Bureau of Labor Statistics

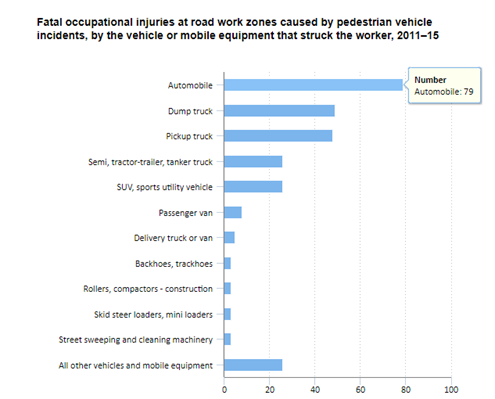

The Federal Highway Administration reported that 27,037 people lost their lives in work zone incidents from 1982 to 2017. And the BLS informs us that from 2011 to 2015, 609 workers were killed at road construction sites. So, as the numbers show us, everyone is at risk when driving through a hazardous work zone.

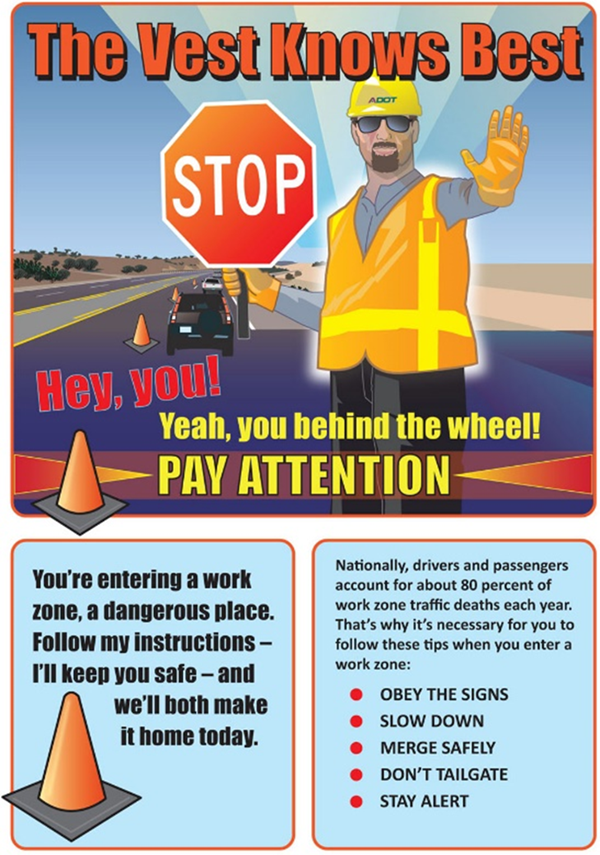

When you see orange, it's a good indicator you should

start slowing down

In 2004, new federal regulations required that anyone working next to a federal-aid highway must wear hi-vis

clothing that meets ANSI Class 2 or Class 3 safety vests' requirements. These specific vests have increased

amounts of reflective material, helping workers stand out to passing cars or those operating nearby. Also,

higher-rated vests help workers stay

seen at dusk, dawn, or

in other low-light conditions.

Here are some additional 2019 BLS stats that provide insight into areas that are concerning for road

construction workers:

And, unbelievably, workers also face injury when they are struck by cans and bottles thrown from

passing vehicles. So, once again, it's imperative workers stay focused on safety at all times.

There are numerous other hazards that we will identify below in our hazard section. Before we move on to

exploring the PPE needed to keep workers in this industry safe, here are some other helpful online resources

regarding safety topics:

With all the safety information and hazard information we've equipped you with, you're now ready to start considering PPE options available to the highway, street, and bridge workers.

Warm weather is a clear indicator that road work has started on interstates, roads, and streets. And, when

temperatures begin climbing, road workers want cool and comfortable hi-vis clothing that breathes. However,

when those temperatures start dropping, workers need hi-vis clothing that keeps them warm. How do we know

this is true?

Road work is an outdoor job, and outdoor jobs leave workers exposed to the elements. In fact, 95% of highway

workers surveyed by the Department

of Labor said they were

exposed to outdoor weather every day. In the summer, they're exposed to hot conditions, and during the

winter, they are exposed to colder conditions. Regardless of the weather, they're working in, staying seen

with hi-vis clothing is a must, which is where MCR Safety enters the picture.

Here is a broad list of various PPE MCR Safety supplies to help highway and bridge workers stay protected:

Do you know what else those workers who were surveyed said? To help stay safe and protected, 86% of them said they wear protective

clothing every day. As you can see from our list above, we have a wide variety of the kinds of PPE road

construction workers need to stay safe and unharmed while at work.

We've highlighted a lot of information and thrown a bunch of industry stats at you. This page's remaining

part showcases all the hazards and different PPE options highway and bridge workers should consider wearing

while performing their job.

If you prefer to return to the main Construction home page, click the image below. From the home page, you'll be able to access any of the numerous construction industries we cover. If you would prefer to check out some of road construction’s specific hazards, please continue reading below the Construction page image.

Find the right MCR Safety product that protects you against these common hazards.

When Old Man Winter arrives, anyone working on a construction site needs their hands and body warmed with balaclavas, insulated gloves, and garments.

Demolition operations are part of the revising process when refurbishing bridges and roads. So it makes sense to keep the back-of-hand protected when picking up and moving all the loose debris.

Learn More About Crush and Impact Protection

Every construction site requires steel toe boots, as there is always the possibility that tools, items, or material may fall onto a worker’s feet.

Exposure to toxic substances causes 12% of all injuries in this industry. Whenever a worker is spraying or exposed to chemicals, they should consider wearing chemical-resistant gloves. We've got a vast lineup!

Asphalt absorbs the sun's rays, making conditions hot for those working on the blacktop. To avoid heat-related illnesses, workers should consider wearing moisture-wicking hi-vis clothing that can go a long way in keeping the body cool.

When lifting and carrying heavy items such as equipment and materials, it helps to have some extra padding in the palm of a pair of protective work gloves.

The industry ranks 5th for thermal burns. Bitumen burns are common for workers, as it is heated to 232°C for spray applications and only slightly lower temperatures for road paving.

Flying asphalt and broken rock from jackhammers are all over in road construction. Keeping eyes protected with safety glasses is a must. A face shield is also necessary to protect one's eyes and face when cutting or grinding.

Working in the rain is no fun. Workers turn to MCR Safety’s hi-vis rainwear, bomber jackets, and raincoats to keep them dry.

Learn More About Inclement Weather Protection

Have you seen the number of materials stacked up next to a road under construction? Abrasion injuries are common across this industry as someone has to move and place all those materials in the appropriate spot. This task requires hand protection.

Anyone working close to a federally funded highway must wear Class 2 or Class 3 hi-vis clothing. Flaggers, the workers who control traffic and signaling others to drive, must wear reflective clothing, as must anyone operating near mobile construction equipment. We have an entire product line workers can choose from, including safety vests, hi-vis shirts, and hi-vis jackets.

Learn More About Overall Visibility Protection

Splinters, small metal chips, and burrs are found all over road construction sites. Sharp pointed metal can rip through low puncture-rated gloves! Workers should wear higher puncture-rated gloves to protect their hands.

Many road workers come across jagged rebar and other sharp objects on the job. Over 18% of all hand injuries are from cuts and lacerations. Construction workers come into constant contact with rough, sharp, and jagged surfaces.

Learn More About Sharp Objects Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.