The Fabricated Structural Metal sub-industry consists of companies re-fabricating metal buildings and panels. In addition, they manufacture structural metal and metal plate products. These companies are known for fabricating iron and steel for structural purposes and metal sections. Examples include bridges and buildings, ships, boats, and barges. To help visualize what this industry entails, take a look at these images:

Bridge Building, Metal Building and Ships

The Structural Metal industry employs a little over 450,000 employees. The ironworker is the occupation known for making metal structures appear before us. These workers use shear, rod-bending machines and welding equipment to cut, bend, and weld.

Iron worker reinforcing rebar. We cover more about Iron workers below.

Roughly, 25% of all Structural Metal workers are welders, cutters, and brazers, encompassing around 115,000 workers. OSHA estimates there are 562,000 total welders in the US. Think of it this way, essentially 20% of all US welders work in the Structural Metal industry. Based on these stats, Welding safety gear is essential for protecting workers from metal spatters, molten metal, UV and radiant heat.

A worker stick welding on structural metal. We breakdown this process on our Welding Protection page, along with Mig Welding, Tig Welding, Cutting and Torch Welding.

Here is a look at all occupations found across this industry. Click on an occupation to expand and learn more.

Assemble finished products, along with parts and pieces that go into them. There are over 1.8 million people employed across the US in an assembly and fabrication position. You will find this worker assembling bolts, using many different types of tools, and moving heavy parts. There are around 56,000 of these workers in Structural Metal.

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 19,000 of these workers in the Structural Metal industry. You will find these workers aligning metal parts and grinding out sharp edges. This makes cut resistant gloves a high priority for this worker. Common Job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, Press Punch Operator.

Operate machines to taper, shape and form metal. Around 3,500 workers are found in Structural Metal. You will find these workers removing dies, forging hammers and moving metalwork pieces. Common Job titles for this position are Forger, Blacksmith, Hammer Operator, and Forge Press Operators

Lubricates machines, changes parts, and performs machinery maintenance. You will find these workers cleaning machine and machine parts. Cleaning solvents, oily parts and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 1,700 of these workers in Structural Metal. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Operate machine tools to produce precision parts. There are around 6,500 machinists working in this industry. Job titles for this position Gear Machinist, Machine Operator and Maintenance Machinist.

Operate machines designed to cut, shape and form metal. Over 40% of the workforce in this industry falls into this occupation, roughly 105,000.

Keeps and repairs machines, mechanical equipment, or the structure of an establishment in repair. There are around 4,000 of these workers in the Structural Metal Industry. You will find these workers pipe fitting, repairing equipment, and repairing buildings. Job titles for this position are Maintenance Worker, Maintenance Mechanic, and Facilities Manager.

Operate cutting and forming machines. There are roughly 24,000 of these workers in Structural Metal. Common Job titles for this position are CNC Machine setter, CNC machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

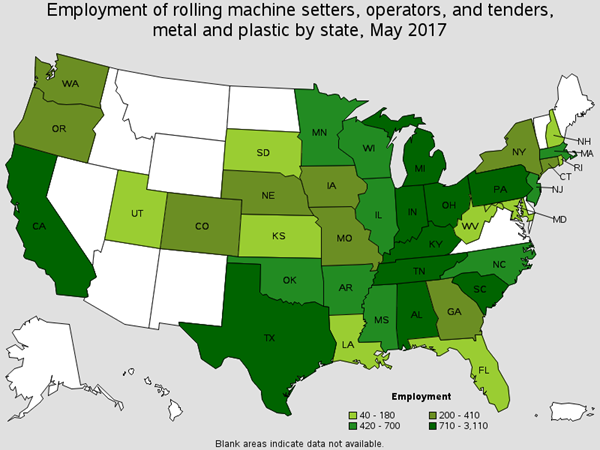

Operate machines that plate, roll and flatten steel. Around 2,200 of this occupation works in Structural Metal. You will find these workers around shears, grinders and adjusting machines. Common Job titles for this position are Rolling Mill Operator, Mill Operator and Roll Form Operator.

There are roughly 18,000 of these workers in Structural Metal. Check out our entire Industry page for more detailed information about these workers.

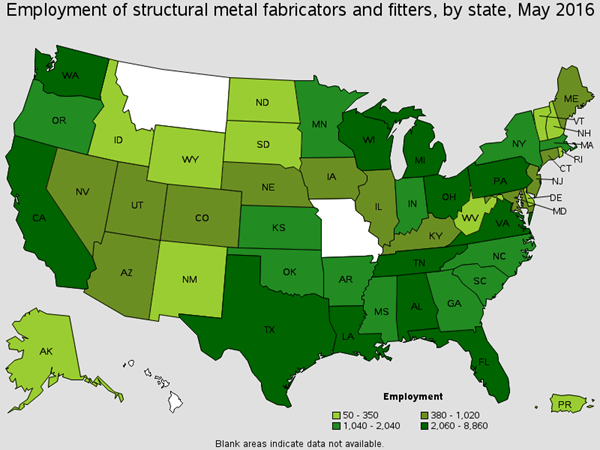

Fabricate, position, align and fit parts of structural metal products. There are a little over 25,000 of these workers in Structural Metal. You will find these workers positioning welding parts and moving parts into position. Common Job titles for this position are Fabricator, Mill Beam Fitter, Structural Steel Fitter and Layout Man.

Raise and place iron columns. There are a little over 2,000 of these workers in the Structural Metal industry. You will find these workers connecting beams and aligning bolts. Common Job titles for this position are Iron Worker, Steel Fabricator, Structural Steel Erector, and Steel Worker.

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. The Structural Metal industry employs around 58,000 employees. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 48,000 of these workers are employed in Structural Metal. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator.

Here is one more stat to consider. The Bureau of Labor Statistics (BLS) reports that 10% of all US eye injuries result from the work of welders, cutters, and brazers. Well, you don’t have to be Einstein to realize this industry is concerned with eye injuries. We’ve got these workers covered with shaded welding glasses. We cover all welding gear in our welding gear protection page.

"Safety First is Safety Always"

When Structural Metal Workers are shaping metal, they must always be ready for workplace injuries. This means they must first know the hazards faced, from welding sparks, to cuts while grinding, and UV radiation. We have got this industry's workers covered with high quality welding gear, stylish eyewear and comfortable protective garments. MCR Safety, We Protect People!

Find the right MCR Safety product that protects you against these common hazards.

Structural metal assemblers work around a lot of abrasive metal.

Common Applications

Your hand smashed between a hammer and metal is no joke!

Learn More About Crush and Impact ProtectionCommon Applications

Steel baking under the hot sun can bake your hands!

Common Applications

Your body, eyes and legs are going to need some protection. Safety gear is priceless for this type of environment!

10% of all US eye injuries result from the work of welders, cutters, and brazers. 115,000 welders in this industry need protected.

Learn More About Impaired Vision ProtectionCommon Applications

Welders rely on MCR Safety welding gear in the roughest working environments.

Common Applications

Sharp pointed metal can rip through low puncture rated gloves! You'll want to wear higher puncture rated gloves.

Learn More About Puncture Protection

Radiation from high-temperature surfaces are always a concern. Our UV rated face shields and eyewear will keep you protected.

Learn More About UV Radiation Protection

Welders are working around sharp metal. The perfect solution is welding and cut protection gloves.

Common Applications

Hot sparks are no match for MCR Safety's welding gear.

Common Applications

The saying goes, "You don't know what you don't know". Let our 360 team help you know more abut PPE.

Learn More About Lack of Safety Knowledge Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.