Machine shops play an important part in the metal fabrication industry. This is where metal parts are cut to different sizes and tailored for specific end use applications. These shops ultimately machine metal parts for industries, like the aircraft and automotive industries.

Heavy Machine Shop

Machinists use various types of equipment for cutting raw materials into specified shapes and sizes. Here is a look at some of the machines utilized:

An endless saw, typically in a vertical position.

Drilling and boring holes into metal. Drilling and cutting metal are activities where many workplace eye injuries occur.

Removing excess material from a work piece.

Rotating tool for cutting, sanding, and shaping metal.

A machine for rotating a cutter on flat metal surfaces.You will definitely need cut resistant gloves when handling the milling cutters.

Circular saw mounted on the underside of a bench.

While there are machine guards in place for protecting workers, there are still many hazards where PPE is essential. All of the above machines put a wearer’s eyes at risk. Flying debris, metal fragments, metal projectiles and particles are real concerns for those working around machines. In addition, workers cleaning these machines put their eyes and hands into direct contact with harsh splashing chemicals. When it comes to hand injuries, many injuries occur when workers are moving sharp metal across the machine shop. We cover all the machine shop hazards more in depth below. Before going into the hazards though, let us closely examine the workers that make up this industry.

In 2017, the Bureau of Labor Statistics (BLS) reported there were over 370,000 total Machinists working in the US. These workers use hand machine tools to fabricate or make modifications to metal, plastics or wood. When you look only at Machine Shops, there are a little over 84,000 machinists across the US. Here are the other workers making up this industry:

Assemble finished products, along with parts and pieces that go into them. There are over 1.8 million people employed across the US in an assembly and fabrication position. You will find this worker assembling bolts, using many different types of tools, and moving heavy parts. There are around 12,000 of these workers in Machine Shops.

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 5,700 of this occupation working in Machine Shops. You will find these workers aligning metal parts and grinding out burrs or sharp edges. This makes cut resistant gloves a high priority for this worker. Common Job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, Press Punch Operator.

Operate grinding tools that remove excess metal material or burrs. There are around 1,400 of this occupation working in Machine Shops. You will find these workers sharpening edges and corners, along with polishing metal. Common Job titles for this position are Deburrer, Finisher, Grinder, and Grinding Operator.

Inspect machined, fabricated or assembled parts. There are around 9,400 of these workers are found in Machine Shops. Common Job titles for this position are Quality Technician, Inspector, and Picker / Pacer.

Worker activities include repairing, installing, and adjusting industrial machinery. With so many machines operating, this occupation should be no surprise. There are around 2,900 of these workers in Machine Shops. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Lubricates machines, changes parts, and performs machinery maintenance. Machine Shops employ a little over 7,700 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oily parts and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Manually move materials to perform general labor. You will find this occupation loading docks and moving materials to production areas. Around 3,400 of these workers are in the Machine Shops.

Operate lathe and turning machines to turn, bore, thread and form metal. You will find these workers replacing worn tools, sharpening dull cutting tools and using cutter-grinding machines. Common Job titles for this position are Screw Machine Operator, Turn Operator, and Lathe Set Up Person.

Operate machine tools to produce precision parts. Job titles for this position are Gear Machinist, Machine Operator and Maintenance Machinist.

Machinists are the workers who utilize the machine and cutting tools. This occupation is highly skilled at operating machinery.

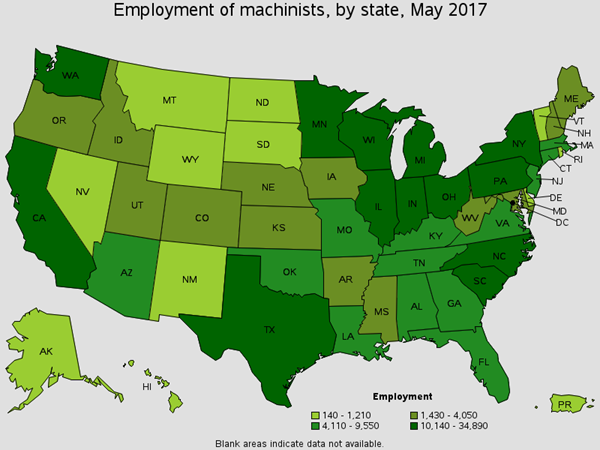

Most active States for Machinists

Operate cutting and forming machines. Roughly, 6% of the workforce falls into this occupation. There are roughly 16, 000 of these workers. Common Job titles for this position are CNC Machine setter, CNC machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

Operate computer-controlled machines or robots to perform machine functions on metal or plastic work pieces. There are around 23,000 of these workers in Machine Shops. You will find these workers removing metalwork pieces and installing metalwork pieces. Common Job titles for this position are Brake Press Operator, Machine Operator, and CNC Operator.

Around 4,000 of these workers help move steel and other material across steel factories.

Operate milling or planning machines to mil, plane, groove or profile metal. There are around 2,300 of these workers in the Machine Shops Industry. You will find these workers securing and removing and installing metal workpieces from machines. Common Job titles for this position are CNC Machine Operator, Machine Operator, Miller and Milling Operator.

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. Machine Shops employ around 16,000 employees. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 13,000 of these workers are employed in Machine Shops. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

"For safety is not a gadget but a state of mind"

We know machinists work around a lot of gadgets and machines. To stay safe in this working environment, it truly takes an ongoing awareness and state of mind where PPE is an absolute must. As discussed above, machine shop workers are responsible for transforming metal into intermediate or end products. Every time metal is transformed, there are inherent risks and hazards faced. MCR Safety is committed to the challenge of keeping metalworkers safe. Let's get your state of mind focused on the hazards Machine Shops face!

Find the right MCR Safety product that protects you against these common hazards.

Cleaning, wiping off, and degreasing machines expose workers to harsh chemicals. In addition, machine and metalworking fluids affect workers hands.

Common Applications

We’ve got featherweight and touchscreen gloves to help you operate control panels.

Keep those hands safe from cutting oils and keep your grip with Grippaz technology.

Common Applications

Machine parts and work pieces get a little hot! You will some nice heat protection when touching that hot drill bit next time.

Common Applications

Working around metal exposes you to flying fragments, particles and projectiles.

Going inside and outside is a nightmare for those needing clear vision inside, then dealing with outdoor glare while retrieving materials. Max 36 Indoor/Outdoor glasses are here!

Learn More About Indoor Outdoor Transition ProtectionCommon Applications

Transporting material onto the machine shop floor can rough up your hands. You will need gloves when unloading and transporting metal!

Learn More About Material Handling ProtectionCommon Applications

Gloves, Sleeves, Arm Guards, and Aprons are not recommended when working around moving machines and rotary parts.

Common Applications

Metalworking fluids, coolants, cutting oils and drilling oils are commonly found around machine parts.

Common Applications

Working on gears, chains and pulleys put your hands in immediate harms way. Check out our high dexterity, high cut resistance and back-of-hand protection.

Learn More About Pinch Points ProtectionCommon Applications

Metal splinters, small metal chips and burrs are found all over metal. Might be smart to wear some high rated ANSI puncture gloves.

Common Applications

Machine shop workers deal with sharp edges on work pieces, sharp metal chips, and cutting tools. ANSI A2 to A9 cut resistant gloves are your answer.

Learn More About Sharp Objects ProtectionCommon Applications

Not every user requires an ANSI Cut A5 glove. Our Featherweight cut gloves are the answer and will give you ultimate feel and sense of touch!

Learn More About Small and Sharp Metal Part Handling Protection

Radiation from high-temperature surfaces are always a concern. Our UV rated face shields and eyewear will keep you protected.

Learn More About UV Radiation Protection

Welders are working around sharp metal. The perfect solution is welding and cut protection gloves.

Hot sparks are no match for MCR Safety's welding gear.

The saying goes, "You don't know what you don't know". Let our 360 team help you know more abut PPE.

Learn More About Lack of Safety Knowledge Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.