The Iron Age began around 1200 BC, ending the Bronze Age that preceded it and paving the way to man’s mastery of metal. Individuals during this period began extracting iron ore to forge tools and weapons. The reason revolves around Iron being one of the most abundant metals found on earth.

Iron makes up 98% of earth’s core and 5% of earth’s crust. Iron today is the core component in steel, allowing us to build buildings, cars, ships, and weapons. In fact, we even eat Iron! Check out the nutrition facts of cereal to the right.

Iron transports oxygen through our body

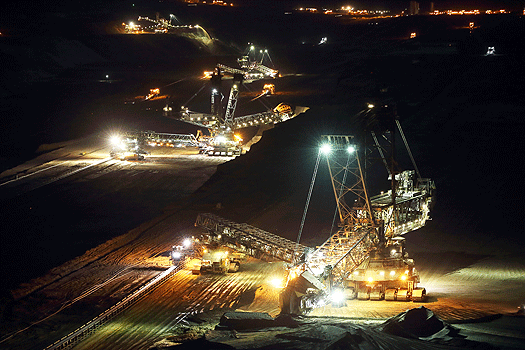

US iron mining is most prevalent in Minnesota and Michigan. The majority of the mining found for these operations is Surface Mining. This form of mining is when minerals are directly removed from the ground surface area. It is also commonly known as “open cast mining”, making up the majority of metal ore mining. More than 95% of all non-metallic minerals involved this type of mining.

Value of Minerals

Click on an occupation to expand and learn more.

Operate equipment to control chemical changes or reactions in the processing of industrial product. There are roughly around 930 of these workers found in Metal mining. You will find these workers detecting equipment leaks and drawing samples of products. Common Job titles for this position are Multiskill Operator, Production Operator, and Spray Dry Operator.

Perform tasks involving physical labor at construction sites. Mining examples include earth drillers, blasters and explosives workers, derrick operators, and mining machine operators. There are roughly around 12,000 of these workers found in Metal mining. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common Job titles for this position are Mining Technician, Helper, Laborer, Post Framer, and Construction Worker.

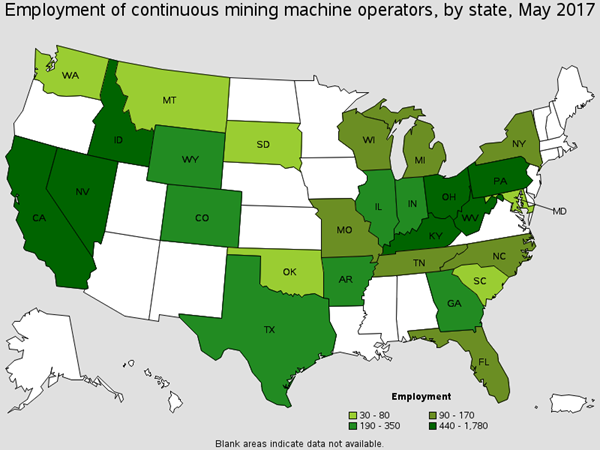

Operate mining machines that rip coal, metal and nonmetal ores, rock, stone, or sand from the mine face and load it onto conveyors or into shuttle cars. There are roughly around 3,600 of these workers found in Metal mining. You will find these workers assisting in construction activities, checking the roof stability and cleaning equipment. Common Job titles for this position are Bore Mine Operator, Miner Operator, and Continuous Miners.

Install, maintain, and repair electrical wiring, equipment, and fixtures. Around 1,100 of this occupation in Metal mining. You will find these workers connecting wires to breakers and transformers, making dielectric and FR safety gear important. Common Job titles for this position are Industrial Electrician, Journeyman Electrician and Wireman, and Maintenance Electrician.

Place and detonate explosives to demolish structures or to loosen, remove, or displace earth, rock, or other materials. May perform specialized handling, storage, and accounting procedures. Includes seismograph shooters. There are around 1,000 of these working in Mining. You will find these workers placing explosive charges in holes and shoveling drill cuttings. Common Job titles for this position are Blaster, Explosive Technician, and Powderman.

Help craft workers by supplying equipment, cleaning areas, and repair drilling equipment. Extraction craft workers are earth drillers, blasters and explosives workers, derrick operators, and mining machine operators. There are around 8,400 of these workers. Common Job titles for this position are Blasting Helper, Miner Helper, and Driller Helper.

Operate or tend heating equipment other than basic metal, plastic, or food processing equipment. There are around 1,000 of these working in Mining. You will find these workers handling, moving objects and clearing equipment jams. Common Job titles for this position are Dry Kiln Operator, Dryer Feeder, and Overn Operator.

Repair overhaul mobile mechanical, hydraulic, and pneumatic equipment. Examples of this equipment includes cranes, bulldozers, graders, and conveyors. There are around 2,100 of these workers found in Quarries. You will find these working replacing worn parts and reassembling heaving equipment with tools. Common Job titles for this position are Heavy Equipment Technician, Field Mechanic, and Mobile Heavy Equipment Mechanic.

Lubricates machines, changes parts, and performs machinery maintenance. Mining employs a little over 3,700 of these workers in Metal mining. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

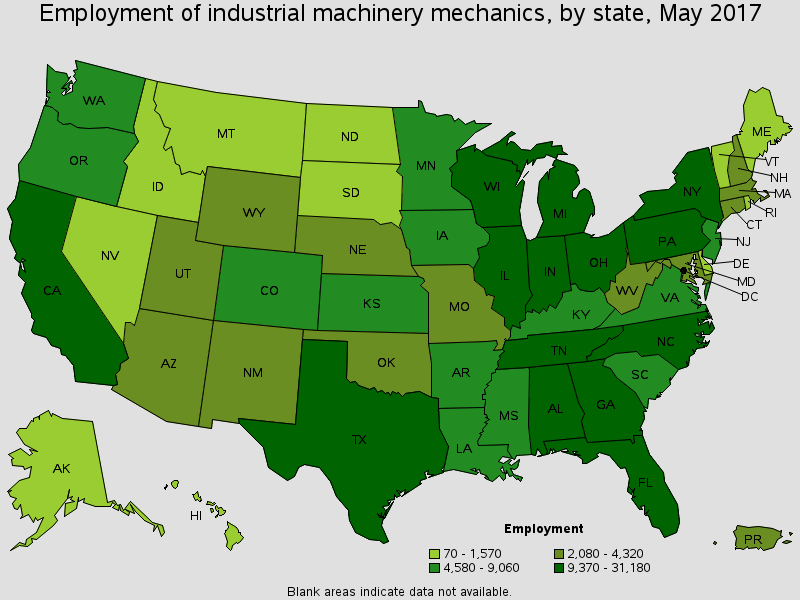

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 2,400 of this occupation working in Metal mining. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Operate machines designed to cut, shape and form metal. There are roughly 1,100 employees found for this occupation. You will find this worker fabricating metal products, lifting heavy material and working with their hands. Common job titles for this position are sheet metal worker and welder. Be sure to check out our Metal Fabrication industry educational page.

Keep machines, mechanical equipment, or the structure of an establishment in repair. There are around 3,000 of this occupation found in Metal mining. You will find these workers pipe fitting, repairing equipment, and repairing buildings. Job titles for this position are Maintenance Worker, Maintenance Mechanic, and Facilities Manager.

Repair, or overhaul mobile equipment, such as cranes, bulldozers, graders, and conveyors, used in construction, logging, and surface mining. There are roughly around 2,100 of these workers found in Metal mining. You will find these workers replacing worn parts and reassembling equipment using hand tools. Common Job titles for this position are Heavy Equipment Technician, Field Mechanic, and Equipment Mechanic.

Operate continuous flow / vat-type equipment; filter presses; shaker screens; centrifuges; scrubbing towers; and batch stills. There are roughly around 930 of these workers found in Metal mining. You will find these workers pouring unrefined material into machines. Common Job titles for this position are Machine Tender and Plant Operator

Help operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. The mining industry employs around 500 of these workers in Metal mining. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 500 of these workers employed in Metal mining. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator.

“As Iron sharpens Iron, so one man sharpens another”

Let us help sharpen your PPE knowledge and keep you protected from the many mining hazards faced. Before we cover our product solutions, here are the most common overall hazards miners face.

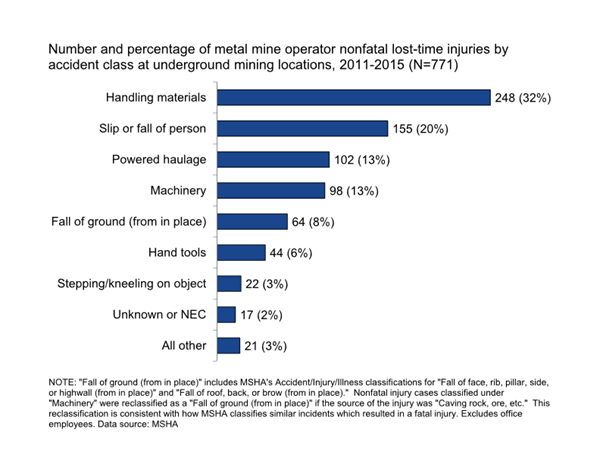

Metal mine operator injuries

Metal mine operator injuries

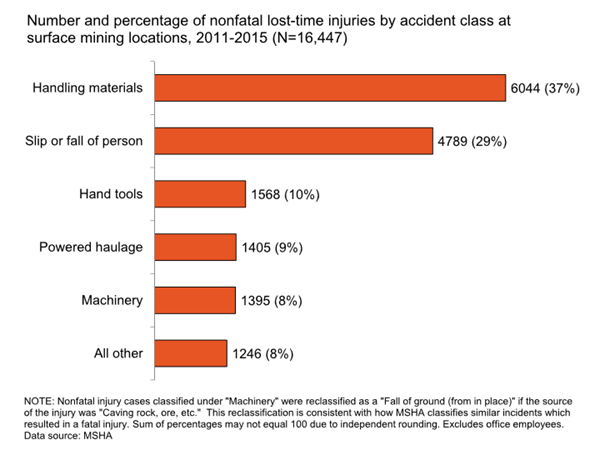

Nonfatal Surface mining injuries

Nonfatal Surface mining injuries

Find the right MCR Safety product that protects you against these common hazards.

Numerous mining injuries occur from working around low roofs, confined spaces, shoveling, lifting, and climbing. We have highly abrasive gloves for this very reason.

Impact in confined spaces, impact from crush and other mining equipment, heavy tool handling, falling rocks, tire changing, using grinding equipment and loading materials can all be hard on the back of a worker’s hands.

Learn More About Crush and Impact Protection

Mining underground and tearing into the earth is just a little dirty at times. Mining coveralls for underground mines and raingear for outdoor surface mining are absolute necessities.

Learn More About Dirt, Grime, and Fluids Protection

Dirt and dust are virtually in all mining environments. Drilling, blasting, and dust generated from hauling trucks are create a ton of dust. It is known as one of the top on-the-job health risks of mining.

Learn More About Dust Protection

Mines require a lot of electricity, electrical wires and electrical panels. ARC Flash protection is the solution.

Learn More About Electrical Maintenance Protection

Mine sites use a lot of heavy trucks, hydraulics, conveyors, bulldozers and equipment. Mechanics need excellent abrasive grip and many times require back-of-hand protection.

Reinforced leather gloves are essential gear for miners.

Learn More About Handling Wire and Cables Protection

Breaking up rock, drilling, and mining the earth creates flying particles. Grinding residues are present too. Check out eyewear designed for this exact scenario.

Learn More About Impaired Vision Protection

Lifting moderately heavy objects can quickly scrape up your hands. Material handling injuries are one of the leading causes of injuries for miners.

Learn More About Material Handling Protection

Many workers drive equipment in mining operations. Many mining fatalities occur due to Haul-Truck accidents. Drivers should not even second-guess wearing premier leather driver gloves.

Learn More About Operator Grip Protection

Surface mines involve many moving vehicles. High-visibility jackets, vests and reflective coveralls are a must!

Learn More About Overall-Visibility Protection

Mining requires a lot of mapping and planning. Make sure you’re seen and have plenty of pockets!

Learn More About Surveying Protection

Installing steel borehole casings down a borehole requires welding at the joints. Face Shields and welding gear is essential mining gear.

Learn More About Welding Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.