"Formula for success; rise early, work hard and strike oil."

Working hard and striking for oil is what over 500,000 workers do every day in the Oil and Gas industry. Unfortunately, though, working hard often times means dangerous work. Hands often take a beating on an Oil Rig, from banged up knuckles to hazardous chemicals. With there being no shortages of hazards faced, workers rely on high-performance PPE. MCR Safety ensures Oil and Gas workers arrive home all in one piece with its industry leading gloves, glasses and garments.

The Oil and Gas industry is broken up into four core segments:

We cover each one of these industries in depth on separate sub-industry pages. Here is a quick snapshot of each one.

Occupations working across the above oil segments are indebted to ancient earth. In fact, when enjoying modern day amenities, everyone should appreciate mother earth. From driving gas-filled vehicles to drinking water out of plastic bottles, oil and oil-based products are everywhere…

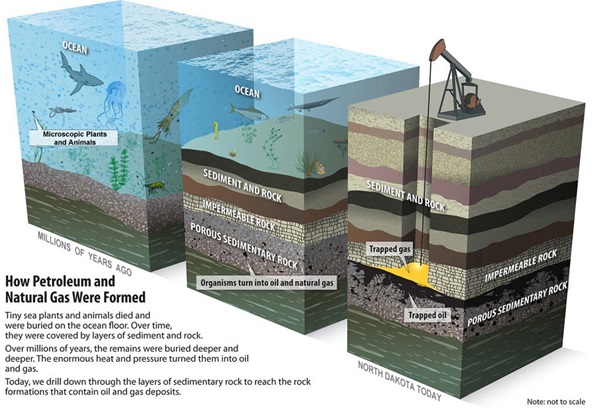

Plants and animals that lived millions of years ago are at the root source of modern day oil. After being buried on the ocean floor for many years, animal remains became buried deeper and deeper. Over time, the enormous heat and pressure turned these remains into what we know as Oil and Gas.

Today, Oil and Gas companies drill through layers of sediment and sand to extract this coveted resource.

EIA image of conventional oil and gas resources

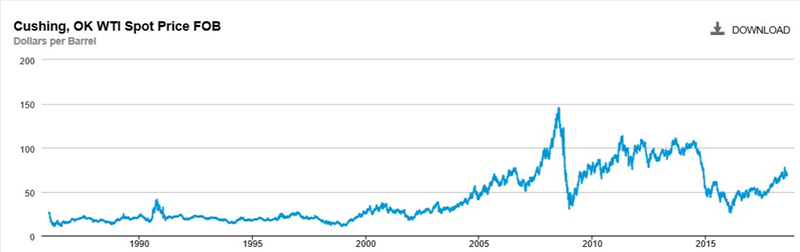

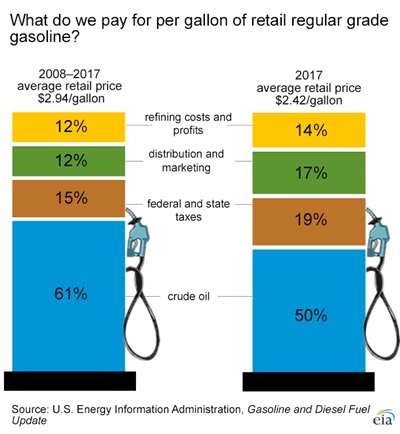

An oil hungry world significantly influences the economy and overall demand for oil extraction. When the economy is vibrant across industrial, commercial, and consumer markets, there is a great need for oil and gas resources. However, when the economy is less strong, demand for oil and gas significantly drops. Keep in mind though, decreased demand from the US economy does not always equate to a reduction in oil prices.

West Texas Intermediate Crude Oil has been on a roller coast ride over the past decade.

A global perspective is required when thinking of the oil industry, definitely, when it comes to costs and pricing. An economic event in one part of the world easily affects prices for everyone. For example, the 2011 Tsunami in Japan caused international supply distributions of natural gas. Since Japan has limited gas production, natural gas was heavily imported to create energy, causing pricing to be somewhat volatile.

The sub-industry employing the most workers is Oil and Gas extraction, which we fully cover in our Exploration, Drilling and Production industry page. Here is a look at employment across all Oil and Gas sub-industries:

| Sub-Industry | Employment |

|---|---|

| Oil and Gas Extraction | 135,480 |

| Petroleum Refineries | 112,870 |

| Pipeline Transportation | 49,000 |

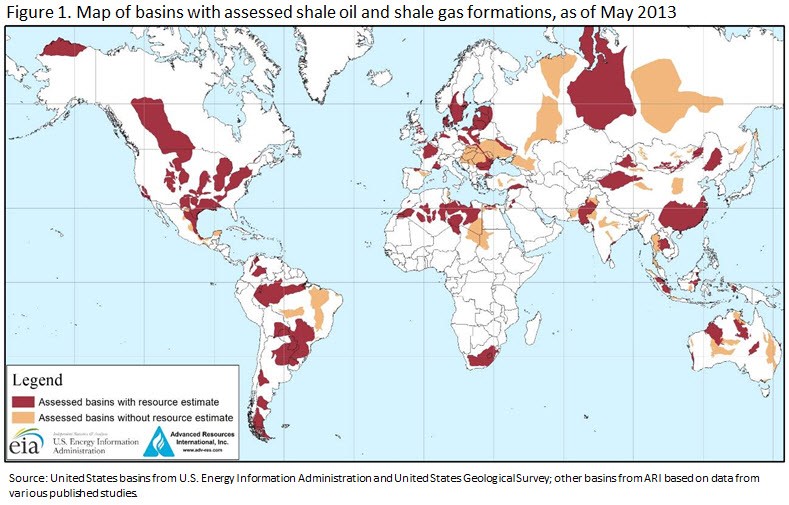

Worldwide Oil and Shale Gas formations

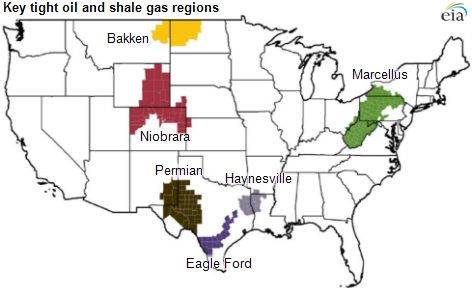

US key oil and gas regions, where many workers can be found

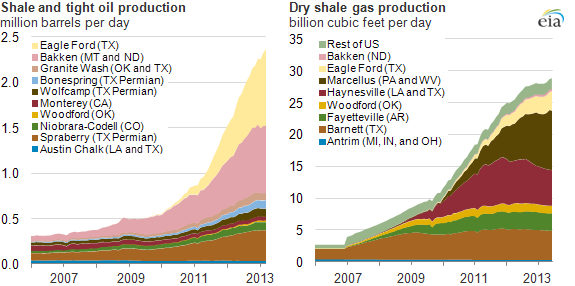

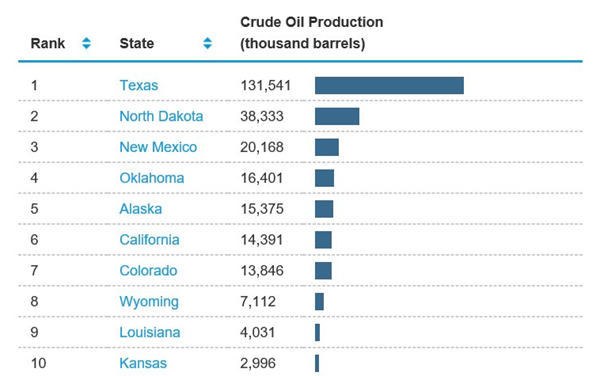

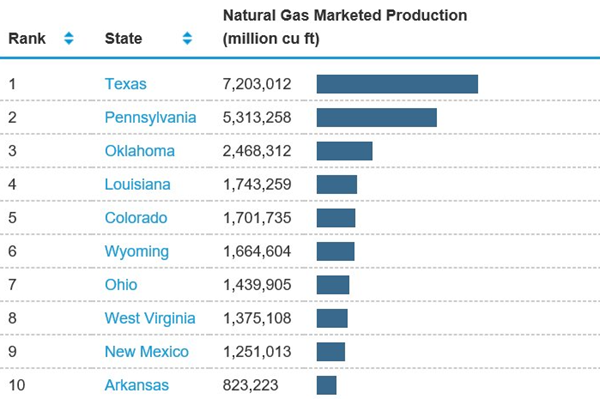

Oil production across key regions

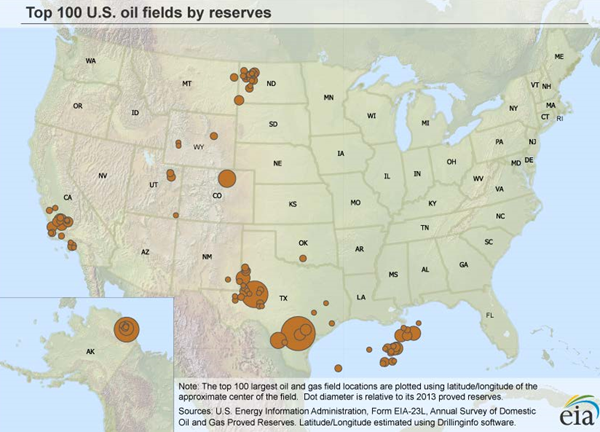

Top US Oil Reserves

Top 10 states for Oil and Gas Production

Here is a look at the occupations found in this industry. (Click an occupation to expand and learn more)

Assemble finished products and parts. There are around 1,300 of these workers in the Oil Refining industry. You will find this worker assembling bolts, using many different types of tools, and moving heavy parts. They construct finished products and the parts that go into them. These workers use alot of tools, machines, and most importanly need their hands protected. Common job titles for this occupation are Assembler and Fabricator.

Operate equipment to control chemical changes or reactions in the processing of industrial products. There are around 2,000 of these workers in the Oil Refining industry. You will find this worker adding treating agents to products, cleaning production equipment and draining pump water. Common job titles are Operator and Technicians.

Operate entire chemical processes or system of machines. Around of 1,400 of these workers are in the Oil Refining industry. You will find these workers operating chemical processing equipment, collecting samples and testing chemicals. Common job titles for this position are Chemical Operator, Process Operator, and Vessel Operator.

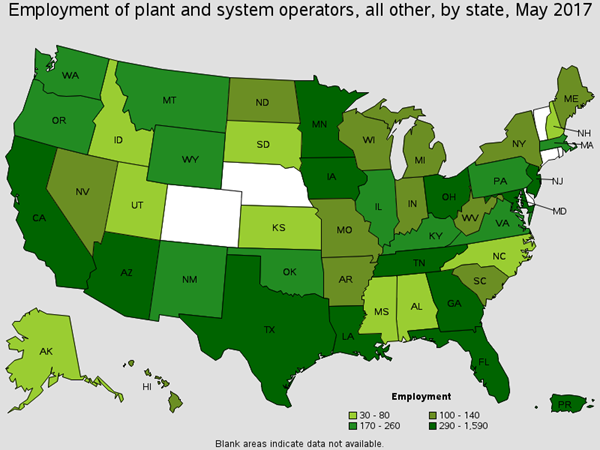

Employment of Chemical Plant and System Operators

Conduct qualitative and quantitative chemical analyses or experiments in laboratories for quality and process control. There are around 1,000 of these workers in the Oil Refining industry. You will find these workers analyzing chemical compounds, conducting quality control tests and maintaining technical equipment. Common job titles for this position are Scientist and QC Chemist.

Perform tasks involving physical labor at construction sites. There are roughly around 21,000 of these workers found in Oil and Gas extraction. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Helper, Laborer, Post Framer, and Construction Worker.

Perform tasks involving physical labor at construction sites. There are roughly around 30,000 of these workers found in the Oil and Gas industry. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common job titles for this occupation are helper, Laborer, Post Framer, and Construction Worker.

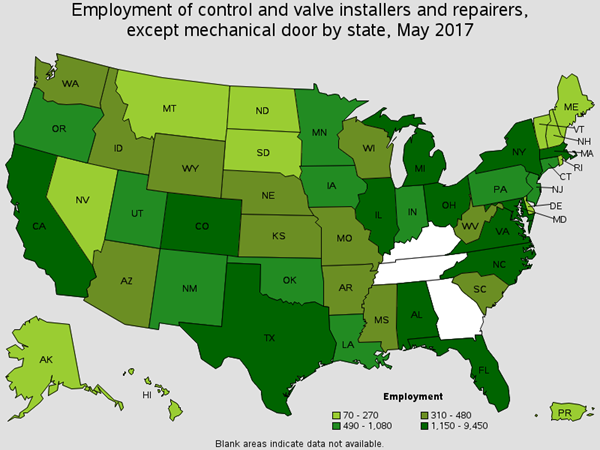

Install, repair, and maintain mechanical regulating and controlling devices and other mechanical governors. There are a little over 500 of these workers in Exploration, Drilling and Production. You will find these workers repairing mechanical control devices, lubricating mechanical parts, and installing electric meters. Common job titles for this worker are Control Valve Technician, Service Technician, and Valve Technician.

Employment of Control and Valve Installers and Repairers

Operate machines to crush, grind, and polish materials. There are roughly around 4,800 of these workers found in the Oil Refining industry. You will find these workers mixing chemicals, collecting materials and using picks. Common Job titles for this position are Batch Mixer, Fabricator, and Miller.

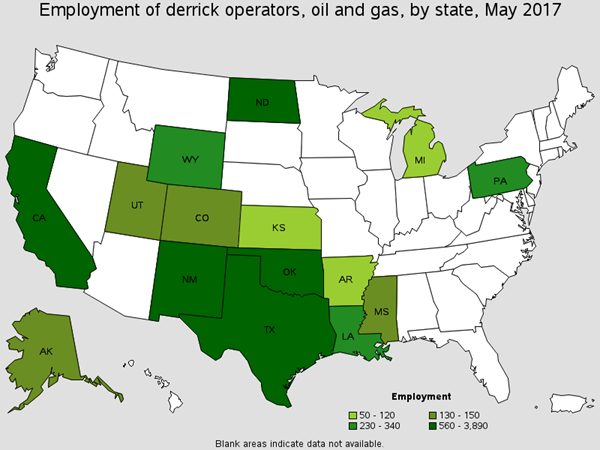

Rig derrick equipment and operate pumps to circulate mud through drill holes. There are around 9,200 of this occupation employed in Exploration, Drilling and Production. You will find these workers inspecting derricks, repairing mud tanks, and setting crown blocks to posts at the top of derricks. Common job titles for this occupation are Derrick Hand, Derrick Worker and Floor Hand.

Employment of Derrick, Rotary Drill, and Service Unit Operators

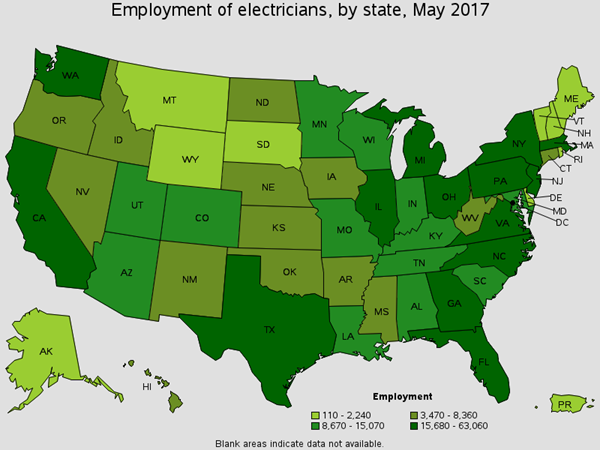

Install, maintain, and repair electrical wiring, equipment and fixtures. There are around 1,400 of these workers in the Oil Refining industry. You will find these workers connecting wires to breakers and transformers, making dielectric and FR safety gear important. Common Job titles for this position are Industrial Electrician, Journeyman Electrician and Wireman, and Maintenance Electrician.

Employment of Electricians

Operate or tend heating equipment other than basic metal or plastic processing equipment. There are around 500 of these workers in the Oil Refining industry. You will find these workers handling, moving objects and clearing equipment jams. Common Job titles for this position are Dry Kiln Operator, Dryer Feeder, and Overn Operator.

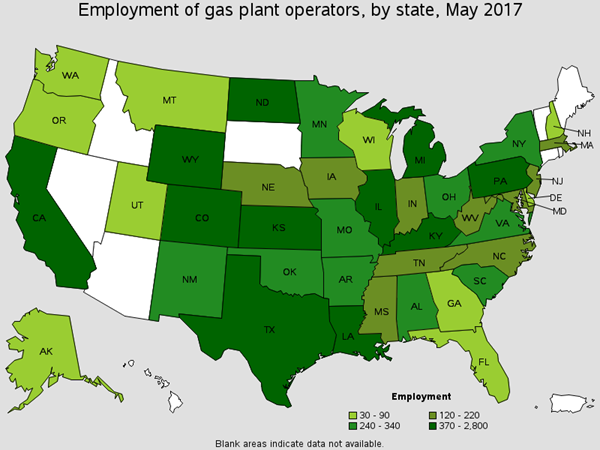

Distribute or process gas by controlling compressors to maintain specified pressures on main pipelines. There are over 6,000 of these workers in Exploration, Drilling and Production and Pipeline Transportation. You will find this worker operating plant equipment, monitoring flammable products, and controlling compressors. Job titlees for this worker are Gas Controller and Plant Operator.

Employment of Gas Plant Operators

Gather samples such as rock, mud and soil. There are around 2,800 of these workers in Oil and Gas extraction. You will find these workers monitoring well exploration activities and analyzing drill cuttings. Common job titles are Data Technician and Technician.

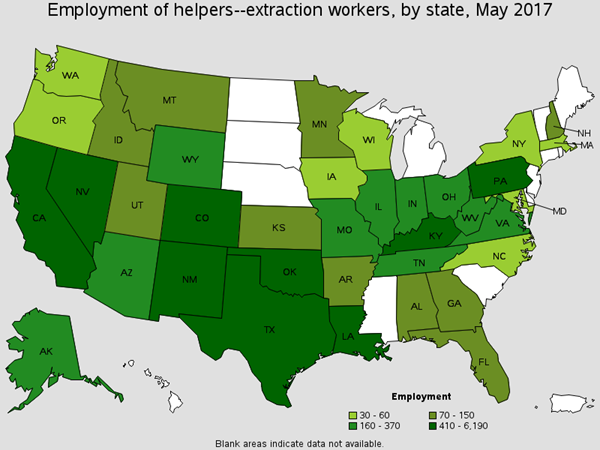

Help extraction craft worker, such as derrick operators. There are around 1,200 of these workers in Oil and Gas extraction. You will find this worker unloading materials and machine parts, operating equipment and organizing materials. Common job titles for this position are Driller's assistant and Driller Helper.

Employment of Helpers--Extraction Workers

Lubricates machines, changes parts, and performs machinery maintenance. The Exploration, Drilling and Production industry employs a little over 19,000 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

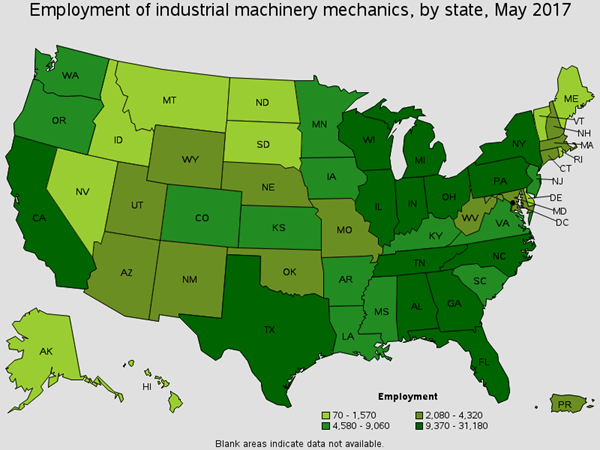

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 9,800 of this occupation works in the Oil and Gas industry. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Employment of Industrial Machinery Mechanics

Inspect machined, fabricated or assembled parts. There are around 2,200 of these workers in the Oil and Gas industry. You will find these workers inspecting equipment and structures. Common Job titles for this position are Quality Technician, Inspector, and Picker / Pacer.

Machinists are the workers who utilize the machine and cutting tools. This occupation is highly skilled at operating machinery. There are around 1,200 of this occupation working in the Oil Refining industry. You will find this worker operating machine tools to produce precision parts. Job titles for this position Gear Machinist, Machine Operator and Maintenance Machinist.

Help move materials across operations. There are around 12,000 of these workers in the Oil and Gas industry. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

Operate machines designed to cut, shape and form metal. There are roughly 2,800 of these workers in Oil Refining operations. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Common job titles are Sheet Metal worker and Welder. Be sure to check out our Metal Fabrication industry educational page.

Operate machines to mix or blend materials. There are around 4,600 of these workers in OIl Refining operations. You will find these workers mixing substances to create chemical solutions, measuring ingredients and moving objects. Common job titles are Blender, Machiner Operator, and Mixer.

This occupation makes many of the PPE related decisions within a mine. They review, evaluate, and analyze work environments. This occupation also design programs and procedures to control, eliminate, and prevent disease or injury caused by chemical, physical, and biological agents or ergonomic factors. There are roughly around 1,000 of these workers found in Oil and Gas extraction. You will find these workers recommending safety measures and evaluating workplace safety equipment. Common Job titles for this position are Certified Industrial Hygienist; Chief Safety Officer; Corporate Safety Director; Director Employee Safety and Health; Environmental Health and Safety Manager; Environmental, Health, and Safety EHS Officer; Health and Safety Manager; Risk Control Consultant; Safety Consultant; Safety Specialist

Collect data on work environments for analysis . Implement programs designed to limit chemical, physical, biological, and ergonomic risks to workers. There are 880 of these workers in Oil Refining. You will find these workers testing workplaces for chemical hazards, maintaining personal protective equipment and monitoring use of safety equipment. Common job titles for this position are Safety Professional, Safety Specialist, and Safety EHS leader.

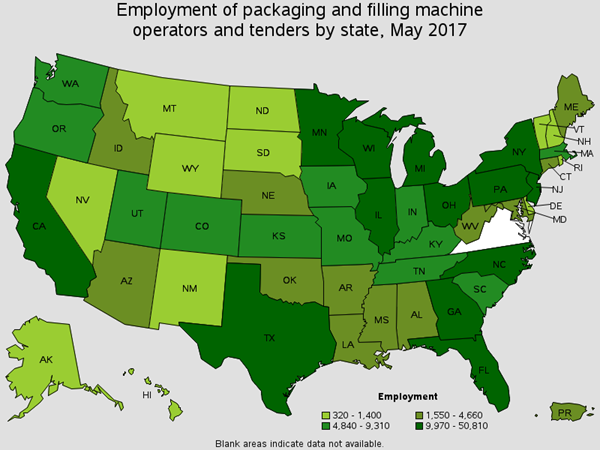

Operate machines preparing products for storage or shipment. There are around 1,400 of this occupation working in the Oil Refining Industry. You will find these workers inspecting products and removing packaged items. Job titles for this position are Machine Operator, Packaging Operator, and Fabrication Technician.

Employment of Packaging and Filling Machine Operators and Tenders

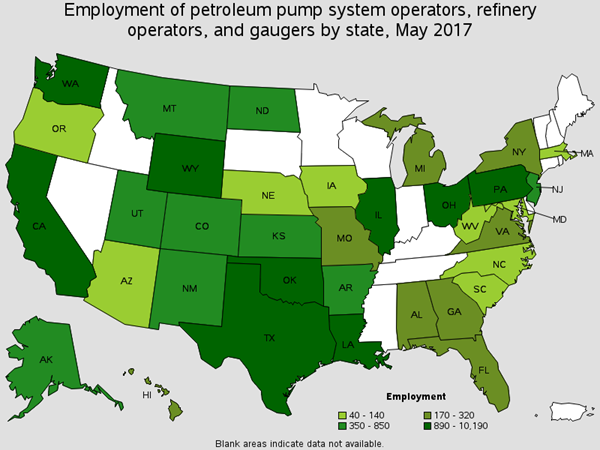

Operate petroleum refining or processing units. There are around 20,000 of these workers in Oil and Gas. You will find these workers monitoring gauges, opening valves to regualte the flow of oil, and operating manifold/pumping systems. Common Job titles for this position are Gauger, Head Operator, Pumper, and Refinery Operator

Operate equipment used for applying concrete, asphalt, or equipment used for tamping gravel, dirt, and other materials. There are around 1,100 of these workers in the Oil Refining industry. You will find these workers operating machines, cleaning machines, and spreading concrete or other aggregate mixtures. Common job titles are Operator, Paver Operator, and Roller Operator.

Operate petroleum refining or processing units. There are around 26,000 of these workers in theExploration, Drilling and Production industry. You will find these workers monitoring gauges, opening valves to regualte the flow of oil, and operating manifold/pumping systems. Common Job titles for this position are Gauger, Head Operator, Pumper, and Refinery Operator

Employment of Petroleum Pump System Operators, Refinery Operators, and Gaugers

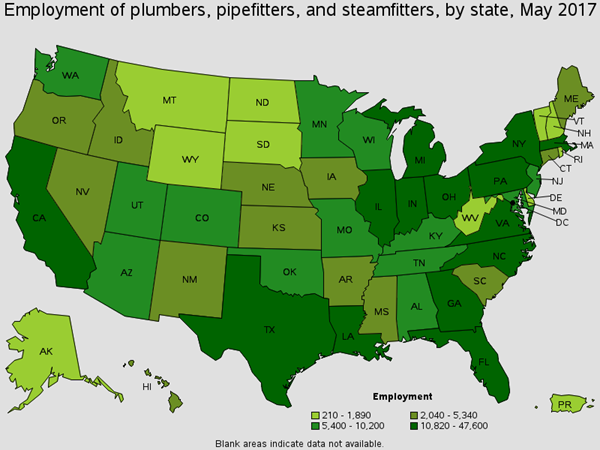

Assemble, install, alter, and repair pipelines. There around 2,100 of these workers in Refineries and Pipeline Transportation You will find these workers hammering pipes, securing pipes, and cutting piples. Common job titles for this position are Pipe Fitter, Pipe Welder, and Steamfitter.

Employment of Pipelayers, Plumbers, Pipefitters, and Steamfitters

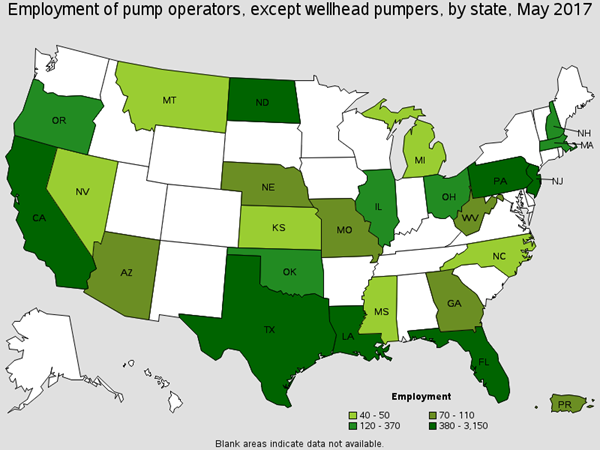

Operate power-driven, stationary, or portable pumps to transfer gases, oil, other liquids, slurries, or powdered materials to and from various vessels. There are around 900 of these workers in Oil and Gas extraction. You will find these workers tending vessels that store gasses and turning valves. Common job titles for this position are Chemical Operator, Pipeline Operator, and Pumper.

Employment of Pump Operators, Except Wellhead Pumpers

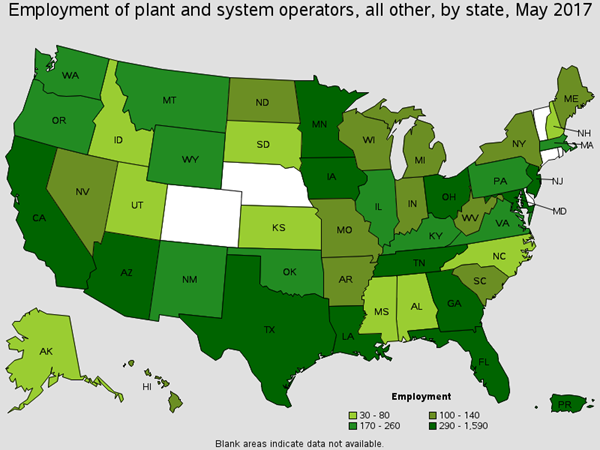

Monitor both input and output to ensure systems are working correctly. There are roughly 5,300 of these workers in Exploration, Drilling and Production. You will find these workers operating valves, engines, generators and pumps to keep everything running smoothly. Common job titles are Process Operator and Operator.

Employment of Plant and System Operators

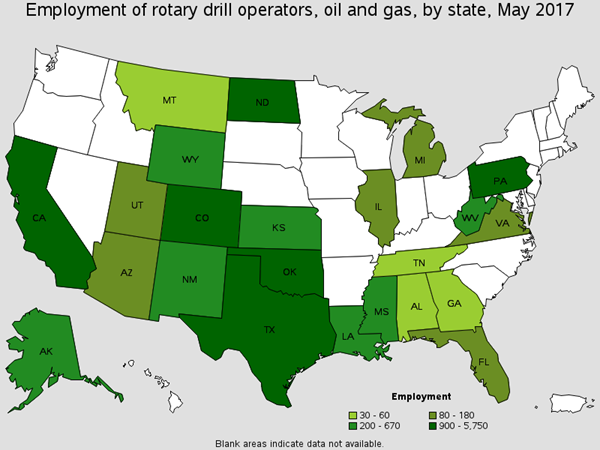

Operate a variety of drills to remove underground oil and gas. They also remove core samples for testing during oil and gas exploration. There are around 1,800 of these workers in Exploration, Drilling and Production. You will find this worker connecting sections of dril pipe, operating drilling equipment, and raising drill pipes. Common job titles for this occupation are Drill Operator, Driller, and Oil Rig Operator

Employment of Rotary Drill Operators, Oil and Gas

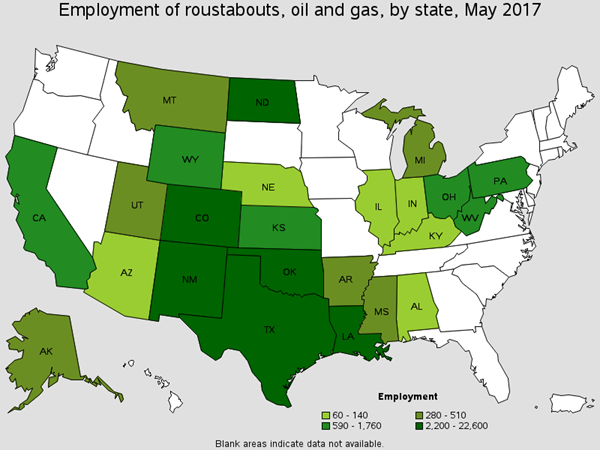

Assemble and repair oil field equipment using hand and power tools. There are around 5,000 of these workers in Exploration, Drilling and Production. You will find these workers tightening pipes, casings and pump rods. The workers move a lot of peipe and bolt together a lot of pumps. Common job titles for this occupation are Floor Hand, Galley Hand and Rig Hand.

Employment of Roustabouts

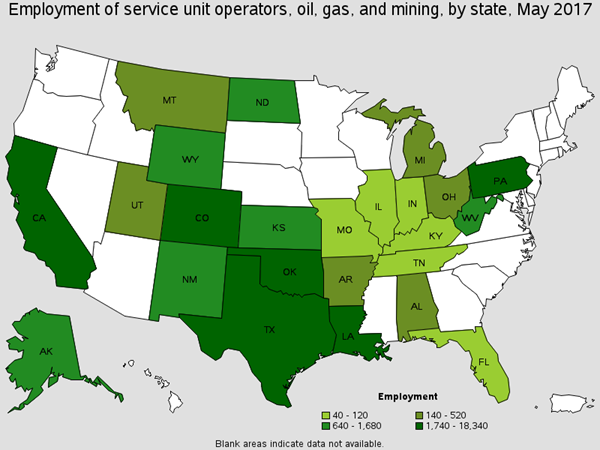

Operate equipment to increase oil flow from producing wells. There are 6,400 of these workers in Exploration, Drilling and Production. They also remove stuck pipe, casing, tools, or other obstructions from drilling wells. You will find these workers installing pressure-control devices, maintaining safety inspections and operating cranes and other lifting equipment. Common job titles are Rig Operator, Tool Pusher, and Wireline Operator.

Employment of Service Unit Operators

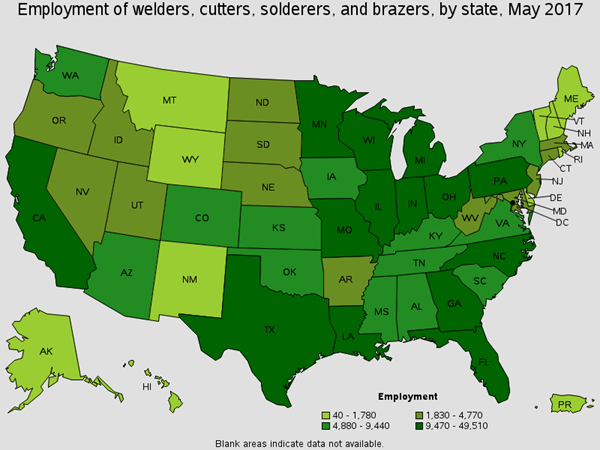

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 1,700 of these workers are employed in the Oil and Gas industry. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

Employment of Welders, Cutters, Solderers, and Brazers

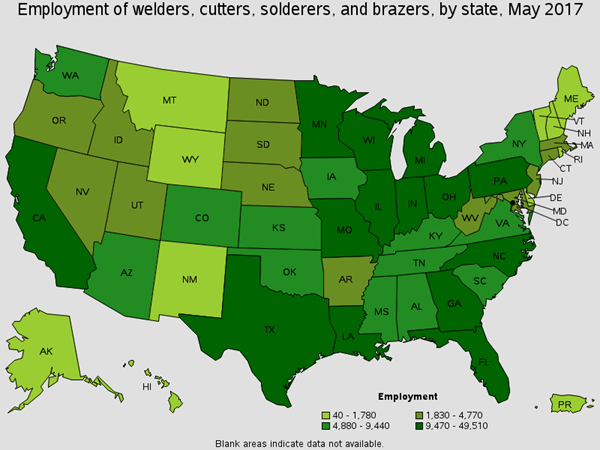

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. The Oil and Gas industry employs around 1,100 of these workers. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Employment of Welding, Soldering, and Brazing Workers

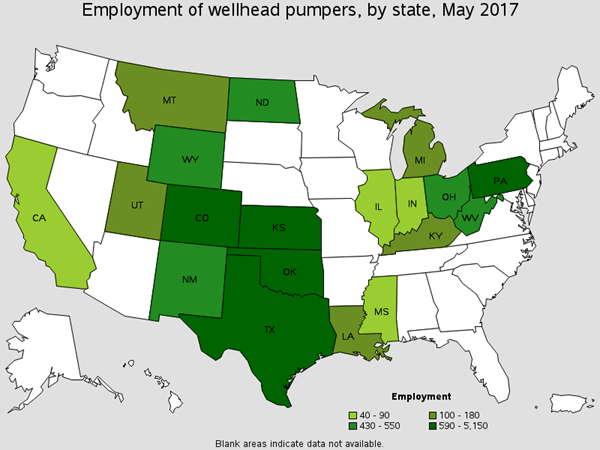

Operate power pumps producing flow of oil or gas from wells. There are around 8,000 of these workers in Exploration, Drilling and Production. You will find these workers operating pumps, unloading pipes and pumping equipment, repairing oil gauges, and performing routine maintenance. Common job titles for this occupation are Oilfield Operator, Pumper, and Well Head Pumper.

Employment of Wellhead Pumpers

Here is a look at the many work activities performed by the above occupations. We cover the hazards these activities present and the PPE needed across our sub-industry pages.

The Oil and Gas industry involves extremely hazardous work! Drilling equipment, handling heavy pipes and handling oil-based mud are just some of the many hazards above occupations face where PPE is required. Thankfully, Oil and Gas companies take safety seriously, which is evident in the below numbers.

| Oil and Gas Sub-Industries | NAICS | # of Injuries |

|---|---|---|

| Support Activies for Oil and Gas Operations | 213112 | 3 |

| Oil and Gas Extraction | 21111 | 1.5 |

| Oil and Gas Pipeline and Related Structures Construction | 23712 | 1.2 |

| Drilling Oil and Gas Wells | 213111 | 0.7 |

| Petroleum Refineries | 32411 | 0.5 |

Compared to other industries, incidents per 100 people is rather low.

"The safety of the people shall be the highest law."

The safety of people is paramount for those working across the Oil and Gas industry.

At MCR Safety, We Protect People! For over 45 yers, we've manufactured and produced PPE OIl and Gas workers have come to rely on.

Let us help keep you safe when extracting "Black Gold"!

Below is a great selection of online guides focusing on Oil & Gas protective equipment (PPE).

Learn more about MCR Safety product features that protect against these common hazards.

Click "Learn More" to find info on protecting yourself against these hazards and find the right gear for the job.

Working in the rain and around liquids is common, along with staying FR compliant. Big Jake rainwear protects workers from ARC flash hazards!

Nitrile coated products are excellent for gripping around lubricants, muds and oil. However, our new Max Grid pattern takes first prize though when it comes to gripping in oil!

Working outside involves facing Mother Nature head on, meaning wet conditions are always a concern. HPT coated gloves repel liquids, providing a firm wet or dry grip!

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.