Andrew Carnegie, the 19th industrialist who transformed the steel industry and helped build America, once said -

"The only irreplaceable capital an organization possesses is the knowledge and ability of its people."

Carnegie's fundamental belief in people touches at the core of MCR Safety’s very existence. We protect countless US workers from hazardous working conditions. Many of the workers we protect work in Primary Metals, the steel industry Carnegie helped build.

We covered iron ore in Metal Mining, which is the core ingredient used across this industry. Instead of extracting iron minerals from the earth, this industry's companies physically take the iron ore and manufacture products from hot metal. This activity typically involves refining metals and casting molten metal into desired shapes. The end product sold by these companies range from hot and cold steel, metal parts, stainless steel, aluminum bars, tubes, sheets and plates. This transformed metal fills the demand from industries that manufacture motor vehicles, aircraft, machinery, metal containers, and construction steel.

The industry is broken up into four sub-industries:

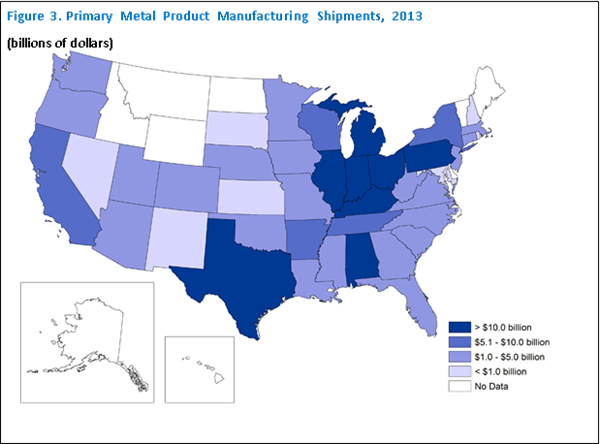

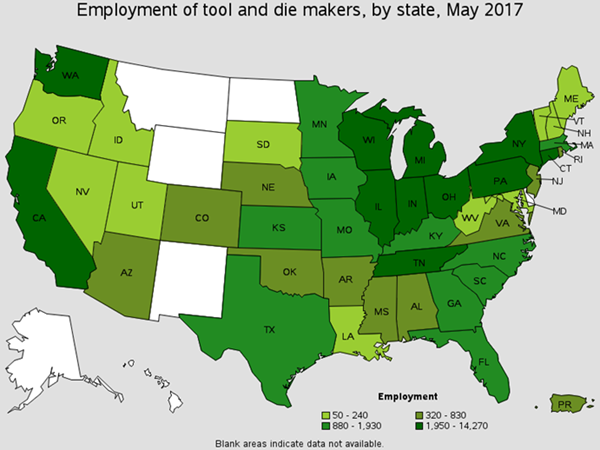

Much of the economic activity from these sub-industries materializes across US Midwestern states. Here is a look at the most active states for this industry.

Census Bureau’s US map showing states heavily engaged in primary metal manufacturing.

BLS breakdown of the US counties employing the most workers.

Indiana employs the most workers, with Ohio and Pennsylvania followed close behind.

The Primary Metals industry employs roughly 365,000 workers, with many of the workers facing hazardous working conditions almost every day. Consider the fact that the average recordable case is 2.9 across all private industries. The primary metal industry comes in at 4.5, which means there are many risks and hazards faced. This is ultimately where MCR Safety enters the picture.

MCR Safety's products protect people, allowing hard working people to return home everyday in one piece. We breakdown many of the hazards from each sub-industry, with the aim of keeping you safe! But first, you might be wondering whether your specific industry is truly hazardous. Here is the BLS breakdown of the sub-industries with the most recordable cases:

MCR Safety's products protect people, allowing hard working people to return home everyday in one piece. We breakdown many of the hazards from each sub-industry, with the aim of keeping you safe! But first, you might be wondering whether your specific industry is truly hazardous. Here is the BLS breakdown of the sub-industries with the most recordable cases:

| Sub-Industry | Total Recordable cases, per 100 full-time employees |

|---|---|

| Aluminum Foundries (except die-casting) | 7 |

| Steel Foundries (except investment) | 6.9 |

| Steel Wire Drawing | 6.7 |

| Non-Ferrous Metal Foundries | 6.3 |

| Iron Foundries | 6.1 |

| Ferrous Metal Foundries | 6 |

| Rolling and Drawing of Purchased Steel | 5.8 |

| Rolled Steel Shape Manufacturing | 5.4 |

| Iron and Steel Pipe and Tube Manufacturing from Purchased Steel | 5 |

| Secondary Smelting and Alloying of Aluminum | 5 |

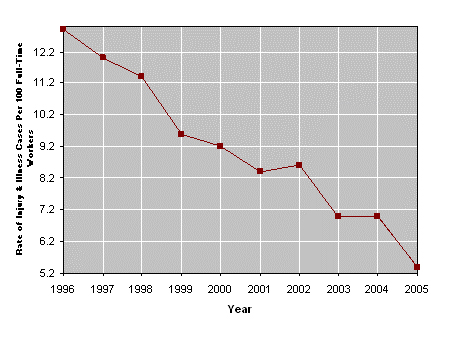

There is some overall good news; recordable injuries have been coming down over the past 30+ years. The next graph highlights how injuries have drastically come down since 1996.

Rate of Injury & Illness Cases Per 100 Full-Time Employees

Our aim is to make sure these recordable cases continue to drop. We make this happen by manufacturing premier safety gear designed for the Primary Metals industry, while also educating users on the hazards the industry faces. Before we jump into discussing the hazards, here is a quick look at the occupations you will find within the primary metal industry:

Click an occupation to expand and learn more.

Assemble finished products and parts. There are around 5,000 of these workers found in Primary Metals. You will find this worker assembling bolts, using many different types of tools, and moving heavy parts. They construct finished products and the parts that go into them. Assemblers and Fabricators use alot of tools, machines, and most importanly need their hands protected.

Keep the inside of the clean and the outside kept trimmed. There are around 1,200 of these workers found in Primary Metals. You will find this worker keeping building clean, orderly, and in good condition. Often times, they will be gathering and empty trash, sweeping, and cleaning up spills Common job title is Janitor.

Conduct chemical or physical laboratory tests to assist scientists. There are around 980 of these workers found in the Primary Metals industry. You will find this worker preparing chemical solutions and cleaning laboratory equipment. Common job title for this occupation are Chemical Analyst, Lab Tester, QC Technician.

Operate machines to coat or paint metal. There are around 6,300 of these workers found in the Primary Metals industry. You will find this worker filling hoppers with paint and directly spraying paint. Common job titles are Coater Operator, Paint Technician, and Spray Painter.

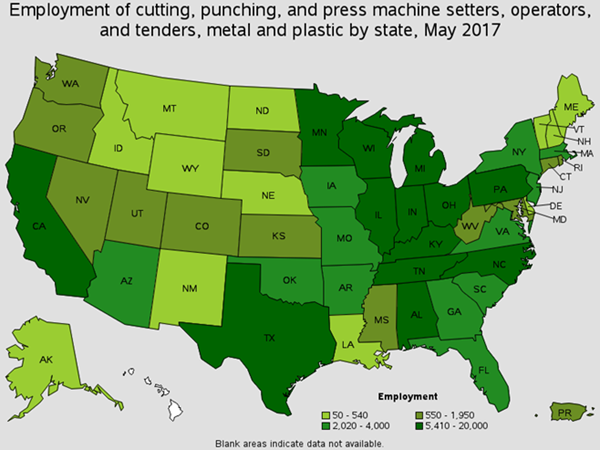

Employment of Cutting, Punching, and Press Machine Setters/Operators by State

Operate computer-controlled machines or robots to perform machine functions on metal. There are around 6,300 of these workers in the Primary Metals industry. You will find these workers removing metalwork pieces and installing metalwork pieces. Common job titles for this job occupation are Brake Press Operator, Machine Operator, and CNC Operator.

Perform tasks involving physical labor at construction sites. There are roughly around 6,300 of these workers found in Primary Metals. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common job titles for this occupation are Helper, Laborer, Post Framer, and Construction Worker.

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 13,000 of this occupation in Primary Metals. You will find these workers aligning metal parts and grinding out burrs or sharp edges. This makes cut resistant gloves a high priority for this worker. Common Job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, Press Punch Operator.

Operate drilling machines to drill, bore, ream, and mill metal work pieces. There are around 1,390 of these workers found in the Primary Metals industry. Y ou will find this worker installing tools in spindles, changing worn cutting tools, and replacing worn out equipment. Common job titles for this position are Bore Mill Operator, Drill Press Operator, Driller.

Install, maintain, and repair electrical wiring, equipment, and fixtures. Around 4,700 of this occupation is found in Primary Metals. You will find these workers connecting wires to breakers and transformers, making dielectric and FR safety gear important. Common Job titles for this position are Industrial Electrician, Journeyman Electrician and Wireman, and Maintenance Electrician.

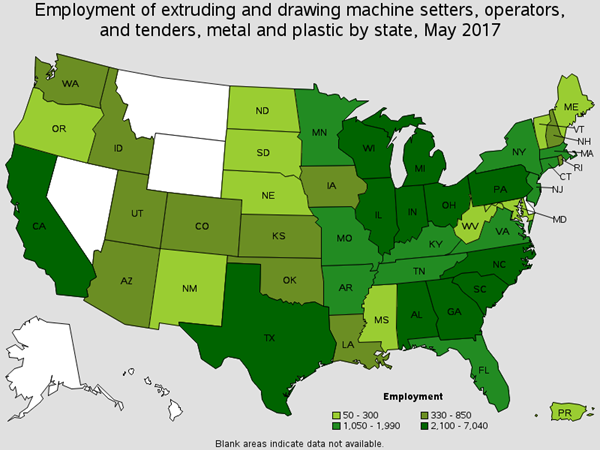

Operate machines that extrude metal materials into tubes, wires, and bars. Around 13,960 work in the Primary Metal industry. You will find these workers loading materials into machines. Common Job titles for this position are Extruder Operator, Wire Mill Remover, Extrusion Press Operator and Metal Inspector.

Employment of Extruding and Drawing Machine Settings/Operators by State

Operate machines to taper, shape and form metal. Around 7% of the workforce falls into this occupation, around 26,420 workers. You will find these workers removing dies, forging hammers and moving metal work pieces. Common Job titles for this position are Forger, Blacksmith, Hammer Operator, and Forge Presso Operators

Operate or tend heating equipment other than basic metal, plastic, or food processing equipment. There are around 930 of these working in the Primary Metals industry. You will find these workers handling, moving objects and clearing equipment jams. Common Job titles for this position are Dry Kiln Operator, Dryer Feeder, and Overn Operator.

Operate grinding tools that remove excess metal material or burrs. There are around 10,830 of these workers are in Primary Metals. You will find these workers sharpening edges and corners, along with polishing metal. Common Job titles for this position are Deburrer, Finisher, Grinder, and Grinding Operator.

Operate heat treating equipment, such as induction and flame-hardening machines. There are around 3,000 of these workers in the Primary Metals industry. You will find these workers opening furnace doors to load stock and handling many materials. Common Job titles for this position are Burner, Batch Heater Operator, and Heat Treater.

Duties include supplying or holding materials, along with cleaning work areas and equipment. Around 9,420 of these workers are in the Primary Metals industry. You will find these workers attaching cables, changing machine gears and handling a lot of material. All of these activities make gloves extremely important. Common Job titles for this position are Laborer, Press Helper, and Material Handler.

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 13,000 of these workers are in the Primary Metals industry. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Lubricates machines, changes parts, and performs machinery maintenance. There are a little over 19,900 of these workers in the Primary Metals industry. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Inspect machined, fabricated or assembled parts. There are around 14,000 of these workers in the Primary Metals industry. Half of these workers are found in foundries. You will find these workers inspecting equipment and structures. Common Job titles for this position are Quality Technician, Inspector, and Picker / Pacer.

Workers move materials, objects and stock. There are around 13,250 of these workers in the Primary Metals industry. Machine feeders also fall into this worker group. You will find this occupation loading docks and materials to production areas. Common Job titles for this position are Line Tender, Laborer, and Materials Handler. Due to the use of one’s hands, wearing gloves is a must.

Feed and remove materials into machines or equipment. There are around 1,700 of these workers found in the Primary Metals industry. You will find this worker handling, installing moving and positioning materials. Common job titles for this position are Feeder, Lug Loader, Sawmill Worker.

Operate cutting and forming machines. Roughly, 7.5% of the workforce falls into this occupation, roughly 30,000 workers. The majority of these workers are employed in Aluminum production. You will find these workers changing cutting tools, aligning parts, and inspecting metalwork pieces. Common Job titles for this position are CNC Machine setter, CNC machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

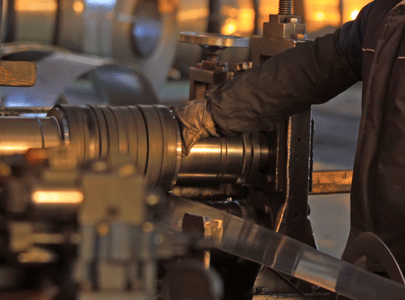

Machinists are the workers who utilize the machine and cutting tools. This occupation is highly skilled at operating machinery. There are around 9,000 of this occupation working in Primary Metals. You will find this worker operating machine tools to produce precision parts. Job titles for this position Gear Machinist, Machine Operator and Maintenance Machinist.

Operate lathe and turning machines to turn, bore, thread, form, or face metal, such as wire, rod, or bar stock. There are around 1,500 of these workers found in the Primary Metals industry. You will find these workers replacing worn tools, sharpening dull cutting tools and using cutter-grinding machines. Common job titles for this occupation are Laborer and Operator.

Help move steel and other materials. Around 26,000 of these workers are found in the Primary Metals industry. That is a large number of hands needing protected. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

Operate machines designed to cut, shape and form metal. There are roughly 146,000 of this occupation found in Primary Metals. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Be sure to check out our Metal Fabrication industry educational page.

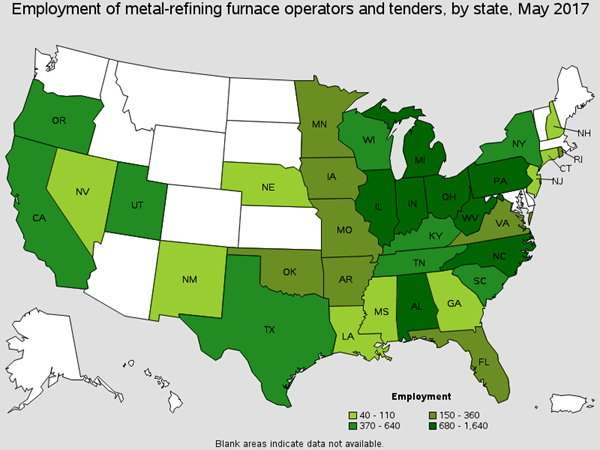

Operates furnaces that melt and refine metal before casting or for constructing various types of steel. Furnace types include gas, oil, coal, electric arc or electric induction, open-hearth, or oxygen furnaces. There are roughly around 21,470 of these workers in the Primary Metal industry. Around 24% of the entire US occupation works in Iron and Steel mills and 17.8% in Aluminum production. You will find these workers draining, transferring, and removing molten metal from furnaces and then placing into molds. Common Job titles for this position are Melt Room Operator, Vessel Operator and Central Melt Specialist.

Employment of Metal-Refining Furnace Operators and Tenders by State

Operate machines to mill, plane, shape, and groove metal. There are around 4,000 of these workers found in the Primary Metals industry. You will find this worker eeding materials and mounting materials into production equipment. Common job titles for this occupation are Machine Operator and Miller.

Install, dismantle, or move machinery and heavy equipment. There are around 1,900 of these workers found in the Primary Metals industry. You will find this worker adjusting bolts, positioning parts, using hand tools, and drilling holes. Common job titles for this occupation are Maintencance Mechanic and Precision Millwright.

Lay out, machine, fit, and assemble castings and parts to metal patterns, core boxes, or match plates. There are around 1,130 of these workers found in the Primary Metals industry. You will find this worker assembling patterns using hand tool and operating grinding equipment. Common job titles for this occupation are Layout Technician, Metal Pattern maker, and Wax Molder.

Operate casting or coremaking machines to mold or cast metal. You will find this worker operating casting, coremaking and metal forming equipment. Common Job titles for this position are Core Machine Operator, Mold Technician, and Die Cast Technician.

Make wax or sand cores / molds used in the production of metal castings in foundries. There are around 10,980 of these workers found in the Primary Metals industry. You will find this worker cleaning and smoothing molds, positioning wires, and spraying parting agents. Common job titles for this position are Core Setter, Core Setter, and Sand Molder.

This occupation makes many of the PPE related decisions within a mine. They review, evaluate, and analyze work environments. This occupation also design programs and procedures to control, eliminate, and prevent disease or injury caused by chemical, physical, and biological agents or ergonomic factors. There are roughly around 981 of these workers found in Primary Metals. You will find these workers recommending safety measures and evaluating workplace safety equipment. Common Job titles for this position are Certified Industrial Hygienist; Chief Safety Officer; Corporate Safety Director; Director Employee Safety and Health; Environmental Health and Safety Manager; Environmental, Health, and Safety EHS Officer; Health and Safety Manager; Risk Control Consultant; Safety Consultant; Safety Specialist

Operate machines preparing products for storage or shipment. There are around 1,230 of this occupation found in Primary Metals. You will find these workers inspecting products and removing packaged items. Job titles for this position are Machine Operator, Packaging Operator, and Fabrication Technician.

Operate coating machines to coat metal or plastic products with chromium, zinc, copper, cadmium, nickel. There are around 1,400 of these workers found in Primary Metals. You will find this worker immersing workpieces in coating solution. Common Job titles for this occupation are Anodizer, Coater Operator, Galvanizer, Plater.

Pour and regulate the flow of molten metal into molds. There are around 7,000 of these workers in Primary Metals. Are 56% of Pourers and Casters work in foundries. You will find these workers placing materials in molds, moving materials and manipulating things. Common job titles are General Caster, Foundry Worker, Furnace Operator, and Iron Pourer. Around 56% of this entire US occupation can be found in foundries.

Operate machines that plate, roll and flatten steel. There are roughly 10,000 of these workers found in the Primary Metals industry. Around 28% of this entire US occupation works in Iron and Steel mills and another 10% in steel manufacturing. You will find these workers around shears, grinders and adjusting machines. Common Job titles for this position are Rolling Mill Operator, Mill Operator and Roll Form Operator.

Lay out metal stock, operates machine tools, and assembles parts to make and repair dies. There are roughly 3,400 of these workers. You will find these workers cutting and shaping meta, along with assembling machine fixtures. Common Job titles for this position are Die Maker, Die Machinist, and Tool Repairer.

Employment of Tool and Die Makers by State

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 7,050 of these workers employed in Primary Metals. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. There are around 830 of these workers found in Primary Metals. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

We know we have thrown a lot of industry information at you. Our goal is empowering you with information designed to keep you safe at work!

"Do not wait to strike till the iron is hot, but make it hot by striking."

Let’s get you covered with the safety gear needed for striking that hot metal at work!

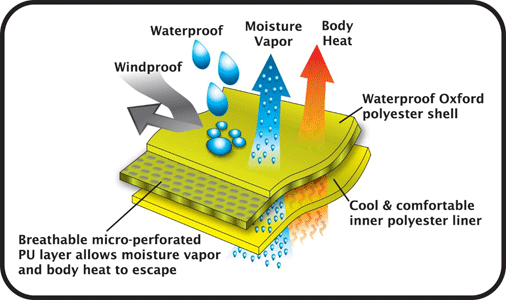

Learn more about MCR Safety product features that protect against these common hazards.

Click "Learn More" to find info on protecting yourself against these hazards and find the right gear for the job.

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.