A single Boeing 747 contains 147,000 pounds of Aluminum!

Good thing aluminum is the second most bountiful metallic element in Earth’s crust after Silicon.

Aluminum is referred to as the “Miracle Metal”, due to it being extremely versatile, lightweight, durable, recyclable and corrosion resistant. This metal is a third the weight of steel, making it ideal for innovating flexible product designs. With so many unique characteristics, it has helped shaped industries ranging from consumer packaging, construction, aircraft, automobile and aerospace.

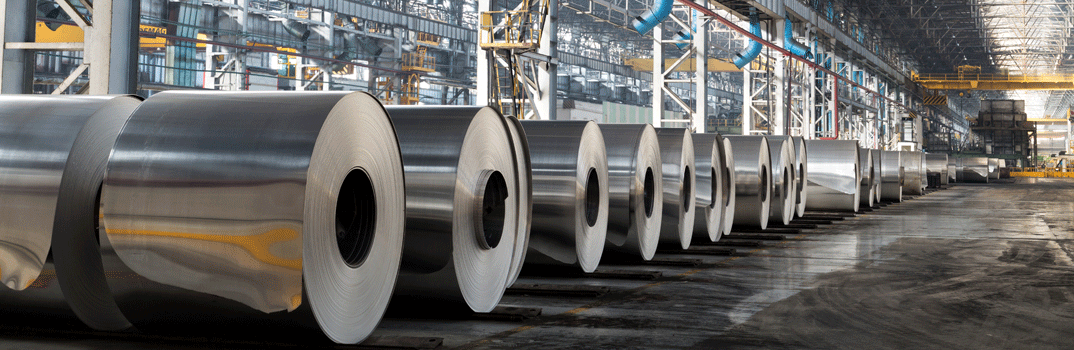

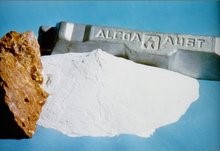

Aluminum production is an industry in itself, with aluminum sheets, plates and foils representing over 16.5 billion in shipments. It consists of several different stages.

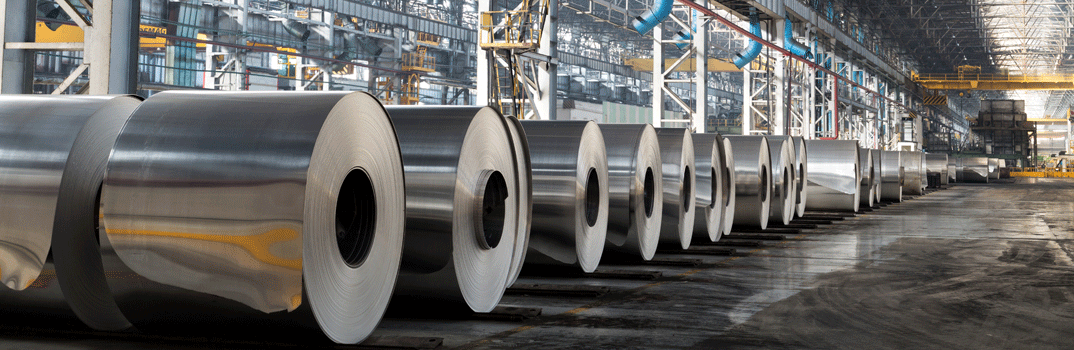

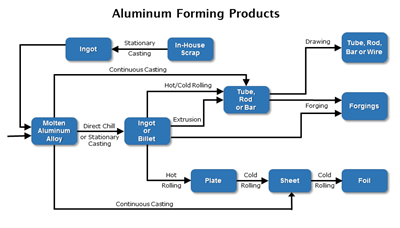

Small look into the process and what goes in to making this versatile metal

Click the image for a larger view

The aluminum industry involves companies operating in one of these areas:

Primary reduction plants electrolytically reduce refined bauxite to form aluminum.

bar, foil, pipe, plate, rod, sheet, tube, wire.

Storage of Newly Created Aluminum

Harvesting Aluminum Scrap

Aluminum originates from bauxite, an ore found in tropical areas.

EPA flowchart for various Aluminum formed shapes

Companies that flat roll continuous casting sheet, plate, foil and welded tube from purchased aluminum. Products are manufactured for finished products, likes ships and aircraft. Aluminum sheets make up the 3rd highest metal shipments from the entire Primary Metal industry.

Aluminum roofing sheets

Companies that extrude aluminum and aluminum base alloy basic shapes – rods, bar, pipe and tubes. Extrusions are used for forging and drawing to fabricate products like car bumpers, beams, and tubing.

Extruding Profiles

Companies engaged in casting and pouring molten aluminum into a mold. Forged products are used as parts in machinery, aircraft and engines.

Casting Aluminum

Companies engaged in recovering aluminum and aluminum alloys from scrap. Out of all Aluminum sub-industries, this one experiences the most recordable injury cases. Manual handling of scrap metal is a leading cause of these injuries.

Aluminum extrusion scrap

Motorcycle equipment, electronic equipment and automotive equipment, tubes, bottles, helmets, beverage cans, packaging, and trays.

Beverage Cans

For all the wonderful aluminum products to exist, someone has to make it happen. Around 56,000 employees work with nonferrous metal operations. Here are the workers most likely needing Personal Protective Equipment (PPE) and safety gear:

Click an occupation to expand and learn more.

Operate computer-controlled machines or robots to perform machine functions on metal. There are around 990 of these workers found in the Aluminum industry. You will find these workers removing metalwork pieces and installing metalwork pieces. Common job titles for this job occupation are Brake Press Operator, Machine Operator, and CNC Operator.

Perform tasks involving physical labor at construction sites. There are roughly around 1,400 of these workers found in the Aluminum industry. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common job titles are Helper, Laborer, Post Framer, and Construction Worker.

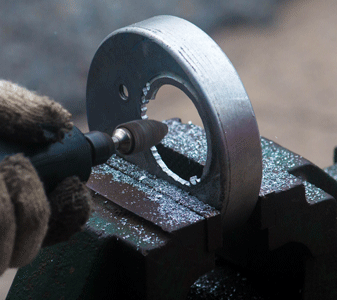

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 4,250 of this occupation in the Aluminum Industry. You will find these workers aligning metal parts and grinding out burrs or sharp edges. This makes cut resistant gloves a high priority for this worker. Common Job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, Press Punch Operator.

Install, maintain, and repair electrical wiring, equipment, and fixtures. Around 1,040 of this occupation found in the Aluminum industry. You will find these workers connecting wires to breakers and transformers, making dielectric and FR safety gear important. Common Job titles for this position are Industrial Electrician, Journeyman Electrician and Wireman, and Maintenance Electrician.

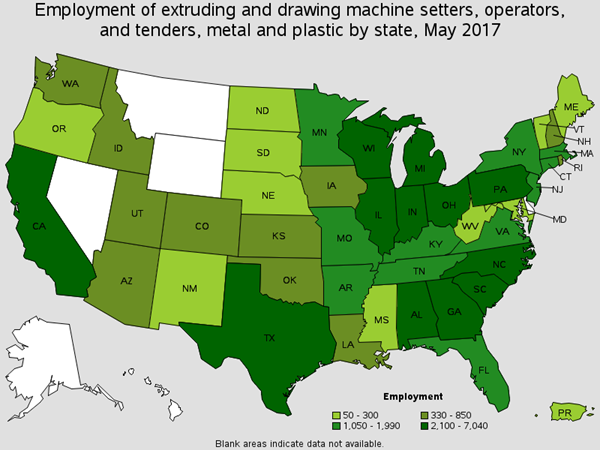

Operate machines that extrude metal materials into tubes, wires, and bars. Around 3,360 of this occupation are found in the Aluminun Industry. You will find these workers loading materials into machines. Common Job titles for this position are Extruder Operator, Wire Mill Remover, Extrusion Press Operator and Metal Inspector.

Employment of Extruding and Drawing Machine Setters & Operators by State

Operate machines to taper, shape and form metal. There are around 4,260 of these workers found in the Aluminum Industry. You will find these workers removing dies, forging hammers and moving metal work pieces. Common Job titles for this position are Forger, Blacksmith, Hammer Operator, and Forge Presso Operators

Make wax or sand cores / molds used in the production of metal castings in foundries. There are around 1,040 of these workers found in the Aluminum industry. You will find this worker cleaning and smoothing molds, positioning wires, and spraying parting agents. Common job titles for this position are Core Setter, Core Setter, and Sand Molder.

Duties include supplying or holding materials, along with cleaning work areas and equipment. Around 1,700 of these workers are in the Aluminum Industry. You will find these workers attaching cables, changing machine gears and handling a lot of material. All of these activities make gloves extremely important. Common Job titles for this position are Laborer, Press Helper, and Material Handler.

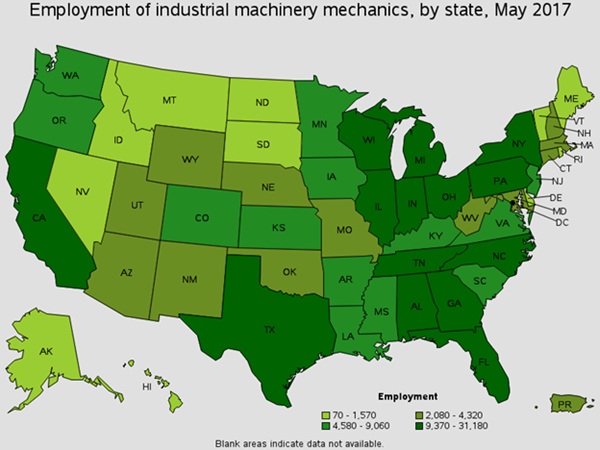

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 2,500 of these workers in the Aluminum industry. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Employment of Industrial Machinery Mechanics by State

Lubricates machines, changes parts, and performs machinery maintenance. There are around 3,380 of these workers in the Aluminum industry. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Operate cutting and forming machines. There are roughly 5,330 of these workers in the Aluminum industry. The majority of these workers are employed in Aluminum production. You will find these workers changing cutting tools, aligning parts, and inspecting metalwork pieces. Common Job titles for this position are CNC Machine setter, CNC machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

Machinists are the workers who utilize the machine and cutting tools. This occupation is highly skilled at operating machinery. There are around 1,240 of this occupation working in the Aluminum industry. You will find this worker operating machine tools to produce precision parts. Job titles for this position Gear Machinist, Machine Operator and Maintenance Machinist.

These workers help move steel and other materials. There are around 5,390 of these workers in the Aluminum indusry. That is a large number of hands needing protected. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

Operate machines designed to cut, shape and form metal. There are roughly 19,490 of these workers found in the Aluminum industry. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Be sure to check out our Metal Fabrication industry educational page.

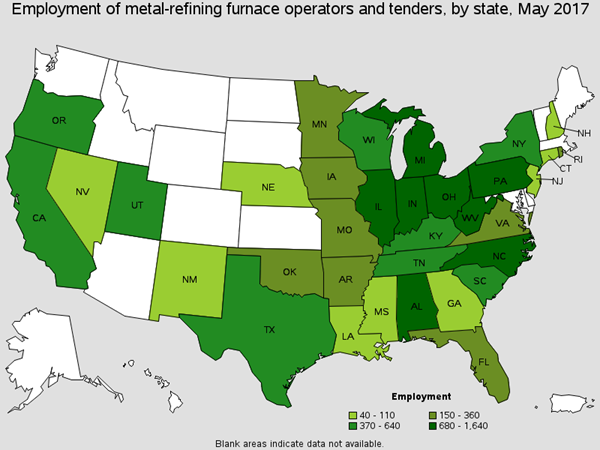

Operates furnaces that melt and refine metal before casting or for constructing various types of steel. Furnace types include gas, oil, coal, electric arc or electric induction, open-hearth, or oxygen furnaces. There are roughly around 2,920 0 of these workers in the Aluminum industry. You will find these workers draining, transferring, and removing molten metal from furnaces and then placing into molds. Common Job titles for this position are Melt Room Operator, Vessel Operator and Central Melt Specialist.

Employment of Metal-Refining Furnance Operators & Tenders by State

Operate casting or coremaking machines to mold or cast metal. Roughly 1,040 of this occupaiton is found in the Aluminum industry. Common Job titles for this position are Core Machine Operator, Mold Technician, and Die Cast Technician.

Pour and regulate the flow of molten metal into molds. There are around 960 of these workers in the Aluminum industry. Around 56% of this entire US occupation can be found in foundries. ou will find these workers placing materials in molds, moving materials and manipulating things. Common job titles are General Caster, Foundry Worker, Furnace Operator, and Iron Pourer.

Operate machines that plate, roll and flatten steel. There are around 830 of these workers are found in the Aluminum industry. Common Job titles for this position are Rolling Mill Operator, Mill Operator and Roll Form Operator.

In addition to Aluminum, there are 57,000 more employees that work with other nonferrous metal operations, like Silver, Platinum, Gold, Copper, Nickle Titanium, Tin, and Zinc. Similar workers, as to those mentioned above, are found across these metal operations.

"Working safely may get old, but so do those who practice it."

Our goal is to make sure you stay safe and live well into your older years. Whether an employee is working in an aluminum refinery, handling scrap metal or rolling copper, there are dangerous hazards workers face. Lets show you some of the safety gear designed for these hazards.

Find the right MCR Safety product that protects you against these common hazards.

Bending aluminum can easily lacerate a worker's hands. Check out our cut resistant gloves.

Learn More About Bending Aluminum Protection

Aluminum can easily irritate the skin. Flourides and caustics are definite concerns. Check out the chemical protection offered.

Learn More About Chemicals and Liquids Protection

Mechanics undertaking regular maintenance on mechanical systems can easily get their hands banged up. Our impact gloves are perfect for this type of work.

Learn More About Crush and Impact Protection

DuPont Kevlar gloves provide the thermal and cut protection required for many aluminum applications.

Learn More About Cut and Heat Protection

Sharp edges and sharp material is this worker's primary concern.

Learn More About Cutting Aluminum Protection

Rough edges and material requires well constructed safety gear.

Aluminum melts at 1,221°F. 6X greater Anti-Fog face shields and goggles, along with leather protectors, are excellent for protecting against metal splashes.

Goggles, Face Shields, and Protective eyewear are excellent choices when working around toxic substances and flying fragments, like found in the Aluminum industry. Check out all our eyewear options offered on our eyewear protection page.

Learn More About Impaired Vision Protection

Disposable gloves are excellent for finishing metal by maintaining high dexterity levels and keeping metals clean.

Learn More About Metal Preperation Protection

Moving material workers need to stay visible around high-traffic facilities transporting heavy aluminum.

Learn More About Overall Visibility Protection

MCR Safety's cut resistant gloves are made with high performance yarns such as DuPont Kevlar and DSM Dyneema.

Learn More About Sharp Objects Protection

When spraying aluminum, workers need waterproof gloves, lined eyewear and protective garments.

Welding aluminum required filtered eyewear, premium leather gloves and 6X greater AF face shields.

Learn More About Welding Protection

The saying goes, "You don't know what you don't know". Let our 360 team help you know more abut PPE.

Learn More About Lack of Safety Knowledge Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.