MCR Safety has been manufacturing Personal Protection Equipment (PPE) since 1976, well over 40 years. We expanded our footprint into flame-resistant FR protection back in 2014, offering even more of the complete PPE solution users demand. Since then, we've continued elevating our product offerings, applying unmatched patented technology.

Based on our experience, we know users, companies, and our distributors rely on quality product information. MCR Safety is dedicated to keeping workers safe, protected, and informed! With that focus, we work hard to keep users aware of both the types of PPE we manufacture and how PPE is used across specific industries. When you have an important purpose like ours, protecting workers, there is no other choice. At MCR Safety, we are driven by our motto: We Protect People

Einstein once said, “Education is not the learning of facts but the training of the mind to think.” We want you to think about your safety at work, not just remember product facts like PPE category levels, fabric properties, or standards met! To meet this goal, we’ve created a dedicated resource page on FR Protection, a central place for all things safety-related that pertain to FR. On our FR Protection page, you will find illustrations, statistics, product specs, and much more. It’s all built around a drive for excellence in keeping you safe at work, home, and anywhere hazards exist.

You may opt to continue reading to learn more about fire injury statistics, fire hazards, industries requiring FR protection, and top BLS injuries; or, you can simply click the MCR Safety FR Clothing logo below and be taken directly to the safety section for this industry, its suggested PPE, and a list of potential hazards.

If there is one workplace hazard you don’t want to take chances with, it is fire. In fact, there are enough alarming statistics around this subject, we’ve included them on their own page.

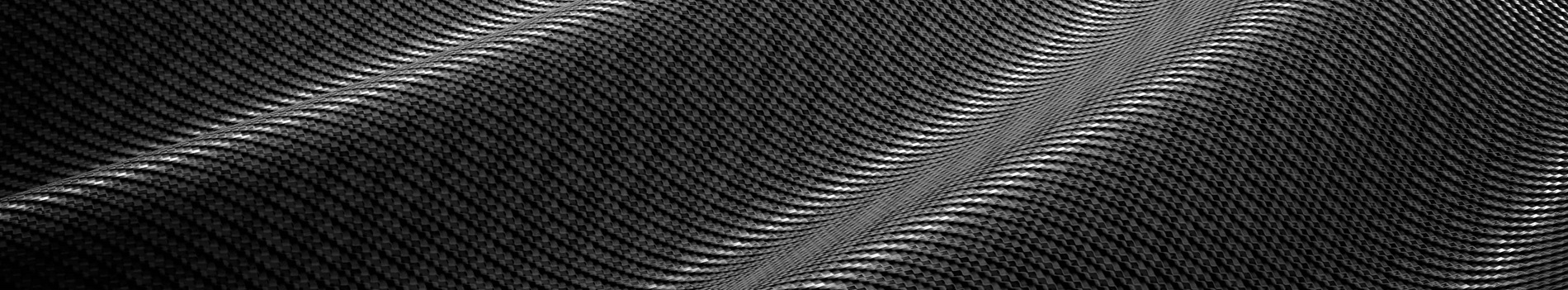

Values (in billion $) and percentage shares of the components of the total cost of fire ($328.5 billion) in

the U.S. in 2014.

Over 10% of the total costs involve injuries and loss of life.

The statistics highlighted above and our dedicated workplace statistics page clearly show fire hazards are not to be treated lightly by anyone. To safeguard workers, employees who work in high-risk areas that involve fire concerns are required to wear flame-resistant clothing, also referred to as FRC.

Flame-resistant (FR) protective equipment addresses the essential issue of guarding against open flames and sudden flashes. These include things like arc flashes, arc blasts, fires, explosions, and related burns.

The two most common hazards FR clothing and garments protect against are flash fires and electric arc flash, which we cover in-depth on dedicated resource pages. It is important to determine which FR hazards are present on your job site, as different fabrics and testing are geared towards specific hazards. For example, flash fire testing is best highlighted by NFPA 2112, whereas arc flash hazards are best represented by electric arc testing.

Electric current passes through the air between ungrounded and grounded conductors. Temperatures may reach 35,000°F. Electricians and electric utility linemen are those who need to pay close attention to 70E updates and HRC levels.

Fine dust particles that, when present in the air at certain amounts and under the right conditions, can cause dangerous flash fires, deflagrations, and explosions. Industries such as pulp and paper, food processing plants, plastics manufacturing, pesticide manufacturing, and many more must protect workers from combustible dust.

OSHA defines a flammable liquid as any liquid having a flash-point below 140°F and having a vapor pressure not exceeding 40 pounds per square inch (absolute) at 100°F.

Flash fire is a sudden, intense, rapidly moving flame that occurs in an environment where fuel, vapors, dust, and air combust. The vapors or particles that ignite and explode pose a serious threat to workers, causing extensive harm to both equipment and people. Flash fires are a major concern for refineries, chemical manufacturing, and pharmaceuticals.

Have undergone a change from a solid to a liquid metal. Working around it presents a challenge for workers as non-flame resistant clothing may potentially ignite and combust. Westex recommends a minimum weight of 12 oz/yd2 or heavier fabric for most foundry and molten metal applications.

Open flames are defined as devices such as candles, boilers, heating units, torches, butane burners, and any other flame producing device. Anyone working around open flames, such as those operating portable torches, should be wearing FR clothing.

Hot work is any process involving flame, spark, or heat production. This includes cutting, burning, welding, grinding, chipping, drilling, and torch-applied roofing. The National Fire and Protection Associations NFPA shows the following workers most at risk for this hazard: construction contractors, ironworkers, sheet-metal workers, roofers, pipe-fitters, utility workers, plumbers, electrical workers, and welders.

As shown above, there are endless workplace hazards that have the potential to ignite a worker's clothing, causing burn injury and potential loss of life. For this reason, a hazard risk evaluation of the workplace should always be conducted by employers to help determine the necessary protection levels of FR clothing. In addition, the type of fabric neeeded will change depending on the type of hazard faced. An example of this would be using Westex Vinex® fabric when working at aluminum companies.

While we can't mandate a company's PPE requirements, we can shed light on the hazards workers are likely to face within particular industries and the common fire injuries that occur in each. MCR Safety also offers a 360 assessment to assist safety managers in choosing the proper FR clothing for their workers.

FR clothing is especially important in industrial applications, as it provides workers with PPE designed to help them survive the dangerous fire hazards possible in a variety of industries. Due to the recent NFPA 652 ruling regarding combustible dust, many industries are now increasing their use of FR apparel. For example, in the automotive industry, maintenance and electricians in automotive plants have begun wearing FR clothing to better protect themselves in the workplace.

Chemical manufacturing facilities are always at risk of fires due to the processes involved. Flash fires and explosions are always a concern for worker safety. Beyond just the flammable chemicals, workers are exposed to high temperatures, pressurized gases, and hot surfaces.

Pulp and paper workers face the constant threat of combustible dust and flash fire hazards.

The manufacturing of synthetic resins involves flammable gases and dust. Fires and explosions are a common hazard in plastic manufacturing.

Welding fires are caused by sparks, hot slag, and torch flames. Be sure to check out our Welding Protection page for all your PPE options. Heavier weight FR clothing, along with leather apparel, is worn during most welding applications.

Anyone working around electricity is at risk of electric arc hazards. Almost all field personnel working in the electric utility industry requires FR clothing.

Oil and gas extraction workers face a constant risk of fire and explosions due to the potential ignition of flammable well gases and vapors.

Automotive plants have a lot of electrical maintenance that takes place on the production line machinery. FR clothing as a PPE requirement is gradually being accepted by more and more automotive companies to help keep workers safe.

Electrical contractors should always wear FR gear, as 22 percent of their workplace accidents are the result of electrical fires.

Fires and explosions pose a serious threat to the safety of miners. Many consider fires in mines as one of the most devastating industrial disasters to occur.

Due to the large volume of ammonium nitrate, a fire at a fertilizer plant is highly concerning for safety managers in this industry.

The failure of refining equipment is a frequent cause of fires in refineries. Flash fires are always a concern for these workers.

FR clothing is required by many workers who maintain signals and switches in the railroad and transportation industry. These workers regularly encounter high voltage electricity.

Food processing facilities are prone to combustible oils, explosive dust, and flammable liquids. The largest number of fire losses occur in grain mill products manufacturing facilities, slaughterhouses, and bakeries. The major sources for fires are cooking equipment and open flames.

Ingredients found in the production of prescription drugs are combustible. Workers in the pharmaceutical manufacturing industry require FR protection to guard against injury from fires or explosions.

Iron and steel mills have combustible materials that can quickly catch fire. FR protection should be worn by all employees.

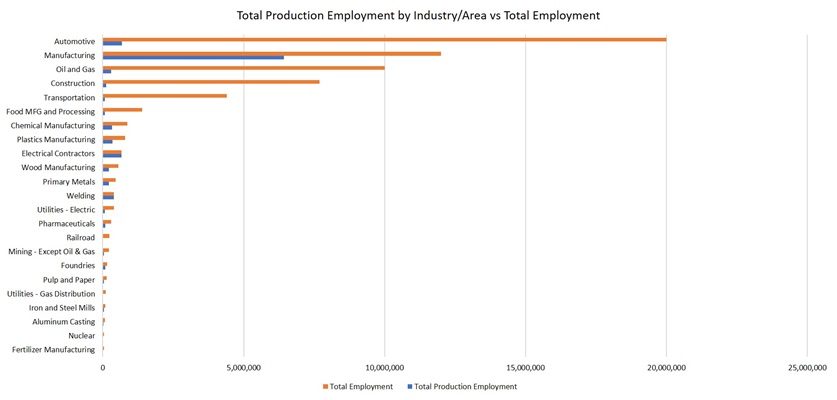

There are a number of industries that require FR protection. This chart of recent Bureau of Labor Statistics (BLS) production employment numbers illustrates the trend in FR protection. Those workers on the production line or “in the trenches” of these industries need to be protected from fire hazards.

Certain industries are more dangerous than others, especially in the world of fire hazards. Here is what the BLS shows as the industries likely to be exposed to hazards requiring FR protection.

There were a total of 123 fatal injuries involving fire and explosions. Here is a breakdown of the industries experiencing the most injuries:

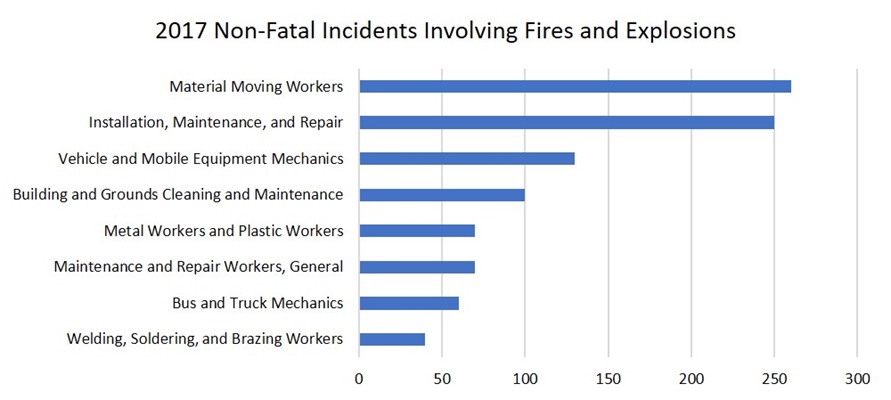

There were a total of 1,470 non-fatal injuries involving fire and explosions. Here is a breakdown of the industries experiencing the most injuries:

Knowing the BLS risk factors goes a long way in protecting workers. For one, it helps identify areas within a facility that need extra safeguards in place. Safety managers can minimize risks to employees working in areas known to have high rates of flame injuries and ensure correct apparel is worn. Second, it ensures workers know ahead of time where they need to be extra cautious.

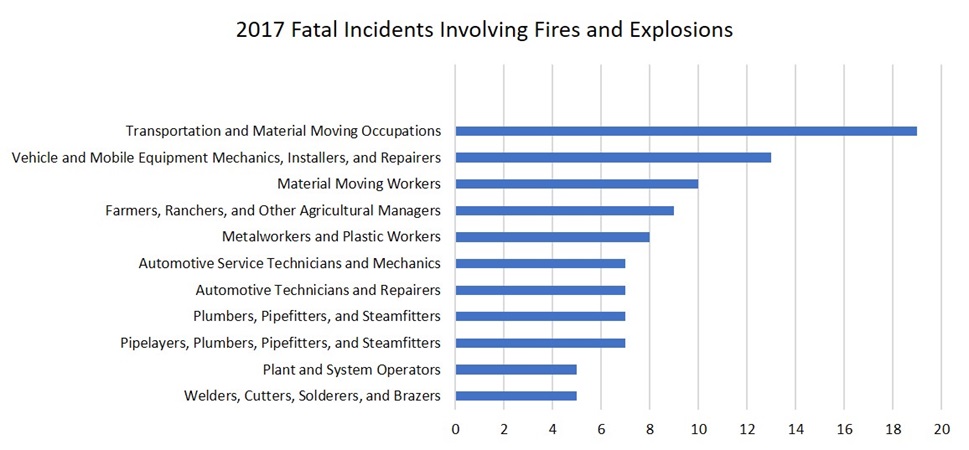

Within each industry, there are certain occupations that are injured more than others. There were a total of 123 fatal injuries involving fire and explosions. Here is a breakdown of the occupations experiencing the most injuries:

There were a total of 1,470 non-fatal injuries involving fire and explosions. Here is a breakdown of the occupations experiencing the most injuries:

You might be familiar with the way we reference cut protection on other pages: there is no cut-proof glove. Well, there is no FR clothing that is fireproof. The primary function of FR clothing is to limit burn injuries sustained by workers.

Here are some of the most important reasons workers wear flame-resistant (FR) clothing:

OSHA states that flame-resistant clothing “is a type of apparel that is made out of material that is meant to self-extinguish once the ignition source has been removed.” There is a plethora of FR garments available that meet this requirement. They come in a variety of garment types and styles.

MCR Safety offers a wide range of FR garments, utilizing a variety of different fabrics certified to numerous FR standards. Click on any image to immediately start viewing available styles.

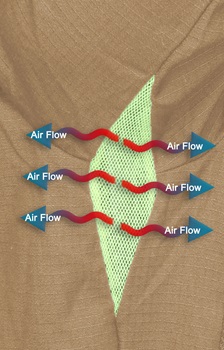

At MCR Safety, we always want you dressed head-to-toe in the best PPE available on the market. The daily demands of your job take a physical toll on you and the PPE you wear. On our Summit Breeze® resource page, we cover this new state-of-the-art technology more in-depth. For now, let us just leave you with the following:

Features…features…and more features! We all love features… Right? When someone finds themselves engulfed in flames, the last thing they want is to get stuck in their garment due to a faulty zipper. Can you save some money with a less expensive zipper or less stitching found on some of our competitors’ FR clothing? Yes, you can. However, the better question to ask is do you want to reduce features, fabric quality, or technology knowing the fire risks workers face? As we point out on the Flash Fire performance page, a burn injury costs well above $200,000 on average. Reducing features is not recommended to cut corners with this hazard.

It may sound a little dramatic, but wearing flame-resistant clothing (FRC) that exceeds performance requirements for burn rate, fabrics, zippers, pockets, and buttons may be the difference between life and death. Here are some of the features to pay attention to when selecting an MCR Safety FR garment. Across each dedicated FR product page, you will find a list of three features that separate this type of product from the crowd.

We know FR safety clothing can be personal in nature and workers’ needs vary. This is why we offer a wide range of FR garments, including jackets, jeans, shirts, coveralls, and overalls. Our goal, as stated in the beginning, is one thing – protect you from workplace hazards.

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.