MCR Safety's welding products are designed to keep welders safe from numerous workplace hazards. From leather gloves and flame-resistant clothing, to sateen cotton and eyewear, we have a multitude of options to fit your protective needs. Below, you can learn more about welding: the industries, processes, activities and hazards. You can also dive directly into our four main welding product categories: gloves, glasses, garment and welding product enhancements.

Welding is like sewing, except with fire…. It is the most common method for permanently joining two separate materials or metal parts. The process involves heating metal, adding a filler material that forms a pool of molten material, and then fusing the metal to form a permanent bond.

When the metal cools, a strong bond is formed. In fact, the welded material has greater tensile strength and is tougher than the original metal itself. Through high energy, heat, and pressure a piece of metal is transformed into something brand new.

Welding origins can be traced back to the Bronze Age, well over 3000 years ago. During that time period, it was known as forge welding. This early form of welding consisted of 2 pieces of material being lapped over one another, heated and hammered together until they joined.

Today, electricity has replaced that process, commonly known as ARC Welding. This form of welding was discovered in the 1800s and is now recognized as the most efficient method for joining metal.

Early welding consisted of hammering metal

Welding is responsible for creating over 50% of all the products humankind uses. You can imagine then there are many industries utilizing welding. Here is a look at the many industries employing welders:

Welding occurs in the production of aircraft engine components.

Fixing broken fences, gates and equipment, welding occurs everywhere on a farm.

Automotive trailer and body manufacturing employs many welders.

In 1928, the Carnegie building was the first building to use continuously welded beams. From this point on, welding was here to stay. Since the 1940's, riveting is the main process used.

More than a half million bridges are built across the U.S. That requires many welders keeping these structures intact.

You will definitely spot a welder working in racing fabrication shops. A NASCAR racecar needs hundreds of welds. In fact, roughly 950 man-hours are spent welding and fabricating a race car.

Pressure equipment, piping, heaters, repairs, and equipment upgrades require welding.

61% of all welding jobs are in manufacturing.

Welding of turbines, casing and components takes place across thermal power plants.

Rail cars and rails require welding repairs.

Welding plays an important part in shipbuilding and repair.

The Bureau of Labor Statistics (BLS) reports there are over 400,000 welders, cutters, solderers and brazers. Here are the industries employing the most welders.

| Industry | Employment |

|---|---|

| Fabricated Metal Product Manufacturing | 85,750 |

| Machinery Manufacturing | 50,980 |

| Motor Vehicle Body and Trailer Manufacturing | 20,000 |

| Employment Services | 15,500 |

| Ship and Boat Building | 11,790 |

| Railroad Rolling Stock Manufacturing | 4,260 |

| Electric Power Generation, transmission and Distribution | 1,200 |

| Natural Gas Distribution and Pipelines | 800 |

| Coal Mining | 620 |

The third highest employer of welders is Trailer MFG. MCR Safety gloves, glasses and garments keeps these workers same from hazardous conditions, whether that is cuts, heat or sparks.

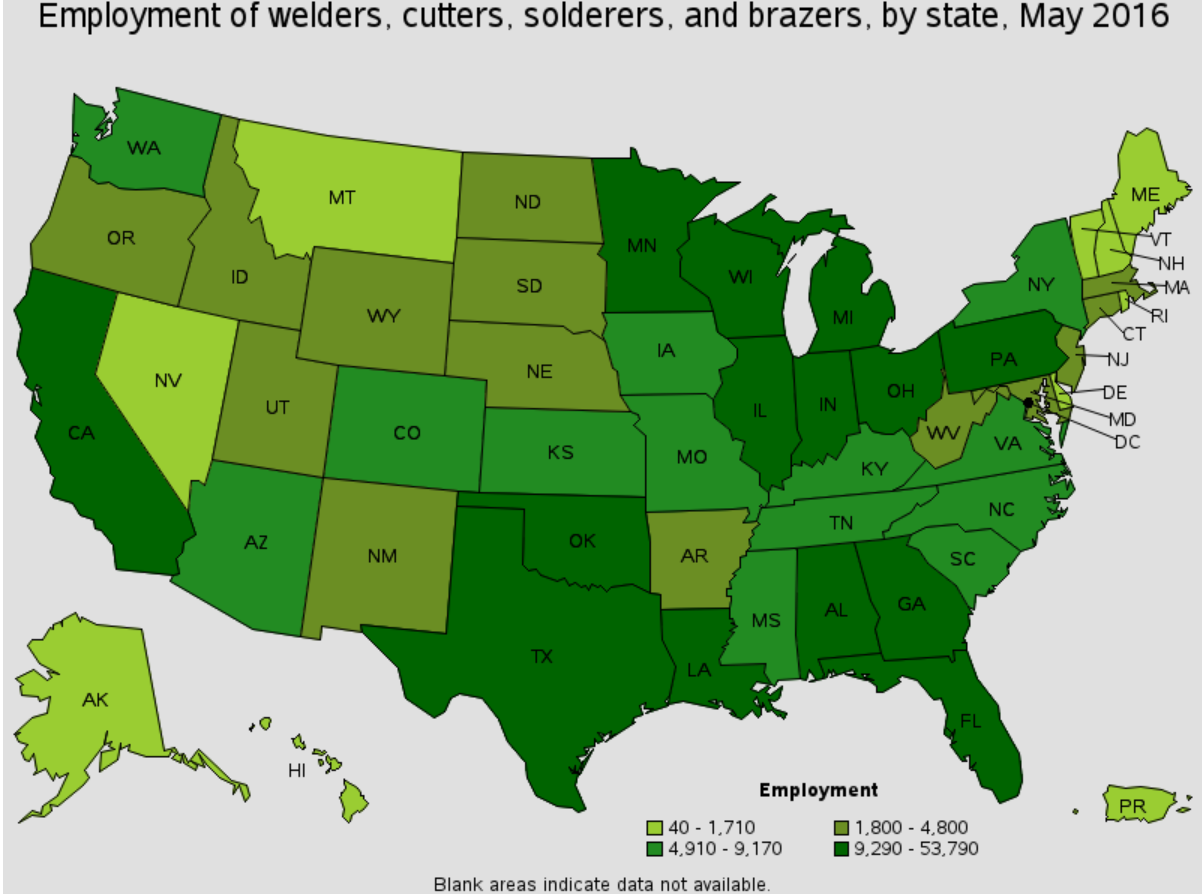

Texas has been called the welding jobs capital, and for good reason. Here are the states employing the most welders.

| State | Employment |

|---|---|

| Texas | 49,510 |

| California | 26,550 |

| Ohio | 17,310 |

| Pennsylvania | 15,320 |

| Wisconsin | 14,250 |

Who is a welder? A welder is someone who build the things most people can’t… Today’s modern ironworkers, metalworkers and welders are responsible for building the very skylines we see every day. Whether one is looking at the NYC skyline or the Golden Gate Bridge, welders have enriched the scenery we view.

Welding is one career always in demand. They can find themselves in any of the industries mentioned above, from an offshore oil rig to a automotive manufacturing plant. Here are the main occupations:

Welders – join metal parts by more than 100 different welding processes.

Cutters – utilize heat to cut and trim metal.

Solderers – join two or more different objects with a melting point below 840 degrees Fahrenheit. Only the added metal is melted.

Brazers – connect thinner metals that higher welding temperatures can damage. Only the added metal is melted.

Uses an electric arc to heat, melt and mix molten deposits of the coated electrode to create a metal bond.

Welding process that uses an electric current between the metal and the welding stick. It utilizes a fixed length electrode, along with an electric power source, to join a variety of different metals. The welding process is ideal for windy and outdoor conditions. Excellent welding process for thick materials.

Uses a combination of electric arc and gas to fuse metal surfaces together. MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding are common for more detailed work, like with welding metal pipes. Both use an inert gas such as Argon or Carbon Dioxide along with a consumable metal rod or wire to complete the weld.

Welder uses a wire welding electrode on a spool that is automatically fed. It's easy to learn but doesn't produce high quality welds.

Welder feeds welding rod to the TIG torch to make a weld. TIG welding allows for the welding of smaller objects. The welds are typically of higher quality than MIG welds.

Precise metal cutting ensures specific shapes, sizes, designs, and thickness levels are achieved. Cutting involves removing unwanted metal material, using a cutting tool. It is an essential process used across manufacturing industries.

The process of removing unwanted material with a cutting tool.

The process of cutting metal with a hot flame.

The challenge across all welding processes are the limitless safety hazards and risks. Here are the most common Welding Hazards:

Protective clothing should always be worn during the welding process. PPE needing worn includes: gloves, leather aprons, faceshields, flame-retardant coveralls and shirts, safety glasses, and leggings.

Welders hold a lot of sharp metal. It only makes sense to wear some cut-resistant welding gloves.

Dry gloves should always be worn to protect against electric shock.

Eye injuries from projectiles, hot slag, metal chips, hot electrodes and bright lights are an everyday concern.

The intense heat and sparks produced when welding can potentially cause fires or explosions. Welding should only take place in areas free of combustible materials.

Welding fumes contain harmful complex metal compounds.

Intense heat, needed to melt metal, is produced by an electric arc.

Fingers and hands can easily be burnt due to hot metal or molten materials.

Small pools of molten metal are formed at the weld. Non-FR clothing should never be worn.

Welding and cutting creates a lot of flying sparks that can burn eyes.

Metal flying during the welding process.

Burns to eyes are a top eye injury recorded each year. The intense light associated with arc welding can cause damage to the retina of the eye.

Personal Protective Equipment (PPE) should always be worn when welding. At MCR Safety, our goal is ensuring welders make it home in one piece. We proudly manufacture welding gear, ranging from welding eyewear, welding gloves to welding garments.

Since we manufacture our welding products in our owned manufacturing facilities, we know a little something about the process and what’s needed in keeping welders protected. Below, you will find some insightful welding information and links to all the welding gear we offer.

Let us get you into the right welding and safety gear you need. Just click on the various links below and we will show you all the options we offer.

Learn more about the technologies that fuel the fire behind our industry leading protective gear!

Like fusing metal? Who doesn't right!? Check out our latest welding resources from our blog. You might just learn something new to keep you safe while you do your thing.