In our "ABCs of Leather Gloves blog", we break down leather gloves into the simplest parts of understanding. However, as with all things, the subject matter can go as deep as you want to go. Many times, people will shrug off diving into a subject matter and will leave it to the specialists to work out the more profound points. Well, MCR Safety is the specialist when it comes to leather work gloves, which means we delve deep into the subject almost every day. We also encourage you to go a little deeper into the subject if you're the one purchasing or wearing the gloves. There are numerous factors that impact leather glove costs, performance, and feel.

On this page, we cover everything you need to know about leather gloves in one spot. From different leather hides, different cuts, and different thumbs, many variables impact the final leather glove you purchase.

Consider this your online guide to becoming a well-informed purchaser of leather work gloves.

Leather hides are the outer coverings of a grown animal. We use the word "hide" to distinguish the skin of larger animals, such as the cow, and “skin” to refer to smaller animals. Since leather is a by-product of the meat industry, cowhide is the most abundantly available hide. However, four species of animals are most commonly used in glove making: 65% from cows, 15% from sheep, 11% pigs, and 9% from goats. The characteristics of each differ.

As a general rule, the bigger the animal, the thicker the leather hide, which is the case with buffalo. Buffalo leather gloves share many of the same characteristics as cowhide, yet with some additional enhancements. One of those enhancements is most definitely the cost, though there are a handful of other benefits as well.

Here is a quick rundown of the benefits of buffalo leather:

Downsides:

Cowide is leather produced from the hides of full-grown cows. It is the most popular leather because of its availability and can be made with either a smooth or rough finish.

Here is a quick rundown of the benefits of grain cowhide leather:

Downsides:

It is the most comfortable, flexible, and softest leather hide MCR Safety utilizes in its leather glove lineup. We often refer to it as the most luxurious leather glove available. Just be aware that deerskin doesn’t come from commercially raised sources, as other leathers do. They come mostly from wild game and require a more complex tanning procedure. This means it is one of the more expensive leather options on the market.

Here is a quick rundown of the benefits of deerskin leather:

Are you looking for ultra-thin leather gloves that allow you to handle delicate parts and materials, while offering strength and protection at the same time? Independent tests have proven goatskin leather to be one of the strongest hides available. The dense fiber structure and tensile strength of goatskin enables gloves made with this hide to hold up under the toughest working conditions.

When you wear goatskin, you’ll love the ultra-thin feel, along with the natural lanolin that softens one’s skin. MCR Safety’s unlined goatskin work gloves are so thin that they are often mentioned as the best skin-tight leather gloves you’ll find. Plus, these gloves come in at a mid-range price point and are not as expensive as elkskin or deerskin leather gloves.

Known to many as a thin leather glove, here is a quick rundown of the benefits of goatskin leather:

Downsides:

Like its distant cousin, deerskin, elkskin leather work gloves are extremely soft and comfortable to wear. Plus, because the hide is thicker than deerskin, it insulates better. The hide’s added thickness makes elkskin leather work gloves more durable, too. One of our most requested elkskin gloves is a foam-lined option. Both are classified as welding gloves; however, they are excellent gloves for use during winter months.

Tough, yet a suppler leather hide that dries out soft and not stiff. Like deerskin gloves, be aware that elkskin leather work gloves don’t come from commercially-raised sources. Elskin leather work gloves are one of the more expensive leather gloves on the market.

Are you looking for an economical leather work glove? Pigskin gloves may be just what you'll want to wear. Don’t let their low-cost fool you into thinking they’re low-quality. MCR Safety’s pigskin leather gloves are multi-faceted, offering exceptional durability, breathability, and water-resistance. If you look at the image above, you can see the porous texture; this texture makes pigskin the most breathable leather glove you’ll find. It is this same texture characteristic that also keeps pigskin gloves flexible after frequent contact with water. For example, those who work in maintenance and need a glove that holds up to moisture will find pigskin driver gloves don’t stiffen up after contact with moisture and maintain their top-quality performance for more extended periods.

Here is a quick rundown of the benefits of pigskin leather:

Downsides:

Most of our Mechanics style gloves and Tactile leather gloves feature synthetic leather. So, they might not be called official leather drivers, but they are extremely comfortable. The four styles shown above feature a super stretch material in the knuckle region, offering wearers a higher degree of dexterity than standard leather driver gloves.

What is synthetic leather?The first substitute for natural leather started in the 19th century with the development of Nitrocellulose and collodion. In the 20th century, DuPont™ patented Fabrikoid, which was primarily used in upholstery and book bindings. Today, there are three fundamental kinds of synthetic leather fabrics: polyurethane (PU) leather, polyvinyl chloride (PVC) leather, and microfiber leather. Each of these is treated to resemble and feel like real leather.

Since the early to mid-2000s’, MCR Safety has been offering synthetic leather work gloves. With increased pressure put on the overall leather supply chain in 2008, mostly due to numerous tannery closures, MCR Safety decided it was necessary to offer our customers additional synthetic leather work glove options. Artificial leather has numerous advantages over real leather. Some of the benefits of synthetic leather include:

Keep in mind: synthetic leather is not recommended for welding, where heat and open flames are present.

MCR Safety offers a wide assortment of synthetic leather styles:

When manufacturing leather work gloves, thick animal hides are split into multiple layers of leather, ultimately creating two distinct types of texture. More on this in a moment. Leather can be made from all types of hides and skin, which means you should pay attention to the details when purchasing leather gloves. Depending on where hides are split, the durability, dexterity, and overall longevity of a leather glove will be impacted. With that said, let's get back to texture; have you noticed that different leathers have different textures?

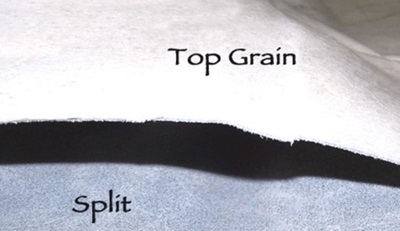

Different textures occur as a result of the animal hide used, what part of the animal the leather came from, and which side of the leather hide was processed. We'll cover this point more in each leather work glove page. Generally speaking, when a thick piece of leather is split into two thinner sections, the top part will have grain ('top grain'), and the bottom portion will be suede on both sides. The bottom piece is the split. Here is a breakdown on both types:

The the smooth, external top layer of the hide. Grain leathers are not buffed or sanded, which means they have a more appealing appearance. They also offer the following advantages:

The rougher, inner side of the leather that remains after the outer layer is removed. Because of its coarse hide and dense fiber structure, split leather provides users with the best heat-, abrasion-, and puncture-resistance. Another beautiful thing about split leather is that it is less expensive and offers more significant gripping properties in oily conditions. Split leather holds up better to absorption, due to the thicker leather.

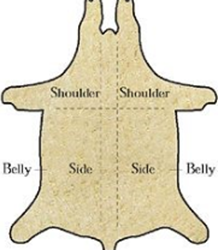

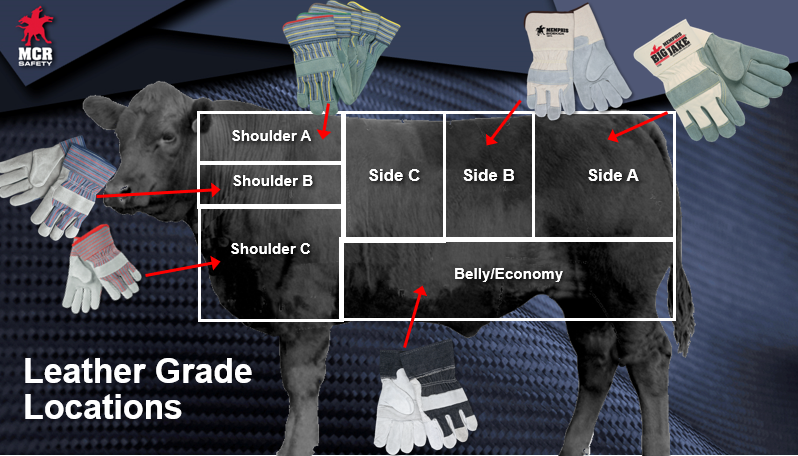

Split leather is divided into three categories depending on where on the animal it comes from:

The most economical of the three categories, it has the least consistency of texture and appearance

A more economical choice, its lower price point comes from the fact that it’s a less durable leather.

This part of the leather is the most durable and provides the best protection.

Once the hides are split, separated, and the leather grades are distinguished, two types of leather work gloves emerge: Leather Drivers Gloves and Leather Palm Work Gloves. Leather drivers mostly use the grain side, with some exceptions. Split leather is utilized to create full split-grain drivers, as well as combinations of a grain leather palm with a split back. Leather palm gloves use the split side of the hide and are comprised mostly of cowhide. We break down each type on separate pages across our leather work gloves section.

Like all personal protective equipment, leather work gloves will wear out over time and need to be replaced. However, a leather's grade directly impacts the overall glove's longevity. By knowing the differences in leather grading, you'll avoid unnecessary spending and will be protected with better quality PPE. As we highlighted above, hides are split up into either grain or split leather and where the leather hide is derived from affects the grade quality. An essential component of shopping for leather work gloves is knowing the location of where on the animal the leather was cut. Whether the leather comes from the animal's side or its shoulder or the belly strongly impacts the overall grading and cost of leather gloves.

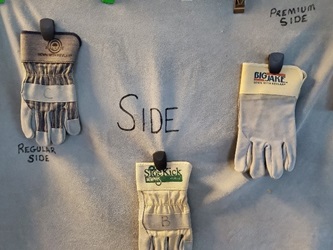

Grade “A” leather typically has very few exterior flaws or scar marks on the hide. The side of the leather hide, specifically in the rear, provides the highest density of fibers, making it a premium grade product. As the grade moves down to B, C, and D, it begins showing more exterior flaws, including a more nappy texture and appearance. Keep in mind that imperfections can occur all over a leather hide. These flaws may exist from scratches that happened to the animal, such as from thorns or contact with other animals. As the grade drops, one should anticipate less durability from the leather over a shorter period. Here is a rundown of the different grades:

As you can see in the above image, we have premium side leather options sewn with DuPont™ Kevlar™, like our Big Jake®. We also offer economy versions like our 1200 series and mid-range options like our 1400 series. At MCR Safety, we offer many different leather glove options with varying levels of quality. It is an important buying consideration when choosing to partner with MCR Safety. No matter the grade or thickness of leather you need, we have you covered.

In addition to the location of where the hides come from, numerous other conditions can cause the hide to drop in quality. Here are some:

Over the years, MCR Safety has built a reputation for consistently supplying quality leather gloves. We take great pride in hearing this from our customers, as we highly stress leather grading across all our operations. For distributors, it is important to partner with a leather glove company that is known for offering consistent quality levels over a lengthy timeframe, not just over a couple of orders.

We visited a boat manufacturing company that uses our products some years ago through our 360° protection program. They asked us to come out due to the fact that employees were only able to use a pair of leather drivers for a day at most before the glove was destroyed, typically about halfway into their shift. It turns out they were wearing a lower grade leather glove, sewn with only polyester. Employees were working around machinery that was wearing down the low-grade leather.

Yes, the customer thought he was saving money with a less expensive leather glove, but when he accounted for the increased number of gloves he needed to buy to keep his workers’ hands protected, he realized it was not cost-effective. After examining the working conditions in this company, we put this customer into one of our highest grade leather drivers, which is sewn with DuPont™ Kevlar®. Costs began to start lowering within a short time, and employees were no longer exposed to dangerous machinery with ripped up gloves.

By now, you are probably aware that leather grain gloves are easily 2-3 times more expensive than leather palm work gloves. There are a number of reasons for this cost difference. Aside from the location of where the hide originates, other factors that affect cost include:

So, what makes a nice pair of quality work gloves? Grade of leather, the location from the hide, and thickness are all critical factors in determining the longevity, abrasion resistance, and overall glove cost. In addition to these, there is a multitude of intricate parts to a leather glove. We discuss each of these more in-depth below. Every one of these will impact the longevity, feel, and performance of leather work gloves. So, when you see a leather work glove that is coming in at 20-30% less than another glove, you might want to start examining each one of these areas.

.png?mw=300&hash=988B5593F94C5C8017A547CAF82807A1)

Every leather glove has a pattern and overall design, which is the cut. Cut style is the third most crucial component that separates one leather glove from another, after splitting and grading of leather has occurred. The leather glove pattern will determine the overall dexterity and comfort a user will experience when wearing. Here are the two most common cut styles:

A glove that is sewn with a one-piece leather palm. There are no seams at the base of the fingers. Instead, the seams run along with the fingers. This glove style is traditionally made with a straight thumb. There is less labor involved in making a clute cut design, which means it can be offered at a lower cost, making clute cut gloves an economical choice.

The most common pattern found in constructing leather work gloves. Gunn cut gloves feature a seamless back, along with seams away from the palm at the base of the two middle fingers. They are designed to lessen the strain put on the glove’s materials, providing more extended wear and a higher degree of comfort. Unlike clute cut leather gloves, Gunn cut leather work gloves are designed for heavy-duty applications.

Leather stitching is a significant factor in a glove's longevity and cost. Most complaints you hear from users revolve around a glove breaking apart, especially in the seams. This problem often has more to do with the stitching than the leather quality itself.

When a leather glove is stitched with polyester, the cost comes down, but so does the glove's ability to withstand heavy-duty work. However, when the stitching is sewn with strong DuPont™ Kevlar®, you’ll find a glove that lasts a long time and can take a greater level of abuse at work.

Here are the most common types of thread used in stitching gloves:

How about a leather work glove that is double-stitched with DuPont™ Kevlar®? Our utility leather work gloves are all double-stitched, doubling the strength!

If you continue to have trouble with leather gloves breaking down on you, the answer may lie in the stitching. After a couple of long, hard days of work, your less expensive stitching will start to come apart, it's just how it goes. When you want a pair of gloves to last an entire week, you choose one made with advanced, high-performance fibers like DuPont® Kevlar™. When you want them to last even longer, you choose a glove that has been double-stitched!

Gloves are worn to protect, and when they no longer cover the hands they are supposed to be protecting, they become a hazard themselves! Stitching is a vital buying factor, so be sure to note how gloves are stitched and what material is used for the sewing before you buy.

When considering which leather glove to wear, it is important to understand all the factors that affect comfort, performance, and price. You might not be aware of this, but the thumb style of leather glove impacts all three. One of three thumb styles is generally found on leather gloves. Here is a breakdown of each:

The thumb lies straight with the index finger when not in use. Straight thumbs are the most economically priced option since a smaller amount of material is required.

An inset thumb is sewn in as a seperate piece and is shown in the image below. It is reinforced with extra stitching and provides greater comfort and dexterity over gloves manufactured with straight thumbs.

An angled thumb is sewn out to the side and doesn't include seams, making it the most durable, longest-wearing, and comfortable thumb style available in our line. This thumb style mirrors the natural shape of a person's hand and allows the thumb to move freely. Since it's cut from the same piece of leather used to create the palm, a wing thumb requires more leather, making it the most expensive option.

You can look at the three gloves shown below and know a glove's back impacts cost and performance. Knowing how you will be using your glove and the features you need to stay safe on the job should affect your determination of which back material is best for you. If you're working around heat, you're going to want a full leather back glove to protect your hands. If you don't require quite that level of heat protection and you want a glove that offers some breathability, a standard canvas back might be a perfect choice.

Backs found on leather gloves:

This material provides breathability and comes in at a lower cost than full leather backs.

When protection is needed up the knuckles, a ¾ back is a good option, and it still allows for some breathability.

This option covers the entire hand for 360° protection. The full leather back is used when additional protection is needed over the whole back of the hand.

Although it provides limited hazard protection, it provides the greatest level of breathability due to openings in the material.

We may rank these towards the end of the buying stage for leather gloves, but they still deserve attention. If you don't pay attention to these features, you may be extremely disappointed if you were needing extra protection or wanting to keep debris out.

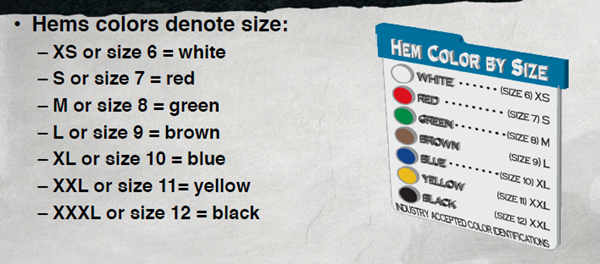

The most economical hem, often identifies a glove's size.

A cuffed hem that is created by "rolling", or folding the leather onto itself. This style of cuff provides extra protection and durability when putting on the glove.

It is almost impossible to find two people exactly alike and made with the same hand size. We're all unique, especially when it comes to hand size. To find your correct size, measure around your dominant hand below the knuckles, without including the thumb. When looking at the sizing chart, pick the size based on the measurements shown. A correct size glove will adapt itself to the exact shape of one’s hand.

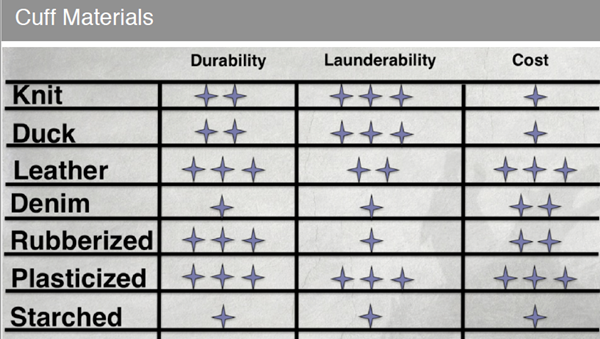

Cuffs are the essential ingredient in leather work gloves and play an important role in certain applications. When you are faced with particles that impact your wrist area, extending the cuff out is the quickest way to add protection.

A glove's cuff is the additional material added onto the glove, providing extra protection further up the wearer's arm. Here are some of the cuff styles found on MCR Safety’s leather work gloves:

Covers the wearer a few inches past the wrist to provide general protection. Safety cuffs generally measure 2.5-inches in length, but that length may range somewhat. Safety cuffs are designed to allow for quick donning and doffing of gloves.

The longest cuff available, starting at 4.5-inches and longer, provides extra forearm protection against hazards like heat and rough surfaces.

Provides a snug fit to keep out wind, dirt, and debris, while protecting the user’s wrist. It also seals in the warmth and keeps the glove in place.

Glove material extends to the wrist, and the knit cuffs are easy to get on and off.

Rubber material is sandwiched between two layers of fabric.

An economical, single-piece fabric.

A band of material is sewn to the glove for light-duty wrist protection.

Cinch the cuff tightly to your wrist.

We only list liners last on this page because they typically provide users with a more specialized level of protection, either for added comfort or added warmth. They're important, but only if you require a lining. All the others discussed above apply to all leather work gloves.

Liners are highlighted across our leather gloves sections, most importantly on our Winter Lined Leather Work Gloves section. We say most important only because liners are the essential component that keeps one's hands warm during cold winter months.

Linings are the materials located inside leather gloves that serve a multitude of purposes. First, a delicate fleece lining means all-day comfort for those who use their hands a lot. This fleece comfort can also provide protection and cushion from the tools and objects used in many industries. Second, and often forgotten about, is the assistance a lining can offer with donning and doffing gloves. Third, and perhaps most importantly, a lining prevents chafing.

Here is a recap of the benefits that general-purpose linings offer users:

A jersey fleece-lined leather glove is one of the most common lined leather work gloves you’ll find in our product lineup. This general-purpose liner is lightweight and provides natural wicking, keeping moisture off the skin. However, one downside to general-purpose liners is that they offer zero cut-protection. MCR Safety does offer over 15 total leather glove styles with cut protection. Check them out here.

To summarize, you'll find cut-resistant liners for cut protection, jersey liners for moderate heat protection, and, of course, winter linings for the cold. Here is a description of each type of lining: