We've spent a lot of time over the past couple of years highlighting industries where MCR Safety products are used. What about MCR Safety, the company? Below, we highlight the many areas of PPE where MCR Safety directly manufactures products to keep workers safe. MCR Safety has 40 years of experience as a leader in the field of personal protective equipment (PPE). Our product lineup includes gloves, glasses, and garments that are made from the highest quality materials available to ensure maximum safety, comfort, and style.

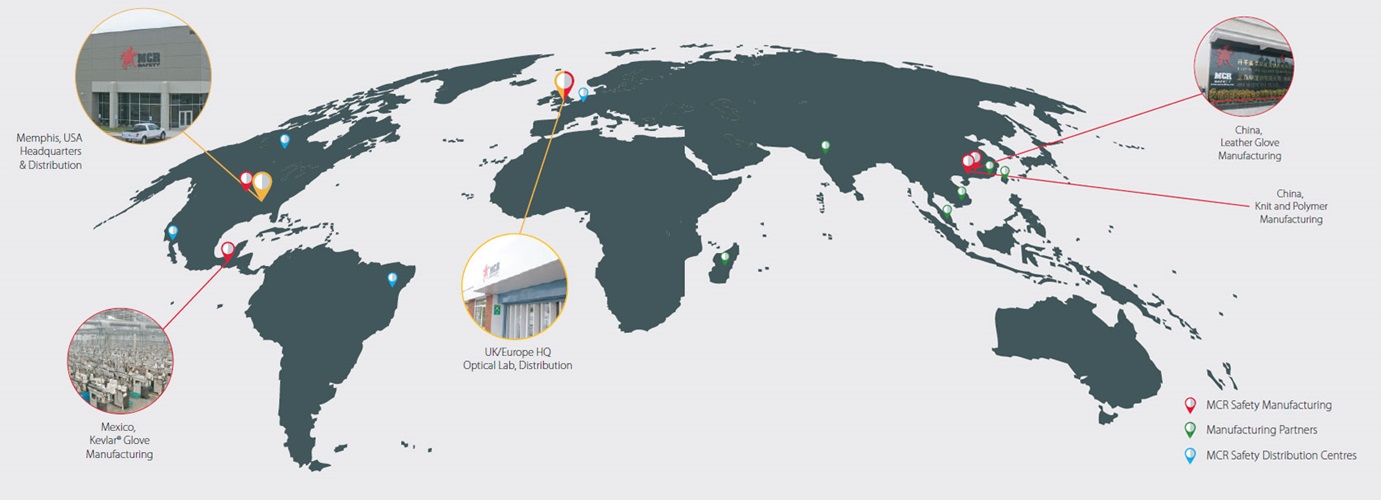

MCR Safety distinguishes itself as a global manufacturer. We employ over 1,600 people internationally, with approximately 300 people working domestically at our corporate headquarters and distribution centers. We're one of the largest privately held PPE companies in the U.S., with global operations spanning six continents.

As we highlight on the opening leather page, leather goods are one of the oldest known commodities made. MCR Safety has been supplying leather gloves to multiple industries since the 1970s. Initially operating as Memphis Glove, today, companies recognize us only as MCR Safety. Since 1988, MCR Safety has been manufacturing our own high-quality, cut-n-sew leather work gloves that protect the hands of workers across multiple industries. Today, with the recent expansion of NXG Intelligent Manufacturing , one of our most distinguishing qualities is that we directly manufacture over 2/3 of all gloves we offer!

Our knowledge as a manufacturer helps us evaluate leather sources of supply to assure reliable quality and competitive pricing. With leather work gloves, this is especially important as the market is influenced by demand from industries such as automotive, furniture, sports, and apparel. Other factors, such as the cost to raise beef cattle, grazing conditions, drought, and people’s overall consumption of beef, also affect the price of hides. With our knowledge of production costs, we have been able to better evaluate other leather glove vendors for sourcing many of our economy leather glove work styles.

So, how do you make leather work gloves? There are three stages to manufacturing leather, with a multitude of sub-stages involved during the process. Here is a quick look into the world of leather manufacturing.

The steps outlined below involve enhancing the physical properties of the leather.

What we’ve covered above is only the necessary stages involved with manufacturing leather. Now begins the leather glove manufacturing stage. Glove manufacturing requires great sewing skills and is extremely labor-intensive.

Each sewer has a specific sewing operation, adding one component in an assembly process until the glove is completely constructed inside out.

In 2019, MCR Safety opened a brand-new manufacturing facility incorporating the most advanced manufacturing technologies. Our new manufacturing facility produces our highest quality products with 21st-century manufacturing efficiencies and environmentally-friendly production. This facility is covered more in-depth on our NXG page.

MCR Safety proudly manufactures gloves and sleeves using Kevlar® fiber. In fact, we are the only licensed manufacturer that spins our Kevlar® yarn, as shown in the image above.

Be sure to check out more information about Aramid fibers from our "Safety to the MAX" blog.

MCR Safety became the exclusive manufacturer for Summit Breeze® FR technology in many of its garments. Workers requiring flame-resistance will be supported by the coolest FR products on the market. You can view more about this technology on our Summit Breeze® Technology page .

We also directly manufacture welding apparel, t-shirts, and vests at our Mexico operations.

Last but not least, MCR Safety manufactures safety glasses in directly-owned operating facilities. In 2019, MCR Safety upgraded its eyewear manufacturing facility to produce the first-ever UV-AF eyewear incorporating highly efficient, environmentally-friendly product equipment.

Consistent quality was, and remains, the foundation for MCR Safety. Our logo, which incorporates Max, represents the three core products of MCR Manufacturing as each head represents one of the pillars of products that make up MCR Safety. Max means protection.