"It will never happen to me"

Well, you know what happened to the Titanic.....

A similar story takes place every year for metal fabrication workers who say to themselves an injury will never happen to me. Do not fret; we cover the hazards found across all four metal fabrication industries and make some helpful safety gear recommendations below.

Ever since meteors struck earth years ago, leaving iron ore deposits across the surface, mankind was destined for great metal objects. The ancients Greeks believed in Hephaestus, responsible for all Metalworking, who took iron ore and created great metal objects. As Aeschylus says, the "The will was of Zeus, the hand of Hephaestus". The Romans believed in Vulcan, responsible for all metalworking and the forge.

Well, we at MCR Safety don’t partake in ancient metalworking beliefs or practices; however, we’re heavily engaged in protecting the hands of today’s metalworkers. After all, it’s what we do, We Protect People! Hephaestus or Vulcan, you might want to consider our Diamond Dyneema gloves, which are 15X stronger than steel metal.

Vulcan

Hephaestus

Look around you, it is evident man's hands are responsible for creating a world filled with metal. From weapons, to automobiles, to great buildings like the Eiffel tower, all the way to copper material powering our smartphones, there is metal present.

With so many hand's creating metal objects, not just the hands of Hephaestus or Vulcan, there are those responsible for protecting the metalworkers themselves. This is where MCR Safety enters the picture, protecting over 1.4 million workers in the metal fabrication industry.

Eiffel Tower

Eiffel Tower

Metalworking essentially involves working with metal to create individual parts. It typically encompasses one of three categories: Forming, Cutting, and Joining. As mentioned above, this process goes back to Greece and antiquity, when great metalsmiths created bronze weaponry. In our modern world, there are four primary Metal Fabrication industries where metalworking is present: Forging/Stamping, Machine Shops, Sheet Metal Works, and Structural Metal.

| Metal Fabrication Sub-Industry | Recordable Injury Cases |

|---|---|

| Forging and stamping | 6 |

| Prefabricated metal building and component manufacturing | 6 |

| Custom roll forming | 5.6 |

| Sheet metal work manufacturing | 5.6 |

| Fabricated structural metal manufacturing | 5.4 |

The average recordable injury case for metal fabrication is 4.4 for every 100 workers. With over 26% more injuries occurring in the forging and stamping industry, you know we are going to specialize in PPE for these workers. Across the metal fabrication industries, you will find Metalworkers, Machinists, Structural Steel Fabricators, Machine tool cutting operators, and welders. The common theme for all these workers is that they face hazardous working conditions.

Here are some of the activities these workers perform:

Regardless of the metalworking performed, there are similar hazards faced requiring personal protective equipment (PPE). With that said, each worker faces some unique hazards pertinent to their specific task. For example, fabricated structural metalworkers are mostly welding, whereas machinists working in machine shops are highly concerned with flying metal objects.

Here are some of the other top occupations found in the Metal Fabrication industry:

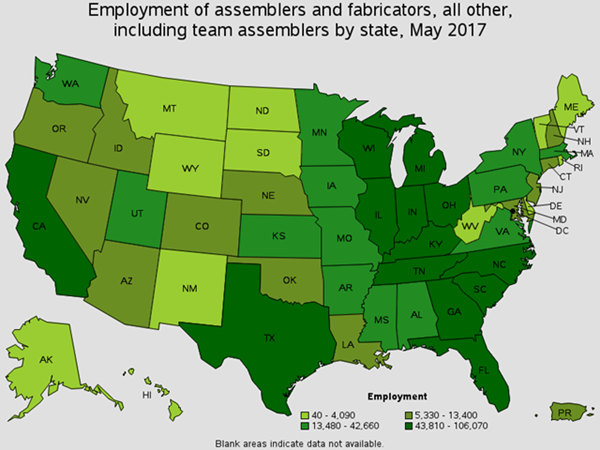

Click an occupation to expand and learn more information.Assemble finished products, along with parts and pieces that go into them. There are over 1.8 million people employed across the US in an assembly and fabrication position. You will find these workers assembling bolts, using many different types of tools, and moving heavy parts. There are around 130,000 of these workers in Metal Fabrication.

Operate machines to taper, shape and form metal. Around 17,000 workers fall into this occupation. You will find these workers removing dies, forging hammers and moving metalwork pieces. Common Job titles for this position are Forger, Blacksmith, Hammer Operator, and Forge Press Operator.

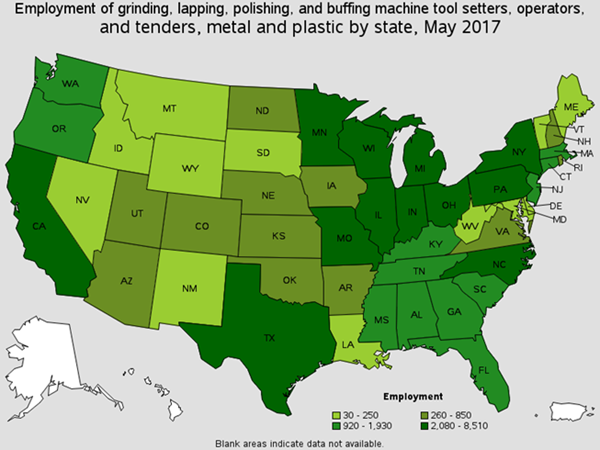

Operate grinding tools that remove excess metal material or burrs. 26,000 of these workers are in Metal Fabrication. You will find these workers sharpening edges and corners, along with polishing metal. Common Job titles for this position are Deburrer, Finisher, Grinder, and Grinding Operator.

Operate lathe and turning machines to turn, bore, thread and form metal, such as wire, rod, or bar stock. There are roughly 14,000 of these workers. You will find them replacing worn tools, sharpening dull cutting tools and using cutter-grinding machines. Common Job titles for this position are Screw Machine Operator, Turn Operator, and Lathe Setup Person.

Operate cutting and forming machines. Roughly, 6% of the workforce falls into this occupation. There are roughly 107,000 of these workers in the Metal Fabrication industry. Common Job titles for this position are CNC Machine setter, CNC machinist, and CNC Operator. Exposure to hazardous equipment is always a concern for this worker.

Manually move materials to perform general labor. . Around 47,000 of these workers are in the Metal Fabrication industry. You will find these individuals loading docks and materials to production areas.

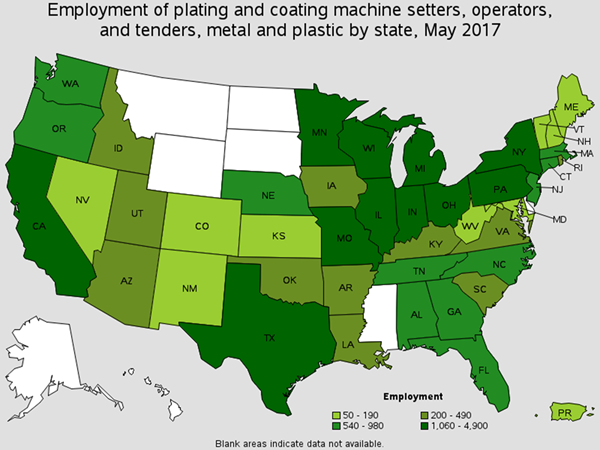

Operate machines to coat metal or plastic products to protect or decorate surfaces, with chromium, zinc, copper, cadmium, or nickel. There are roughly 22,000 of these workers in Metal Fabrication. You will find them immersing metalwork pieces in coating solutions. Common job titles for this position are Anodizer, Chrome Plater, Plater, and Coater Operator.

Fabricate, position, align and fit parts of structural metal products. There are a little over 36,000 of these workers in Metal Fabrication, with over 25,000 of these in Structural Metal. You will find them positioning welding parts and moving parts into position. Common Job titles for this position are Fabricator, Mill Beam Fitter, Structural Steel Fitter and Layout Man.

In simplifying your PPE search, we have assembled unique industry education pages for each Metal Fabrication sub-industry. As always, our goal is educating workers on the specific hazards they face and providing many useful resources. Let us help you find the best safety gear for the metalworking hazards you face!

We Protect People!

See distinct sub-industries within metalworking and find recommended PPE to keep work safe.

Find the appropriate PPE for specific hazards with a simple easy to follow guide.

Learn more about MCR Safety product features that protect against these common hazards.

Click "Learn More" to find info on protecting yourself against these hazards and find the right gear for the job.

Metal workers are exposed to flying fragments, particles and projectiles. When metal chipping, you will need goggles and face shields with 6X greater fog resistance.

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.