The impact material found on MCR Safety's work gloves is made with a flexible medium that moves with your hand and doesn't impede motion, like our PD3950 glove. MCR Safety impact gloves are designed to keep your hands guarded against dangerous objects that can cause lifelong injuries.

Below, you will find all the impact glove styles that MCR Safety manufactures. We first highlight our different brands and then break down our most requested impact gloves.

In layman's terms, impact gloves are engineered with shock-absorbing technology that protects the back-of-hands. Thermoplastic rubber (TPR) and D3O® are two of the most common impact-resistant materials utilized on MCR Safety work gloves. By adding exterior padding to the back of a work glove, the additional material absorbs and dissipates energy. Also, you're equipped with a pair of gloves that feature many advanced qualities. Here are some worth noting:

And, as you'll discover below, we even offer glove styles with padded palms that provide front-of-hand protection, too.

Every day, over 160,000 million Americans head off to work, finding employment across numerous industries. Those who work in dangerous environments, such as mining, oil and gas, and construction, turn to personal protective equipment (PPE) to keep them safe from workplace hazards. Impact gloves are designed for some of the harshest job conditions workers face.

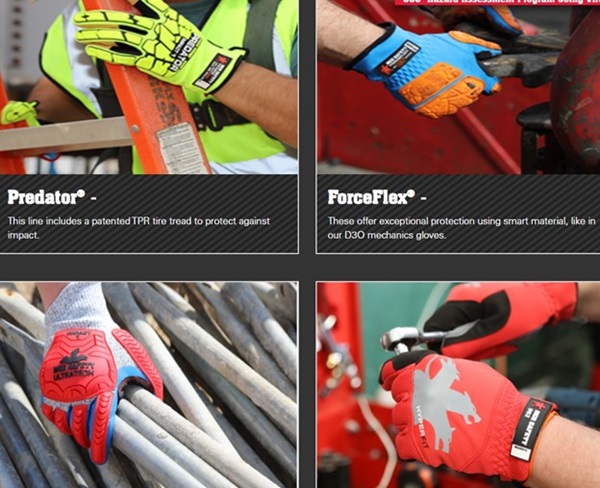

Take a look at the different impact glove brands MCR Safety supplies:

Everyone deserves to wear quality PPE. All of our impact glove brands aim to be just that: equipment that protects people and provides solutions that keep one's hands unaffected by the numerous hazards workers encounter. Let's now highlight the different types of impact gloves that fall under each brand we offer.

![]()

Whenever someone is looking for the best-rated personal protective equipment (PPE), they want protection with high ANSI performance levels. The best-rated safety gloves with the highest impact protection we have to offer feature an ANSI level 2 performance rating for impact protection. The following glove styles are engineered to meet level 2 protection standards:

Anyone unfamiliar with impact level ratings and the new scoring system, be sure to read Everything You Need to Know About the New ANSI ISEA 138 Impact Protection Standard. This article covers all the technical elements, from why the protection standard was developed to measuring its most essential performance areas.

If you overlooked the sorting tool on the primary Impact Protection page, we've included it below. It's important to keep in mind that glove costs increase as more advanced materials are required to improve impact performance scores. Some workers may only need impact level 1 or even simply bump protection, which is why we've included the sorting tool a second time here for you to review.

As we highlight on our About Leather page, leather has been utilized for thousands of years to protect people. So, it makes sense that MCR Safety, which has been supplying leather gloves since the 70s, would have leather impact gloves, right?

Not only have we introduced these types of gloves, but we also now have over ten different variations. From welding options to cut-resistant styles, we offer impact protection for workers every day. Here are some of our most popular versions:

36136KDP, PD2910, MU3634K, PD2903, PD2907

Our most recent addition to our leather glove lineup is the PD43612, which was awarded the DuPont™ Kevlar® Innovation Award as its product of the year. The Predator®-style glove is equipped with an A9 cut-resistant shell, providing users with one of our most advanced gloves ever designed.

When you examine the world of workplace accidents, cut injuries are one of the top hand injuries reported. As we point out on our Cut Protection page, cut injuries make up 8.1 incidents for every 10,000 workers. In 2015, more than 106,400 cut and puncture injuries occurred. To help protect against these types of injuries, it only makes sense to feature impact options with cut-resistant shells. We highlighted the PD46312; however, there are now numerous styles that incorporate cut-resistant material. Here are some others to consider:

Keep in mind; the PD4900 is one of only two styles that we offer that provide Penta protection, which means the glove is effective across five ANSI performance categories. For the PD43612, it positively tests for IMPACT 1, Puncture 5, Abrasion 4, Cut A9, and Contact Heat 3. When we say we protect people, we mean it!

Like the PD43612, this highly advanced glove provides abrasion-, cut-, impact-, heat-, and puncture-resistant protection. We recommend you check out our most recent video that highlights both our cut and impact-resistant gloves.

When you find yourself working in wet environments, you need protection that prevents liquid from penetrating the glove's material. We have numerous waterproof work gloves within our chemical-resistant and disposable glove lineups. However, those made with impact protection are relatively new. We carry two impact gloves with easily recognizable colors, orange and yellow. Both are designed to protect a worker's back-of-hand and keep liquids at bay.

N2659HVL Impact Level 2 and ANSI A4 Cut-Resistance

N2658HVO Impact Level 1

In addition to the above gloves, our FF2932 and MO200 feature an internal waterproof bladder that keeps liquids away from one's hands.

Padded work gloves are an excellent choice for anyone handling heavy objects or operating power tools all day long. Why? These gloves are reinforced in critical areas and are designed to provide maximum durability and all-day comfort. For those who operate power tools or handle heavy objects on a daily basis, you will be surprised at how much of a difference palm padding makes.

Many of our impact gloves are designed with impact-resistant palms to accompany the back-of-hand padding, ensuring 360° protection. Here are some of the gloves we offer with enhanced padding in the palms and the back-of-hand.

Our 36136KDP are double padded!

Crush hazards that can bang up a worker's back-of-hand are present on just about every job site. However, Mother Nature poses concerns during winter months that are even scarier. Strong winds and arctic temperatures are safety hazards that can cause frostbite injuries that affect victims for a lifetime.

One of our most recent additions to the Predator® brand, PD3954, is insulated and provides cut and impact protection

If you must venture out into the cold for work and need to keep your back-of-hand protected, cover your hands with one of these gloves.

Sure, an impact glove can help protect hands against a blow from another object. However, the main question for many is: Can this work glove still function around the contemporary world's electronic wonders?

Touchscreen capability has become a vital buying decision for customers in recent years. Some of our newer glove styles, like the PD3952 and PD3954, allow one to use a handheld touchscreen device while maintaining back-of-hand protection.

Anyone looking to utilize their touchscreen phone or machinery easily, without removing their gloves, should consider wearing our touchscreen gloves with impact protection.

When crude working hands meet crude oil, you need to be wearing the proper protection. Be sure to give the above options a try next time you're heading out to work in the oilfields.

There is a multitude of different features users look for in impact-absorbing gloves. We've put a spotlight on the most requested features users inquire about every day. Here are some other quick links to various styles:

MCR Safety Protects Both the Back and Front of Hands with high-performance gloves!

For tough jobs, you need tough gloves! Wearing MCR Safety impact gloves ensures you are wearing the most advanced hand protection available on the market today.