Across these pages is an enormous list of typical questions asked, along with some definitions of key terms. As this type of PPE rapidly evolves, we will continue adding definitions across these pages.

It is almost impossible to find two people exactly alike and made with the same hand size. We're all unique, especially when it comes to hand size. To find your correct size, measure around your dominant hand below the knuckles, without including the thumb. When looking at the sizing chart, pick the size based on the measurements shown. A correct size glove will adapt itself to the exact shape of one's hand.

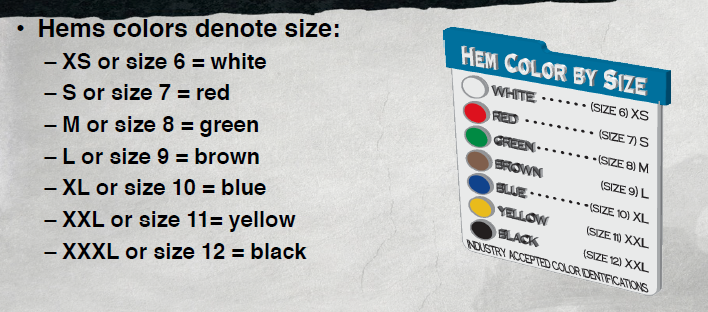

MCR Safety Hem Colors for leather work gloves

In short, yes. How to clean leather work gloves is covered in-depth here.

Wet forming leather gloves is one way to break in leather gloves. Sometimes just wearing them for a bit of time can help them break in and begin to form to your hand.

Yes, if additional components have been added, like with our MO100 and MO200 leather gloves.

If there is still more life left in your gloves, then try washing them using our washing instructions. Also, there are commercial laundering companies that facilitate washing PPE.

Goatskin is traditionally viewed as the most naturally water-resistant leather available, but an inner membrane liner is the surest and easiest way to waterproof leather gloves. There are new treatments like block oil and water that can provide waterproofing protection. Both of these types of gloves are covered in our Speciality Leather Glove section.

We recommend deerskin leather as the softest, most luxurious leather available on the market. Elkskin and goatskin are a strong second to deerskin.

A lot! You can find this information covered on each Leather Work Glove page, and we also include it in our Leather 101 page.

Check out our Heavy-Duty Leather Work Glove page. Our Big Jake® glove is our toughest offering!.

Electrical work is dangerous and requires rubber protectors, first and foremost. Leather work gloves serve as only a secondary barrier over the top of the rubber protectors.

We highlight many of the industries and applications for leather gloves on our main Leather Work Glove page.

It takes leather around 25-50 years to decompose. Tanned leather gloves typically take a little longer as a result of the tanning process

Natural leather gloves have an inconsistent pattern, whereas synthetic leather will be more consistent.

Do you have a question we have not answered? No worries, we have an internal team ready to answer any questions you have.Please leave us feedback here with your question, and we will be in touch.

Click one of the links below to learn more about that topic.