Before we get into talking about high-performance polyethylene (HPPE) and ultra-high—molecular weight polyethylene (UHMWPE), which are two of the most advanced fibers used in MCR Safety’s cut-resistant gloves, we’ve got to talk science in the next couple of sections. We are going to take a closer look at what exactly polyethylene is and how it can be used in everyday applications. If you think you know everything you’ve ever wanted to know about polyethylene, we do give you the chance to bypass the education section and go directly to our HPPE gloves page. Just click on the below Hypermax® and DSM Dyneema® images.

Plastics make up many 21st century products, including PPE

Some of you may already know this information, or you simply want to purchase a pair of highly cut-resistant gloves to face extreme cut hazards. Either way, we want to give you the option of learning more about plastics, specifically polyethylene, or heading directly to MCR Safety’s extensive line of cut-resistant gloves. Whichever option you choose, first check out some of the variations of polyethylene that are used in PPE.

As you can see from this partial list of polyethylene products, MCR Safety uses a host of different types of polyethylene to produce our gloves and PPE. Before you head off into one of the individual HPPE technology pages, here’s a quick run-down of the difference between the industry leading brands we utilize:

Hypermax 1.0 and 2.0 HPPE: Both of these polyethylene-based fibers provide users with high-performing cut-resistance gloves that offer exceptional comfort and are also cost-effective. The only difference between these two HPPE technologies is that the 2.0 fibers utilize UHWMPE and can achieve higher cut levels without compromising dexterity.

DSM Diamond Dyneema: DSM Diamond Dyneema is a super-strong polyethylene-based fiber that provides the highest comfort level of all HPPE cut-resistance gloves. DSM Dyneema literally forged this industry into what it is today. Just keep in mind, you pay a premium for the comfort. For those wearing gloves every day, the premium cost may be justified for the comfort they offer.

Either technology provides users with excellent gloves for protection against cut hazards. We offer comparison data from our very own ITC lab below. We encourage users to try both versions before making a long-term decision.

Before you leave this page for either HPPE brand, make sure you’re aware of the other factors that affect a glove’s cost: feel and performance. Guage is a factor that affects both the feel and the performance, and therefore the price. If you’re interested in learning more about this glove attribute and polyethylene, keep reading.

If you’re ready to check out our HPPE offerings, jump to the HPPE technology page you prefer. You can now go directly to either one of our different HPPE fiber brands by clicking the images below.

What is Polyethylene?

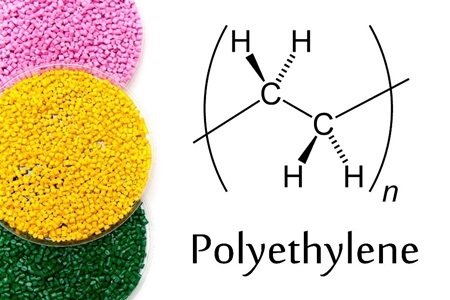

It’s time for the science lesson! We said we were going to bring science into the discussion here, and we don’t disappoint. Polyethylene is a thermoplastic polymer, polyolefin to be exact, that consists of many ethylene monomers bonded together. Its molecules are a long chain of carbon atoms, with two hydrogen atoms attached to each carbon atom. When you look at the image above, its structure is simple by nature. In fact, it is one of the simplest commercial polymers.

For those who are still tormented by memories of high school chemistry class, we’re stopping here. We know most of you who are reading are just trying to figure out which high-performing cut-resistant gloves are best for you, not looking for a recap on high school chemistry. Just remember, as we mentioned above, polyethene is merely a plastic. It’s a polymer known for versatility and recyclability and although it comes offered under different names and touts different advantages depending on the marketing, it’s simply plastic derived from materials found in nature.

Different Types of Polyethylene

There are approximately 80 million tons of polyethylene produced each year. As you know by now, MCR Safety is guilty as charged when it comes to being a contributor to polyethylene usage. We use it to create gloves that protect people all over the world.

As we explained in our mini chemistry lesson, there are different types of polyethylene depending on how the molecules arrange themselves and branch together. We’re not going to cover all the different types, as there are many, but we would like to take a moment to expound upon the ones you’re likely to encounter in your MCR Safety glove selection search.

Polyethylene General Purpose Gloves

HDPE

When there is no additional branching after the initial molecular bond, the polyethylene is called high-density polyethylene (HDPE). This type of plastic is used in milk jugs and in MCR Safety’s disposable polyethylene gloves, shown above. Our 5040 disposable gloves use HDPE because it is a versatile material with excellent tensile strength, and it is food-friendly. Next time you’re in line at Subway, look at the gloves the worker preparing your sandwich is wearing; they will most likely be HDPE disposable gloves.

LDPE and LLDPE

When longer branches of polyethene come together, they form a softer low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE). This plastic is very flexible and provides a good water barrier. You will find variations for one-time use disposable gloves that use both LDPE and HDPE. One non-glove example of LDPE in the market is squeeze bottles.

High-Performance Cut-Resistant Gloves

When creating strong HPPE fibers, the molecular chains must be stretched, oriented, and crystallized in the direction of the fiber. The gel spinning process achieves this requirement, which is discussed in our next section, the manufacturing section.

UHMWPE was originally developed in the 1950’s, by Ruhrchemie AG and was introduced in 1955 at the K55 polymer trade show. It’s only been used in the glove industry for a little over a decade now.

Here are the two types of polyethylene we classify that make up cut-resistant gloves:

HPPE

High-performance polyethylene is a thermoplastic polyethylene-based fiber utilized in MCR Safety’s cut-resistant gloves. HPPE is the term most recognized by industries; however, high-modulus fibers are also referred to by the names of high-modulus polyethylene (HMPE) or extended chain polyethylene (ECPE). HPPE has stuck for most because it’s what goes into making high-performance cut-resistant gloves. With unmatched comfort, flexibility, and high strength properties, users have 100% adopted this material as their preference in cut-resistant gloves.

HPPE fibers are strong and offer extremely high-tenacity. Pound-for-pound, they are up to 15X stronger than steel, providing excellent protection from abrasion injuries and cut injuries. You can find HPPE used in many products like fishing line and netting, marine cables, concrete reinforcement, sail cloth, and medical implants. Our Hypermax 1.0 gloves utilize HPPE.

Fishing line is made with HPPE

UHMWPE

Ultra-high molecular weight polyethylene is a subset of thermoplastic polyethylene and is used for high-performance applications like medical devices, bullet proof vests, and some of MCR Safety’s highest-rated cut-resistant gloves. It’s extremely long chains, with a molecular weight numbering between 2 and 6 million, strengthen the intermolecular interactions, resulting in an extremely tough material. UHMWPE is tougher than standard HPPE, which is why higher cut-resistant levels are achieved.

MCR Safety’s Cut Pro gloves with Hypermax® 2.0 incorporate this type of filament, In addition, MCR Safety Cut Pro gloves made from Spectra and DSM Diamond Dyneema utilize UHMWPE based fibers.

Key Features of Both HPPE and UHMWPE

- High tensile strength

- High abrasion-resistance

- Impact-resistant, absorbs high amounts of energy

- Low moisture absorption

- Chemical-resistant (excluding oxidizing acids)

- Resistant to UV radiation

We discuss how these different types of fibers are produced in the next section. Some of the manufacturing processes mentioned next are used to make other polymer-based MCR Safety products aside from just HPPE cut-resistant gloves.

The Manufacturing Process - Polymers into Fibers

Synthetic fibers are typically polymers that are spun into filaments by a production method referred to as melt, dry, gel, or wet spinning processes. Each process is a little different, so we’ll explain them below.

To ultimately emerge as workable yarn that can be used in gloves, polymers must first be converted into a fluid state, giving them additional fiber strength and high tenacity, and then transformed into a fiber. This occurs by either melting the polymer, dissolving the solvent, or chemically treating it.

Polyethylene filament production shown in image. We touch on the different processes below. HPPE ultimately becomes a filament yarn via the gel spinning process.

In addition, many of the materials that make up MCR Safety’s product line are formed via one of the spinning processes, so we’ll highlight each of them next.

Spinning Polymers in Fibers and Material

Below are the different types of spinning used to make fibers, materials, and polyethylene. Keep in mind, fiber manufacturers can use different spinning processes for the same fiber. For example, modacrylic can be made using either dry spinning or wet spinning. Here’s a brief explanation of the processes:

Dry Spinning

The polymer is dissolved in its solvent, evaporating the solvent into a stream of air or gas. This process is used to create acetate, modacrylic, and spandex. All three materials are used in creating MCR Safety PPE in the form of face shields, FR hi-vis vests, gloves, and aprons.

MCR Safety manufacturers the majority of our line of face shields at our U.S. plant

Gel Spinning

Polymer chains are bound together in a liquid crystal form before extrusion. This is the spinning process used to make most HPPE and UHMWPE. Keep in mind, there are other variables that make up a final HPPE solution produced by suppliers. This is why DSM Dyneema fiber is considered the coolest, most comfortable UHMWPE on the market.

92763 uses UHMWPE, which is a gel spun polyethylene fiber.

Melt Spinning

A polymer substance is melted for extrusion through a spinneret, a plate with a number of small holes, before being directly cooled. Nylon and polyester are created from this method. The majority of MCR Safety’s general-purpose gloves use liners made from nylon or polyester, which becomes yarn via this process.

N9696 utilizes an 18-gauge nylon shell to bring you a 30% lighter glove compared to other general-purpose nylon shells. Before it becomes a glove, the fiber in the shell has gone through melt spinning.

Wet Spinning

Fiber-forming substances are dissolved in a solvent, are submerged in a chemical bath, then emerge from a solution into a solidified polymer fiber. Many of MCR Safety’s cut-resistant gloves that incorporate aramid fibers use this process. Like UHWMPE, high-strength aramids use a gel spinning process, too. This is what separates different fiber companies from one another: the process and additional minerals added.

MCR Safety’s Cut Pro Glove Made with DuPont™ Kevlar®

After the spinning process, the fibers are transformed into yarn by winding numerous continuous fibers together into one single uniform piece of yarn. One fact around this point. MCR Safety doesn’t get involved with the spinning of aramids, however, we’re the only DuPont™ Kevlar® licensee to take spun Kevlar® and spin it into a final cut-resistant fiber.

Once into a workable fiber for glove production, HPPE and UHMWPE yarn is sent to our MCR Safety factory in Mexico, to the NXG factory, and to factory partners located all over the world. It’s this final yarn product that keeps workers’ hands protected from the numerous extreme cut hazards they face on the job every day.

HPPE Products - Cut-resistant Gloves

We know we’ve hit you with a lot of information. Our goal is simply to help inform you of these elements regarding polyethylene and manufacturing, so that when you hear companies use industry terms like “gel spun,” “HPPE,” or “UHWMPE,” you know what they’re talking about. We do want to mention here that HPPE based products have a low-melting point and offer limited contact heat protection. So, we do encourage you to visiting some of our technologies that offer heat and cut protection.

For anyone interested in simply cut-resistant products, we stress that you should focus on the performance of the product first and foremost. One way to do this is to determine the ANSI Cut Score level a glove achieves.

From there, decide on the next layer of attributes that may be important to you or critical to your work environment: thinner gauge for comfort, coatings, fiber options, features like reinforced thumb crotch, etc. Regardless of those extra features, it all comes down to this: if you are wearing a higher ANSI-rated cut glove, you’re protected in better PPE, case closed.

With that said, we’ve got a tool to help you quickly find the performance you require in your gloves. Then, our powerful catalog filtering system can help you find those extra features you might be seeking.

| Extreme Cut Hazards | A9: 6,000+ gram to cut |

|---|---|

| Very High Cut Hazards | A8: 5,000 to 5,999 gram to cut |

| High Cut Hazards | A7: 4,000 to 4,999 gram to cut |

| Heavy Cut Hazards | A6: 3,000 to 3,999 gram to cut |

| Medium to Heavy Cut Hazards | A5: 2,200 to 2,999 gram to cut |

| Medium Cut Hazards | A4: 1,500 to 2,199 gram to cut |

| Light to Medium Cut Hazards | A3: 1,000 to 1,499 gram to cut |

| Light Cut Hazards | A2: 500 to 999 gram to cut |

HPPE Performance Comparison Chart

We’ve aligned the gauge and coating options, so this an accurate side-by-side comparison. Note the high-performance scores of the Hypermax 1.0 and Hypermax 2.0 technology. Their cut-resistant scores prove they offer excellent cut protection and at a competitive price point too!

| Gauge | ANSIC Cut Level | ANSI Cut Gram WT. | *Polyethylene | Nitrile | Nitrile Foam | PU | Hypermax 1.0 | Hypermax 2.0 | DSM Diamond Dyneema | Part # | ANSI Cut TAF REF Number |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 Gauge Nitrile | A6 | 3999 | HPPE | X | X | 92720HVL | 2419-1 | ||||

| 10 Gauge Nitrile | A6 | 3254 | UHMWPE | X | X | 9672DT5L | 1170-1 | ||||

| 13 Gauge PU | A3 | 1450 | HPPE | X | X | 92752L | 2592-1 | ||||

| 13 Gauge PU | A3 | 1380 | UHMWPE | X | X | 9672L | 2618-1 | ||||

| 13 Gauge PU | A6 | 3723 | UHMWPE | X | X | 92793PUL | 2732-1 | ||||

| 13 Gauge Nitrile | A3 | 1110 | UHMWPE | X | X | N9676DTL | 1951-1 | ||||

| 13 Gauge Nitrile | A3 | 1398 | UHMWPE | X | X | 92715NFL | 2701-1 | ||||

| 13 Gauge Nitrile | A3 | 6849 | UHMWPE | X | X | 92735NL | 2420-1 | ||||

| 18 Gauge PU | A2 | 695 | HPPE | X | X | 92718PUL | 2158-1 | ||||

| 18 Gauge PU | A2 | 680 | UHMWPE | X | X | 9672DT2L |

1658-1 |

||||

| 18 Gauge PU | A5 | 3264 | UHMWPE | X | X | 96738PUL |

2703-1 |

MCR Safety's Value to Customers

The last take way, and one that hopefully resonates with all who are reading, is this: there are many companies today’s now offering cut-resistant gloves, which makes the process of purchasing gloves even more of a challenge. We know it’s a challenge, as we’re in constant contact with our customers and hear it.

As you shop around, ask yourself these questions:

- When it comes to your body, do you really want to take shortcuts or chances with unfamiliar brands?

- Do you want to take chances with products you’re not familiar with or with companies that don’t have dedicated resources pages like this one to help educate and give you the facts?

- Does the company supplying the products focus on manufacturing only PPE?

- Does the product you’re purchasing now, or are considering purchasing in the future, have the same level of commitment to protecting people that MCR Safety does?

At MCR Safety, we’re not polyethylene manufacturers. We’re not selling a laundry list of plastic products: trash cans, red tubing, etc. Instead, we focus on one thing and one thing only: protecting people. We make high-quality PPE that companies, workers, and families rely on every day to keep people safe.

Protecting people with top-quality PPE is what we do and we do this by manufacturing, producing, and supplying premier safety glasses, safety gloves, safety garments, and FR clothing. That’s it. There are no other products offered under the MCR Safety product lineup.

You might ask, what does this mean to me? What it means is that MCR Safety goes the extra mile for you to make sure you are thoroughly protected and are purchasing the best PPE available. We have identified four product areas that we ensure are thoroughly tested on the front end and on the back end in our ITC lab. Within the scope of cut-resistant gloves, we are routinely testing our own gloves, along with competitors’ gloves and any other glove a user sends us for quality validation.